Appearance detection system based on machine vision

Appearance inspection and machine vision technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of complicated shooting process, increased shooting cost, lack of universality of the object to be shot, etc., to simplify the shooting process and reduce the shooting cost. , the effect of reducing the number and time of shots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

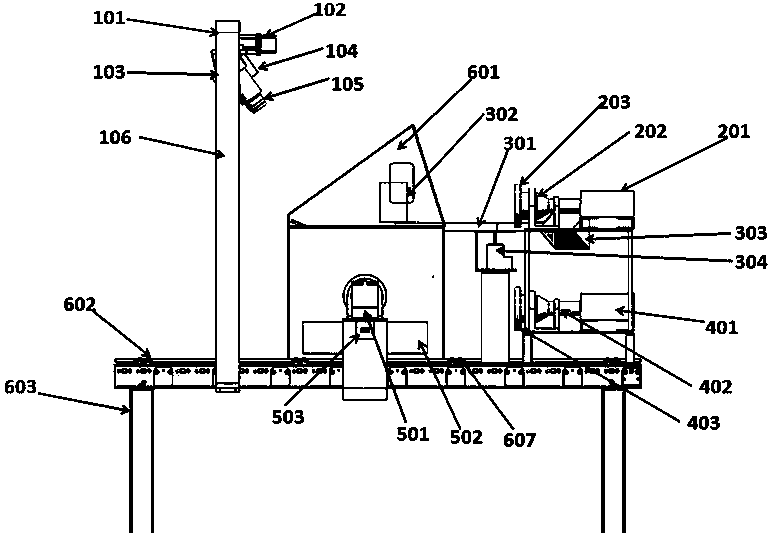

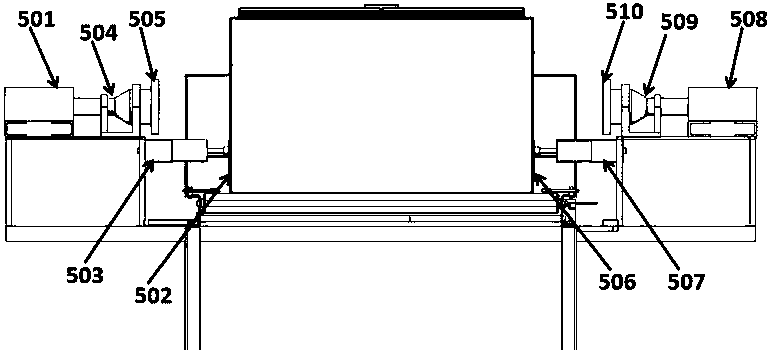

[0025] like figure 1 and figure 2 As shown, an appearance inspection system based on machine vision, the system includes a line scan camera scanning system, a transmission system and several shooting systems, wherein:

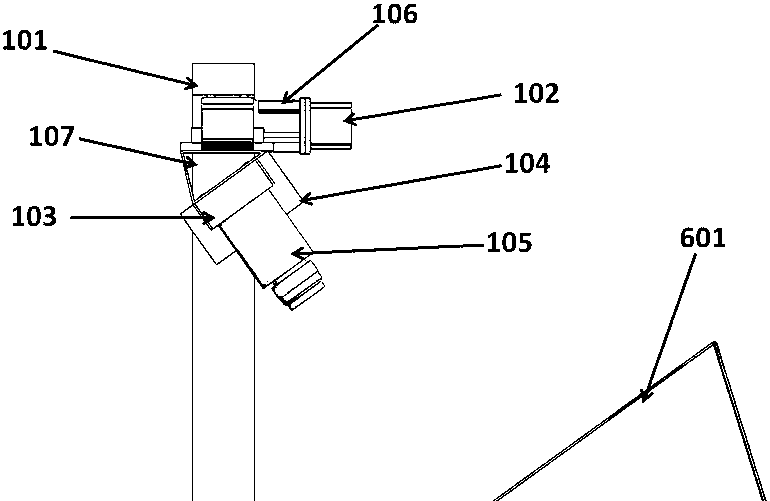

[0026] The line scan camera scanning system includes a scanning and shooting component and a horizontal moving component, the scanning and shooting component is arranged on the horizontal moving component, and is driven by the horizontal moving component to perform horizontal scanning and shooting in the horizontal direction;

[0027] Several said photographing systems are respectively arranged at suitable positions close to the object to be photographed, and it is advisable to be able to photograph the outer and inner sides of the object to be photographed. Each photographing system includes an area array camera ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com