A magnetic filter device for separating magnetized particles from fluid

A magnetic filtration and fluid technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve problems such as high cost, and achieve the effects of easy maintenance, simple operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

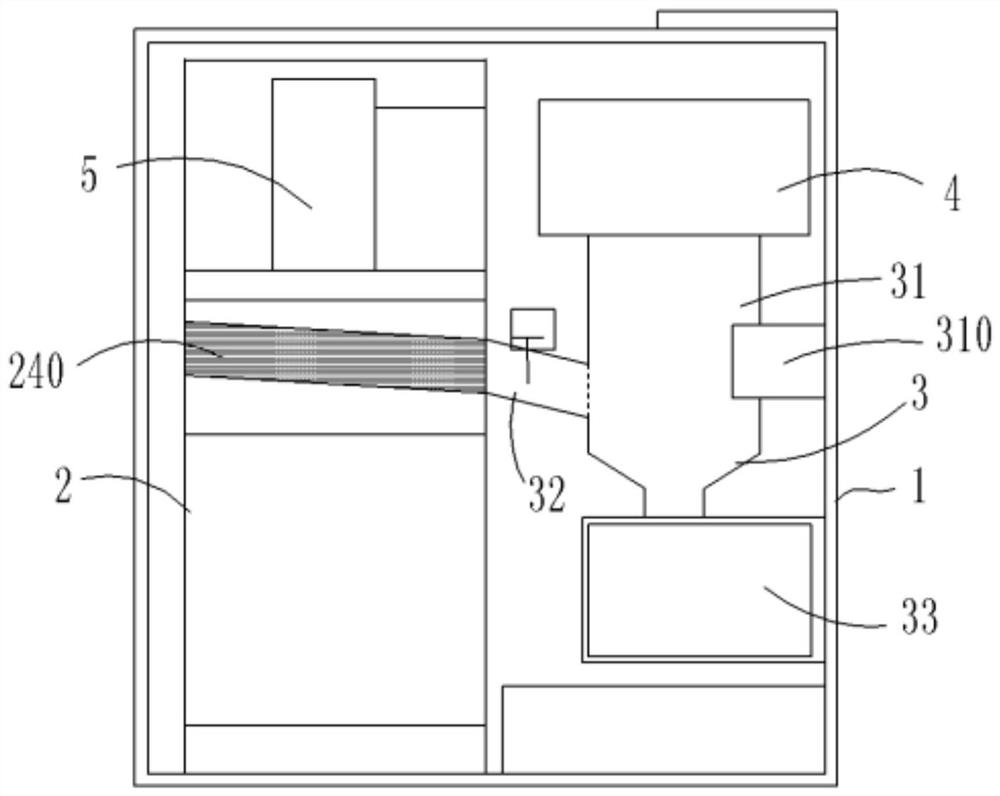

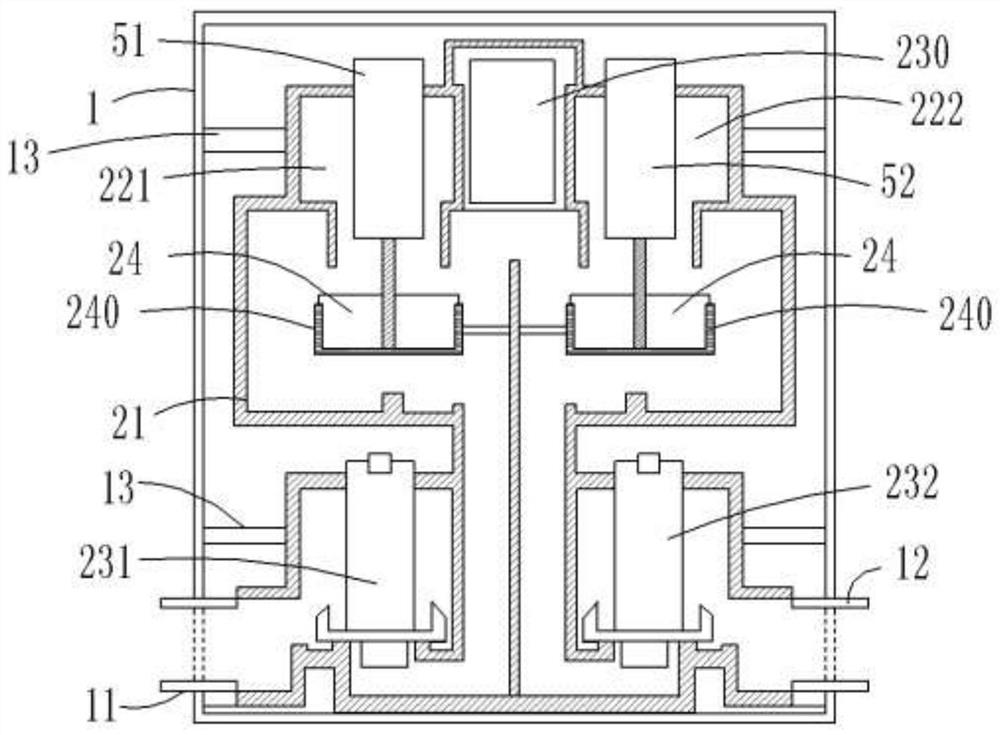

[0024] Embodiment 1: as figure 1 , 2 A magnetic filter device for separating magnetized particles from fluid is shown, including a housing 1, a fluid channel 2, a collecting device 3, a dispersing device 4, an electromagnet device 5, a control device and a power supply device;

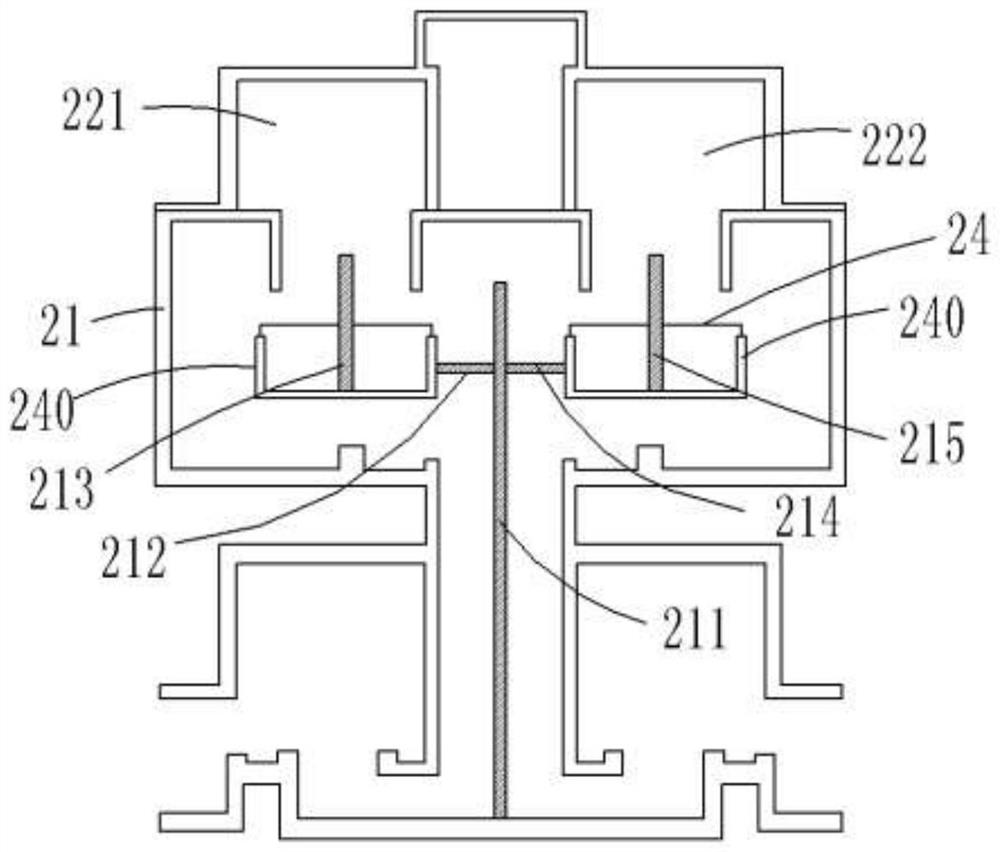

[0025] Such as figure 2 , 3 , 4, the fluid channel 2 is set at the front end of the housing 1, the housing 1 is provided with a fluid inlet 11 and a fluid outlet 12, the fluid inlet 11 is connected to the water inlet of the fluid channel 2, and the fluid outlet 12 is connected to the drain end of the fluid channel 2; the fluid channel 2 has an "I"-shaped structure, and the fluid channel 2 is provided with a first isolation plate 211, a second isolation plate 212, a third isolation plate 213, and a fourth isolation plate 214 , the fifth isolation plate 215; the left and right sides of the upper end of the fluid channel 2 are respectively provided with a left end magnetic filter cavity 221 and a righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com