Manufacturing method of display panel, display panel and display device

A technology of a display panel and a manufacturing method, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of consumers' simplicity and contradiction, and achieve the effect of realizing a borderless design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

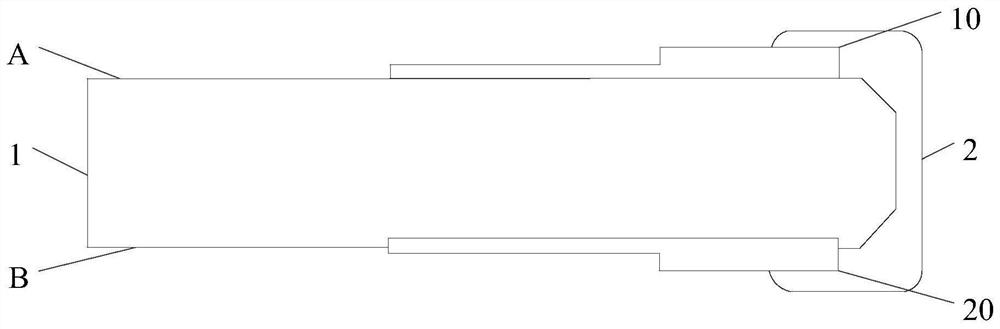

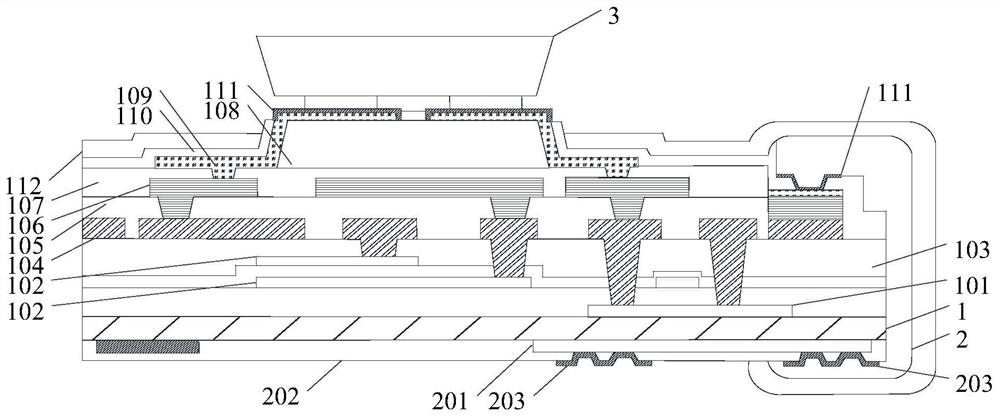

[0025] Embodiment 1 of the present invention provides a method for manufacturing a display panel, including: a substrate 1, the substrate 1 has a first surface A and a second surface B opposite to the first surface A, refer to figure 1 As shown, its production method may include:

[0026] depositing an array layer 10 on the first surface A;

[0027] depositing a chip-on-film layer 20 on the second surface B;

[0028] A connection line 2 is provided on the side surface of the substrate 1 , and two ends of the connection line 2 are respectively connected to the array layer 10 and the chip-on-film layer 20 .

[0029] Specifically, the substrate 1 can be made of a high-temperature resistant material to ensure that the substrate 1 can withstand high-temperature baking during high-temperature annealing when the array layer 10 is deposited; the connecting wire 2 can be a metal wire, such as a wire made of silver material; the connecting wire 2 It can be attached to the side surface...

Embodiment 2

[0088] Based on the same inventive concept, the second embodiment of the present invention provides a display panel, which is manufactured according to the above manufacturing method, refer to figure 1 shown, the display panel includes:

[0089] The substrate 1 has a first surface A and a second surface B opposite to the first surface A, the first surface A is provided with an array layer 10, and the second surface B is provided with a chip-on-film layer 20;

[0090] The connection line 2 is disposed on the side surface of the substrate 1 , and two ends of the connection line 2 are electrically connected to the array layer 10 and the chip-on-film layer 20 respectively.

[0091] Specifically, by disposing the array layer 10 on the first surface A of the substrate 1, and disposing the chip-on-film layer 20 on the second surface B of the substrate 1, the first surface A and the second surface B are opposite to each other. At the same time, the side surface of the substrate 1 is ...

Embodiment 3

[0097] Based on the same inventive concept, Embodiment 3 of the present invention provides a display device, which includes: the above-mentioned display panel.

[0098] Specifically, the display device may be any product or component with a display function, such as a tablet computer, a television, electronic paper, a mobile phone, a monitor, a notebook computer, a digital photo frame, and a navigator.

[0099] The display device provided in this embodiment can execute the above method embodiments, and the implementation principles and technical effects thereof are similar, and details are not described herein again.

[0100] In the description of the present invention, it should be understood that the terms "first" and "second" are only used for description purposes, and cannot be interpreted as indicating or implying relative importance or the number of indicated technical features. Thus, a feature delimited with "first", "second" may expressly or implicitly include at least o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com