Forming method of polarizing sheet and retarding sheet with continuously changed shaft

A polarizer and retarder technology, applied in optics, shading screens, nonlinear optics, etc., can solve the problems of blocked full-window view and lack of effectiveness of glass polishing methods, and achieve the effect of balanced view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

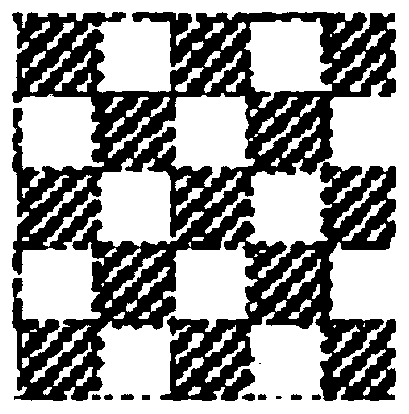

[0110] see Figure 6 In Embodiment 1, a photo-alignment layer with a continuously changing alignment direction is formed on the substrate 50 by a continuous scanning method.

[0111] First, a photo-alignment material is coated on the substrate 50 . The substrate 50 coated with the photo-alignment material is placed on the linear moving device, and the side coated with the photo-alignment material faces the exposure light source 80 , wherein the exposure light source 80 can be an ultraviolet or blue light source 80 .

[0112] Between the light source 80 and the substrate 50, a polarizer 90 and a blocking sheet 100 with a slit perpendicular to the direction of movement of the substrate 50 are provided so that the light can pass through the polarizer 90 slit to the substrate 50 in turn. Expose the photo-alignment material on it. It should be noted that the relative positions of the polarizer 90 and the blocking sheet 100 are not limited, that is, the polarizer 90 may be located...

Embodiment 2

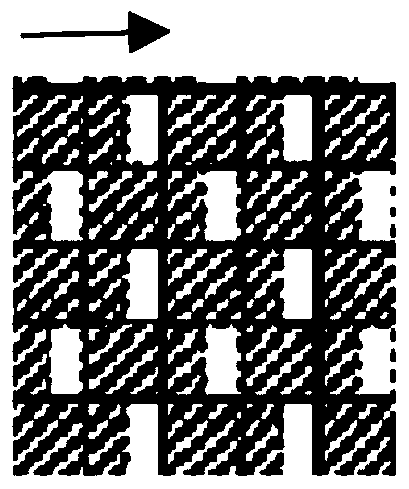

[0117] see Figure 7 , in order to obtain a photo-alignment layer with a continuously changing alignment direction, a half-wave retarder can also be used as a replica master for separate exposure, the specific method is as follows.

[0118]First, a photo-alignment material is coated on the substrate 50 . The substrate 50 coated with the photo-alignment material is placed on the linear moving device, and the side coated with the photo-alignment material faces the exposure light source 80, wherein the exposure light source 80 may be an ultraviolet or blue light source.

[0119] Between the exposure light source 80 and the substrate 50, a linear polarizer 120 and a half-wave plate 130 with a continuous axis change are arranged in sequence, so that the light emitted by the light source 80 passes through the linear polarizer 120 and the half-wave plate 130 with an axis change in sequence. The substrate 50 is irradiated to form a continuously changing axis photo-alignment layer. I...

Embodiment 3

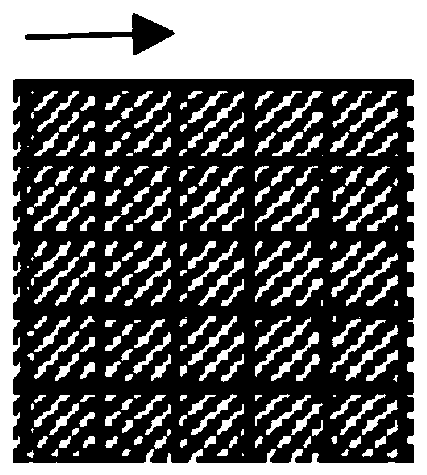

[0122] like Figure 8 As shown, it is also possible to use a planar aligned wedge-shaped unit instead of the above-mentioned half-wave plate with continuous axis variation as a master. Wherein, the planar aligned wedge-shaped unit has a spacer 140 and a glass substrate 150 with a photo-alignment layer, wherein liquid crystal molecules are enclosed in the glass substrate 150 . The wedge-shaped unit has a continuously variable unit thickness, so that the phase change introduced on the polarized input light passing through the wedge-shaped unit can be continuously varied, usually requiring 0 to 2π. The specific implementation method is as follows.

[0123] First, a photo-alignment material is coated on the substrate 50 . The substrate 50 coated with the photo-alignment material is placed on the linear moving device, and the side coated with the photo-alignment material faces the exposure light source 80, wherein the exposure light source 80 may be an ultraviolet or blue light s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com