An adjustable rose pruning machine

A kind of pruning machine, adjustable technology, applied in the field of adjustable rose pruning machine, to achieve the effect of reliable operation, light weight and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

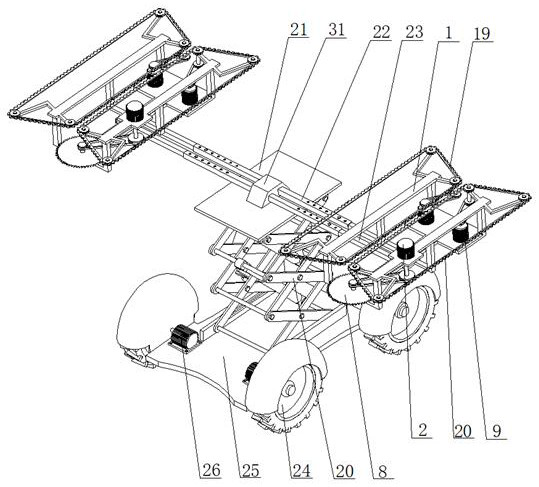

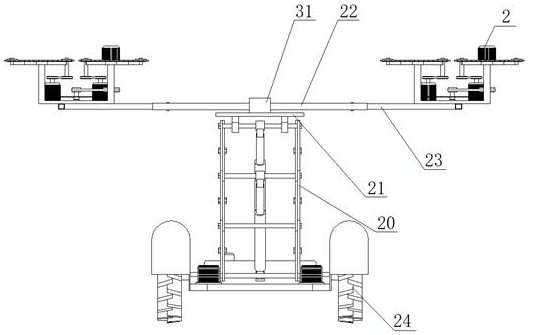

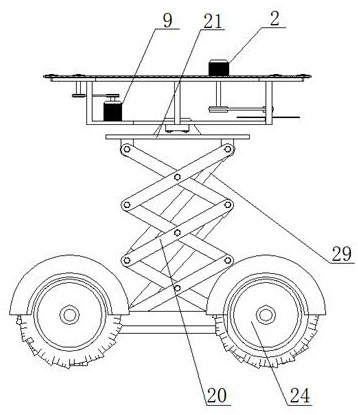

[0032] Embodiment 1: as Figure 1~9 As shown, the adjustable rose pruning machine includes a frame 25, two cutting and clustering parts, an adjusting part and a walking part;

[0033] The walking parts are installed on both sides of the frame 25, the frame 25 is provided with adjustment parts, and the two sides of the adjustment parts are respectively provided with cutting and clustering parts.

[0034] The two cutting and clustering components have the same structure, and are symmetrically installed on both sides of the adjusting component. Each of the cutting and clustering components includes a cutting support frame 1, a motor I2, a motor I spindle 3, a driving pulley I4, a driven belt Wheel Ⅰ5, transmission belt Ⅰ6, disc cutter spindle 7, disc cutter 8, motor Ⅱ9, motor Ⅱ spindle 10, driving pulley Ⅱ11, driven pulley Ⅱ12, transmission belt Ⅱ13, driven pulley Ⅱ shaft 14, pulley Ⅰ15 , pulley Ⅱ16, pulley Ⅲ17, pulley Ⅳ18, convex conveyor belt Ⅰ19, motor Ⅳ32, motor Ⅳ spindle 33...

Embodiment 2

[0041] Embodiment 2: The structure of this embodiment is the same as that of Embodiment 1, the difference is that there are 9 pin holes on the telescopic frame I22 and the telescopic frame II23 respectively, and the battery 27 is connected with two motors I2 for cutting and clustering parts through wires. It is connected with two electric motors Ⅱ 9 to supply energy for the electric motors.

[0042] The working process of this embodiment is:

[0043] When the whole machine is working, the whole machine is powered by the battery 27 for the on-board motor, and the motor III 26 drives the whole machine forward. Workers adjust the height of the lifting platform 21 and the width of the telescopic frame according to the height and ridge distance of the rose plants to be trimmed, so as to ensure reasonable The cutting position, the whole machine can trim the rose branches on the two ridges at the same time, the motor Ⅰ2 on the cutting mechanism drives the high-speed rotating disc kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com