Spraying structure of sink dishwasher

A technology for dishwashers and sinks, applied to tableware washing machines/rinsing machines, tableware washing machines/rinsing and rinsing machine parts, cleaning equipment, etc., which can solve the problems of static spray coordination, inner tank space occupation, and high cost , to achieve the effect of improving the washing effect, increasing the injection pressure and shortening the washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

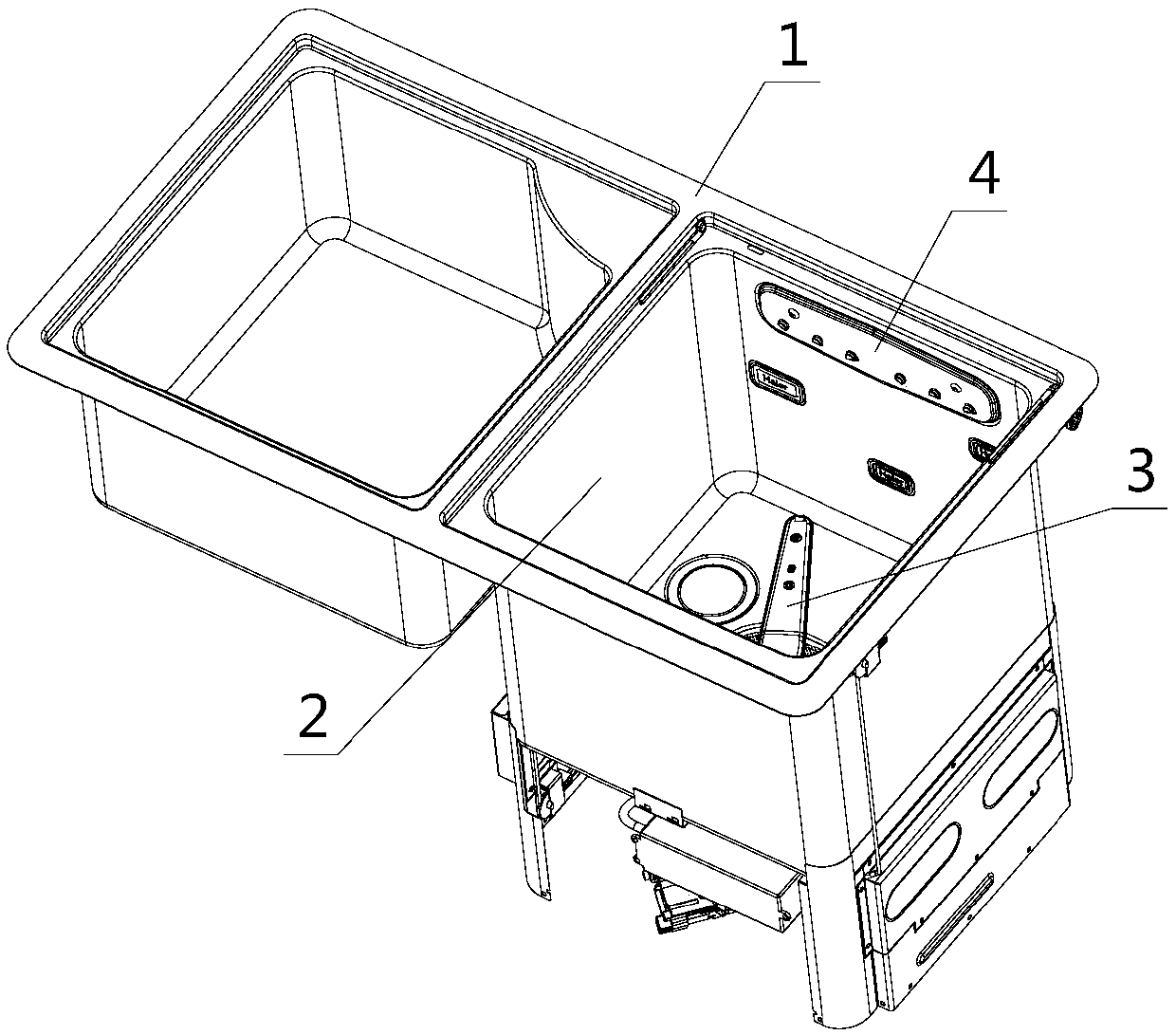

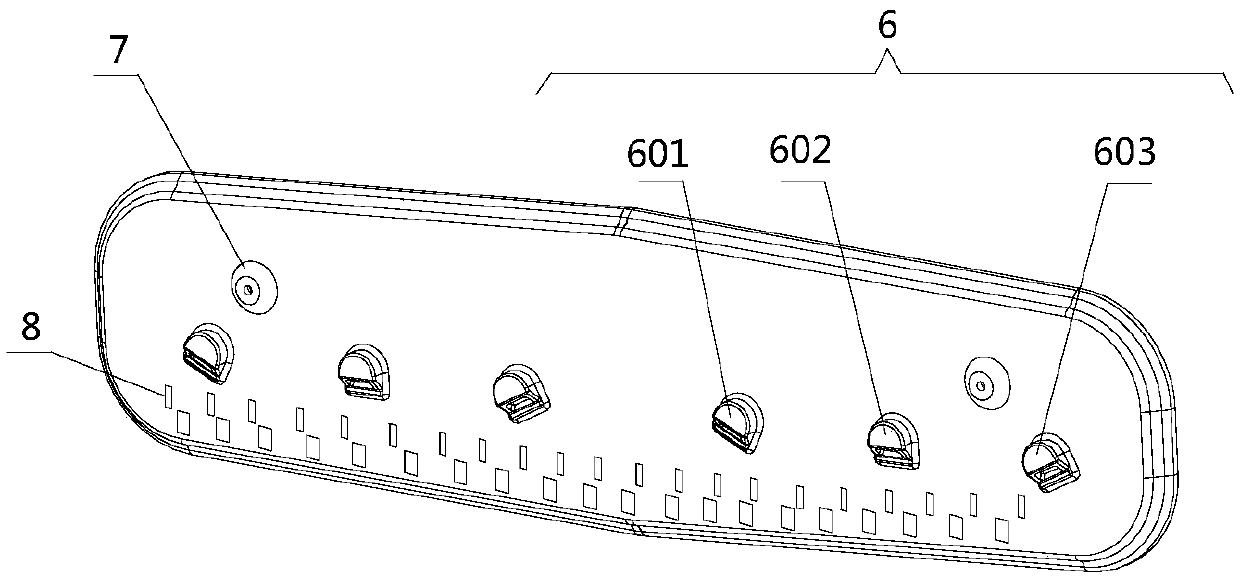

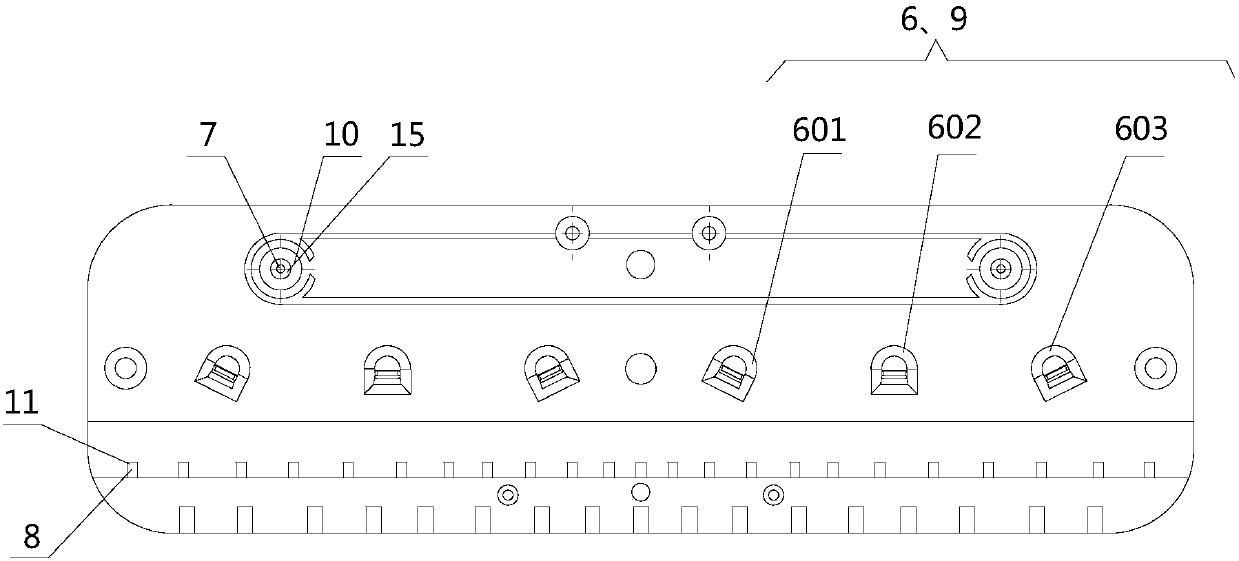

[0048] Such as Figure 1 to Figure 4 As shown, the spray structure of a sink dishwasher described in this embodiment includes a movable spray arm 3 arranged at the bottom of the tank body 2 of the sink dishwasher 1 for rotatable spraying; At least one static spray arm 4 for static directional spraying on the side wall of the tank body 2; at least one set of first spray units 5 are arranged on the movable spray arm 3, and at least one set of first spray units 5 are arranged on the static spray arm 4 The second spray unit 6; the static spray arm 4 has a built-in booster port 7 and a steam generating port 8; the second spray unit 6 includes a first spray hole 601, a second spray hole 602 and a third spray hole hole 603; the spray angles of the first spray hole 601, the second spray hole 602 and the third spray hole 603 do not interfere with each other; the booster port 7 is provided with a booster sheet 15, and the booster sheet 15 This increases the pressure of the passing wate...

Embodiment 2

[0050] Such as Figure 1 to Figure 4 As shown, this embodiment is a further limitation of the first embodiment above. The second spray unit 6 in the spray structure of a sink dishwasher described in this embodiment is connected to The water inlet pipe (not shown in the accompanying drawings), and then the water flow is sprayed out of the spray hole; wherein, when the water flow passes through the spray hole and the connecting pipe (not shown in the accompanying drawings), a spray pipeline is formed, and the spray pipeline is the first Wash chamber 9.

Embodiment 3

[0052] Such as Figure 1 to Figure 4 As shown, this embodiment is a further limitation of the above-mentioned embodiment one or two. The booster port 7 in the spray structure of a sink dishwasher described in this embodiment is connected through a connecting pipe (not shown in the drawings). The water inlet pipe (not shown in the accompanying drawings), the diameter of the pipe connected to the booster port 7 changes from large to small to form a further pressurized structure, and the water flow through the booster port 7 becomes a form of water mist combination, realizing the effect of scouring and soaking Features.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com