Spray and overflow integrated structure of sink dishwasher

A dishwasher and sink technology, which is applied to the washing machine/washing machine for tableware, the parts of the washing machine/rinsing washing machine for tableware, cleaning equipment, etc. , to achieve the effect of increasing the injection pressure, shortening the washing time, and increasing the coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

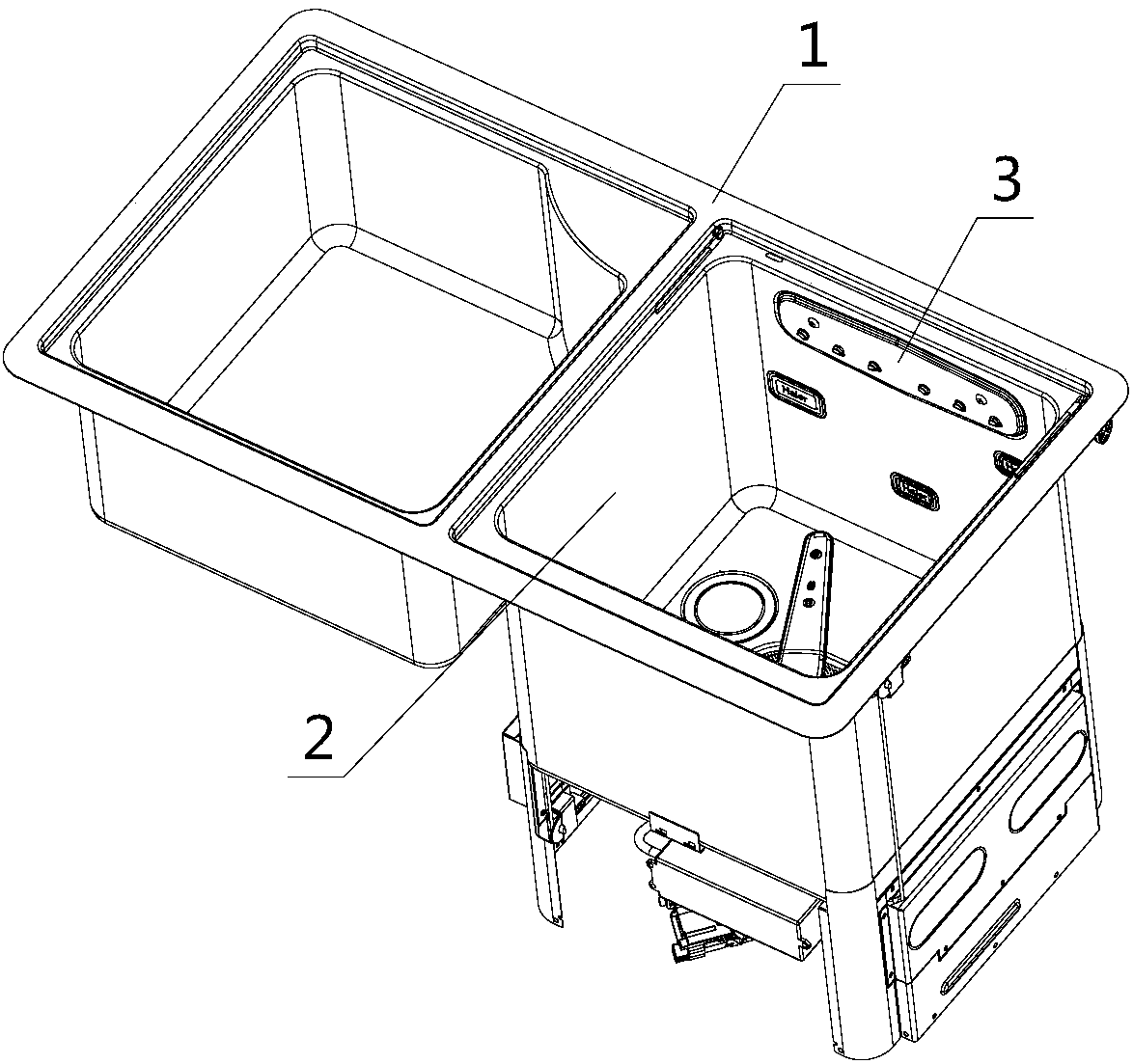

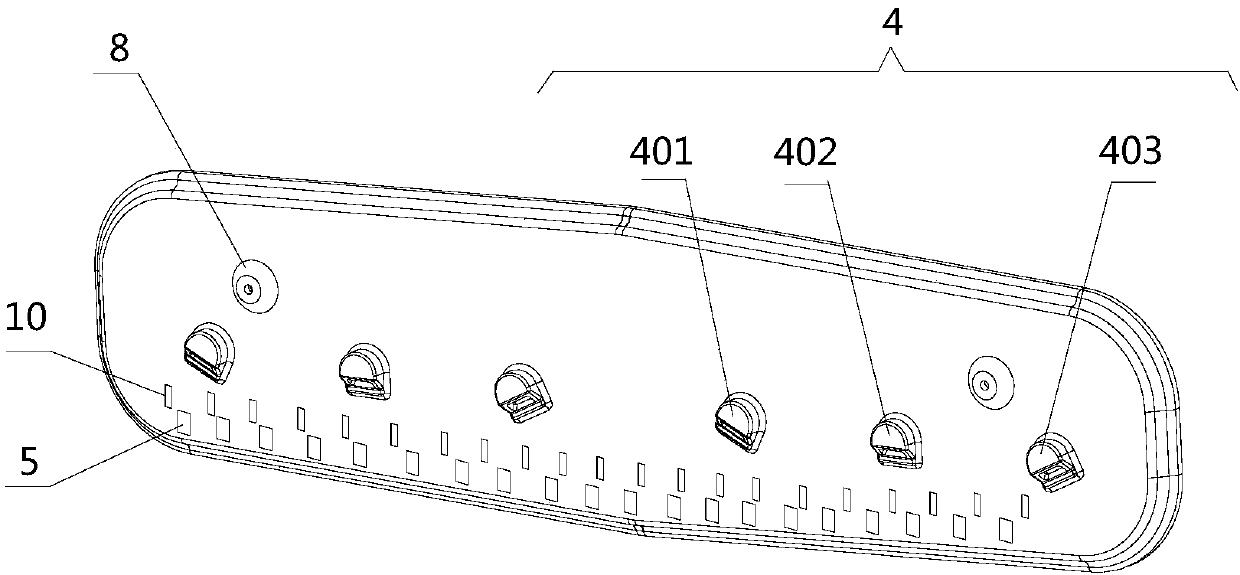

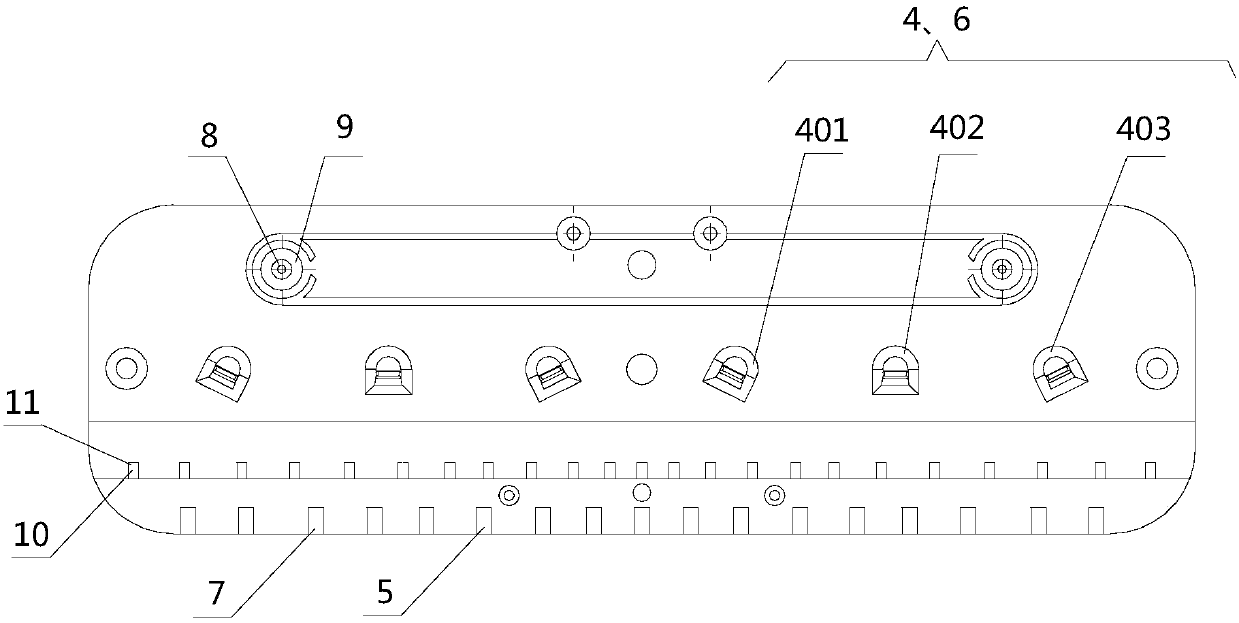

[0044] Such as Figure 1 to Figure 3 As shown, a sink dishwasher 1 described in this embodiment has a spray and overflow integrated structure, including a dynamic spray arm (not shown in the drawings) and a static spray arm 3, and the static spray arm 3 includes At least one set of static spray assembly 4; the static spray assembly 4 includes a first spray hole 401, a second spray hole 402 and a third spray hole 403; the first spray hole 401, the second spray hole The spraying angles of the shower hole 402 and the third spray hole 403 do not interfere with each other. The multi-angle spray cleaning enables the washing process to cover the dead corner of the washing, improves the washing effect, and solves the problem of washing dishes on the second shelf. The first washing chamber 6 is formed by the spraying pipelines in the first spraying hole 401 , the second spraying hole 402 and the third spraying hole 403 .

[0045] In addition, the static spray has at least one built-in...

Embodiment 2

[0049] Such as Figure 1 to Figure 3 As shown, this embodiment is a further limitation of the first embodiment above. The static spray arm 3 of the sink dishwasher 1 in this embodiment also includes a distance from the static spray arm 3 to the bottom of the tank body 2 greater than that of the static spray arm 3 . There is at least one booster port 8 at the distance from the assembly 4 to the bottom of the tank body 2 , and the booster injection pipeline in the booster port 8 forms a second washing chamber 9 .

[0050] A static spray arm 3 is arranged on the side of the sink dishwasher 1 described in this embodiment, and the static spray arm 3 is combined with a dynamic spray arm (not shown in the accompanying drawings) to perform multi-angle cleaning operations, which effectively will The cleaning and disinfection of the dead corners of the tableware that have not been cleaned and the tableware (the second shelf) in the area covered by the tableware, the washing area is enla...

Embodiment 3

[0052] Such as Figure 1 to Figure 3 As shown, this embodiment is a further limitation of the first embodiment above. The static spray arm 3 of the sink dishwasher 1 in this embodiment also includes a static spray arm 3 that is arranged in the static spray arm 3 and the distance from the bottom of the tank body 2 is less than the static spray arm 3. There is at least one steam generating port 10 at the distance from the component 4 to the bottom of the tank body 2 , and the steam injection pipeline in the steam generating port 10 forms a steam cavity 11 .

[0053] A static spray arm 3 is arranged on the side of the sink dishwasher 1 described in this embodiment, and the static spray arm 3 is combined with a dynamic spray arm (not shown in the accompanying drawings) to perform multi-angle cleaning operations, which effectively will The cleaning and disinfection of the tableware (the second shelf) in the dead corner of the washing and the area covered by the tableware, the washi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com