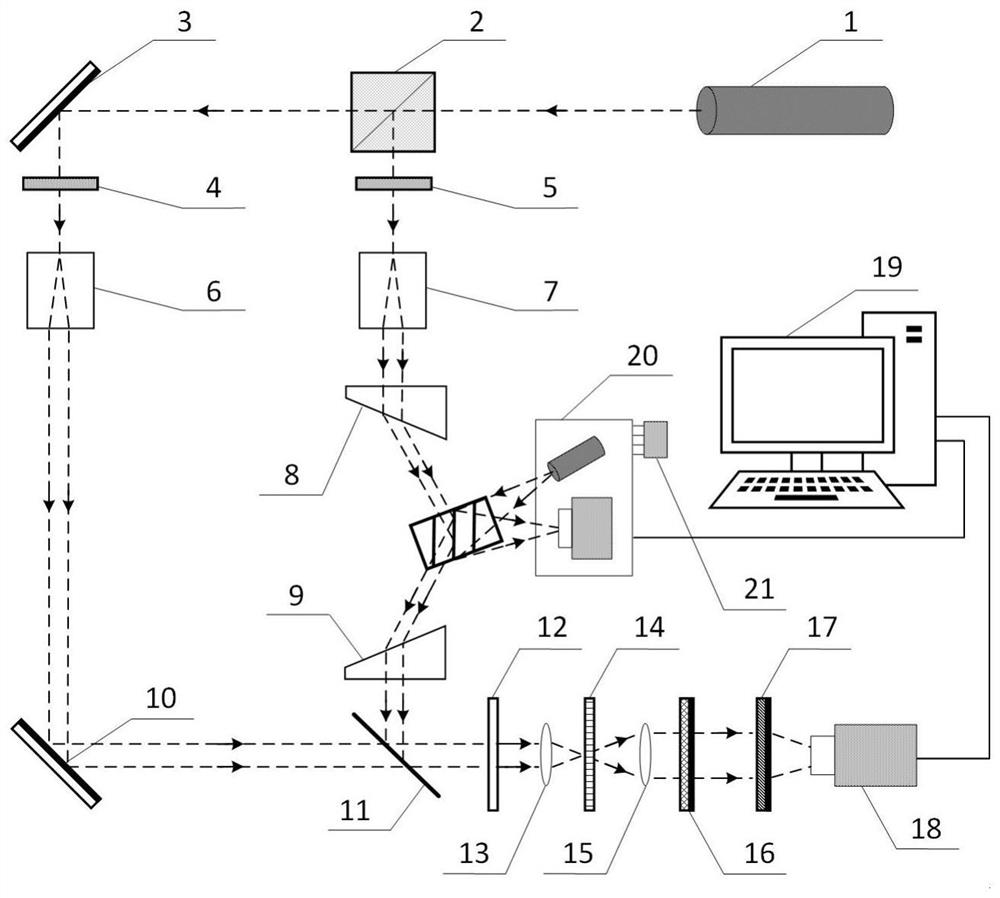

Spiral curved surface shape error measurement method based on dual-optical-path synchronous phase shift interference

A helical surface, synchronous phase shift technology, applied in the field of optical measurement, can solve the problems of helical surface shape error, inability to achieve full field measurement, low precision, etc., to achieve a large measurement range, increase anti-interference ability, and simplify the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for measuring the shape error of a helical curved surface not based on dual-optical-path synchronous phase-shift interference, specifically implemented according to the following steps:

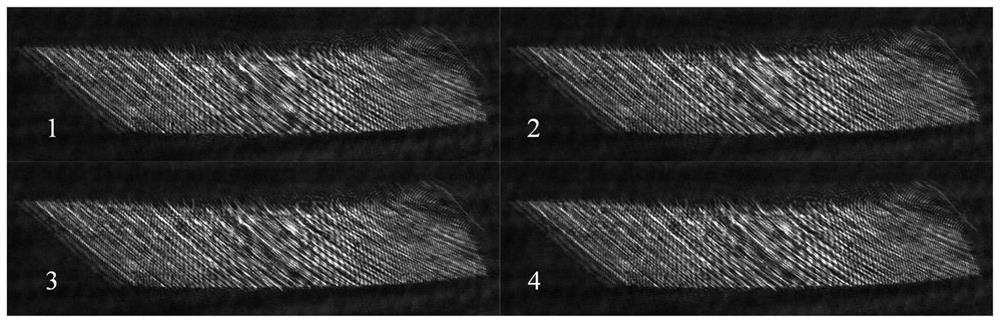

[0051] Step 1. Place the object to be measured between the front wedge 8 and the rear wedge 9 in the interferometric optical path, and adjust the interferometric optical path. When the interferometric optical path is adjusted properly, the CCD camera 18 will obtain the measured helicoid interference Striped images such as figure 2 shown;

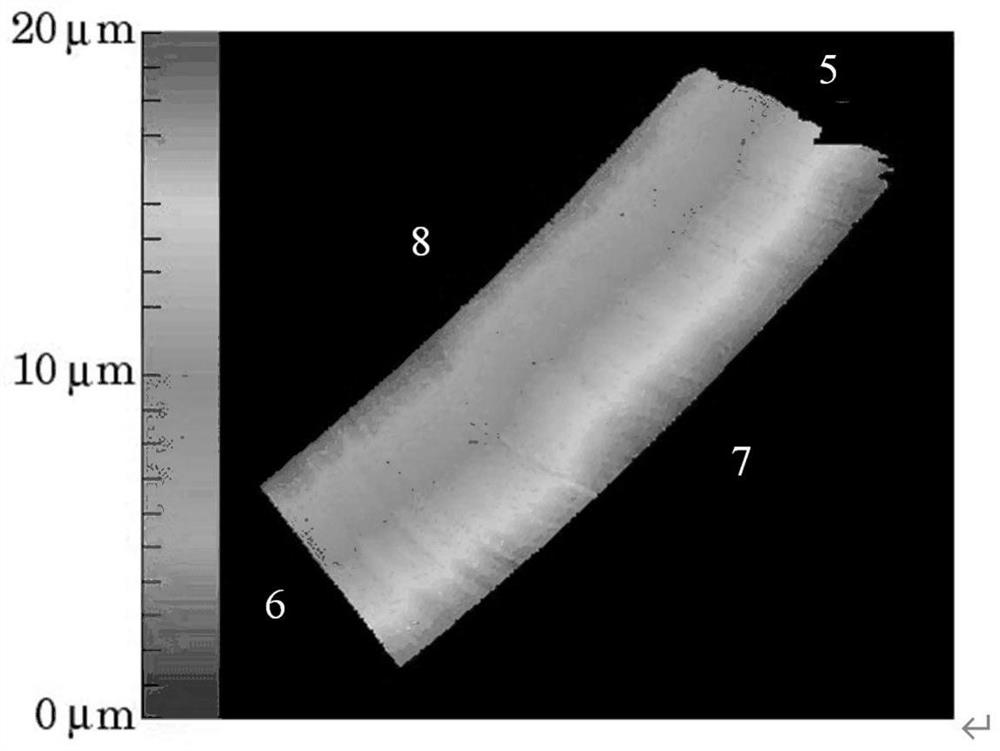

[0052]Step 2. Extract the wrapping phase of the measured helicoid according to the measured helicoid interference fringe image obtained in step 1 and the measured helicoid interference fringe image obtained in step 2 after changing the incident angle, and perform phase unwrapping. Step 2 uses phase The reciprocal variance quality map guides the unwrapping process, and the phase wrapping number k of each pixel is obtained, thereby obtaining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com