Hedge knife and hedge trimmer for spherical vegetation trimming

A technology for hedges and vegetation, applied in the field of hedge knives and hedge trimmers, can solve the problems of unfavorable belt arrangement, difficulty in belt arrangement, affecting the normal use of pruning knives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

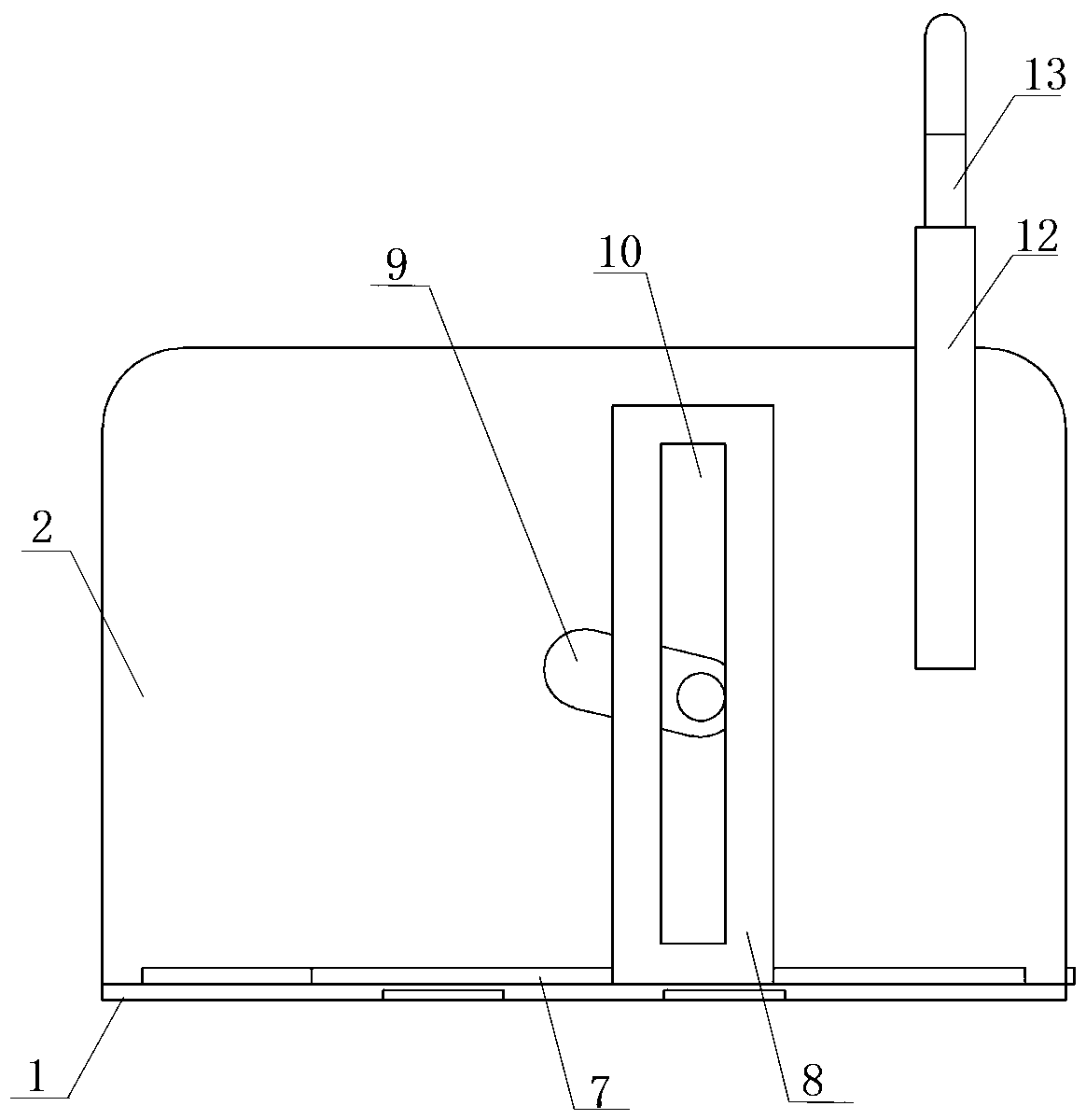

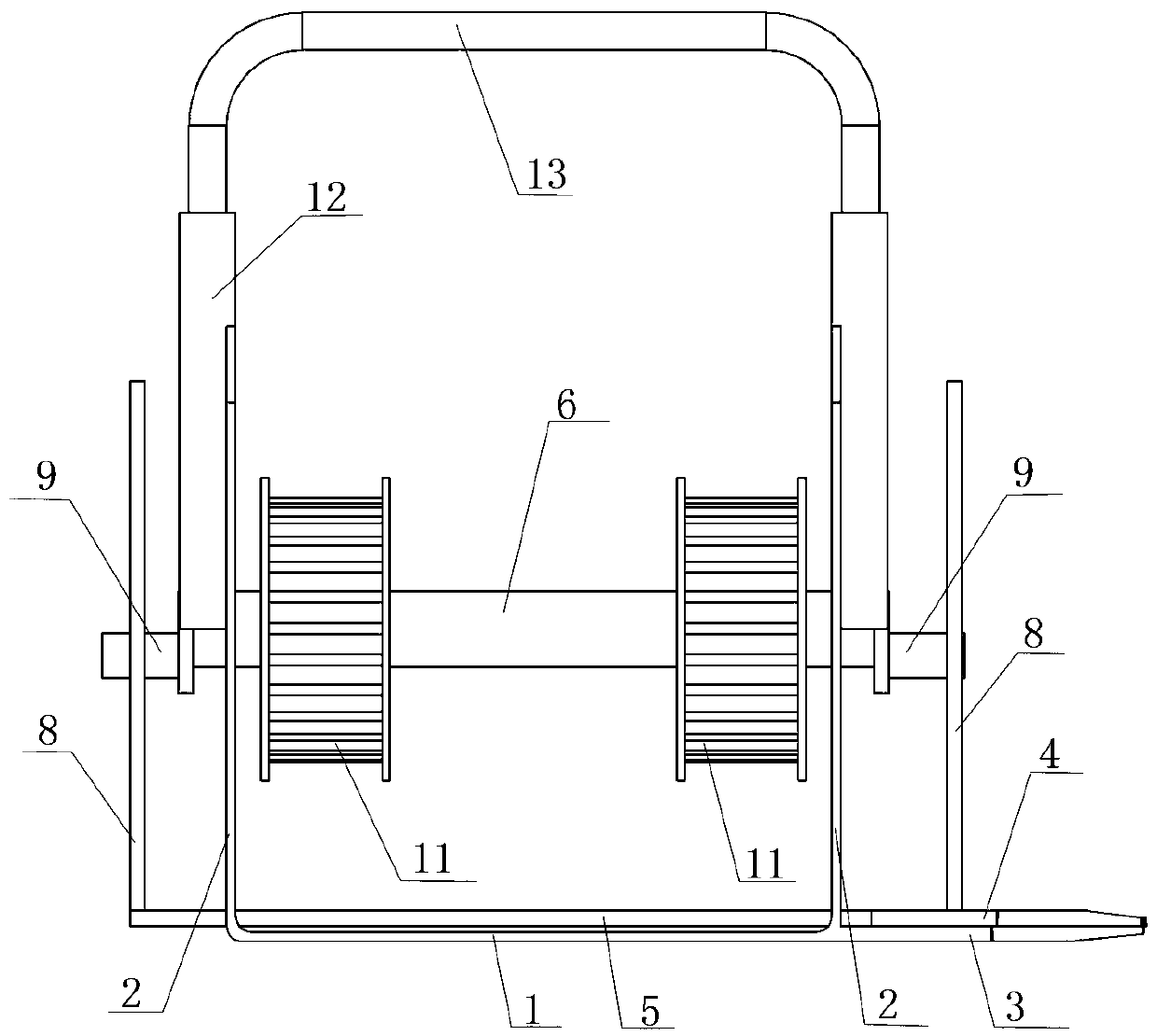

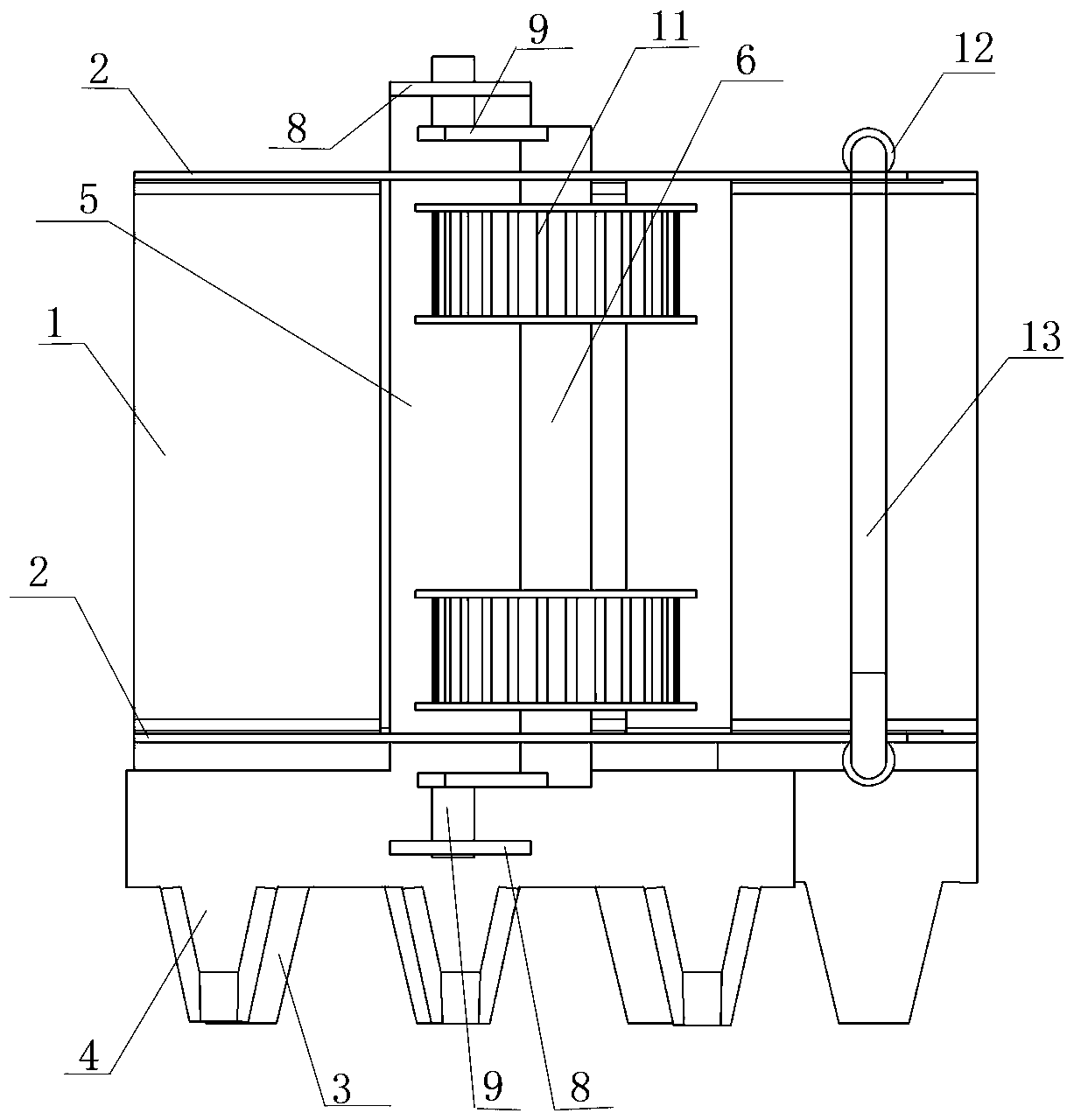

[0020] Such as Figure 1 to Figure 4 As shown, the front view, left view, top view and perspective view of the hedge knife for spherical vegetation pruning of the present invention are provided respectively. Blade 4, movable plate 5, rotating shaft 6, two guide plates 8 and two belt pulleys 11 are formed, and two side plates 2 are fixed on the both sides of base plate 1, and slot 7 is formed between side plate 2 and base plate 1. The lower serrated blade 3 is fixed on the outside of the base plate 1, the upper serrated blade 4 is positioned above the lower serrated blade 3, and the upper serrated large piece 4 and the lower serrated blade 3 are stacked together so that the upper serrated blade 4 is opposite to the lower serrated blade 3. During the reciprocating movement, the branches and leaves of the plants can be trimmed off. The two ends of movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com