Multifunctional hedge trimming device

A hedge trimming and multi-functional technology, applied to hedge trimming equipment, cutting tools, cutting equipment, etc., can solve the problems that landscaping plants cannot be trimmed, and arc trimming cannot be performed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

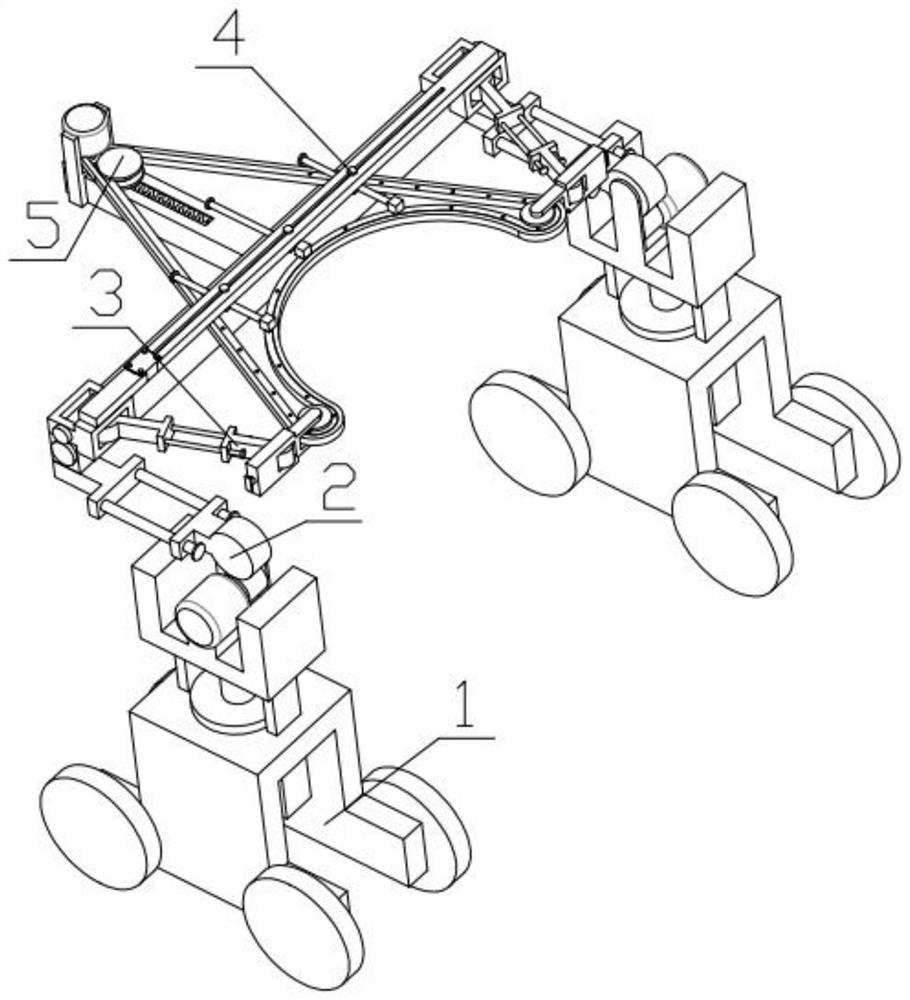

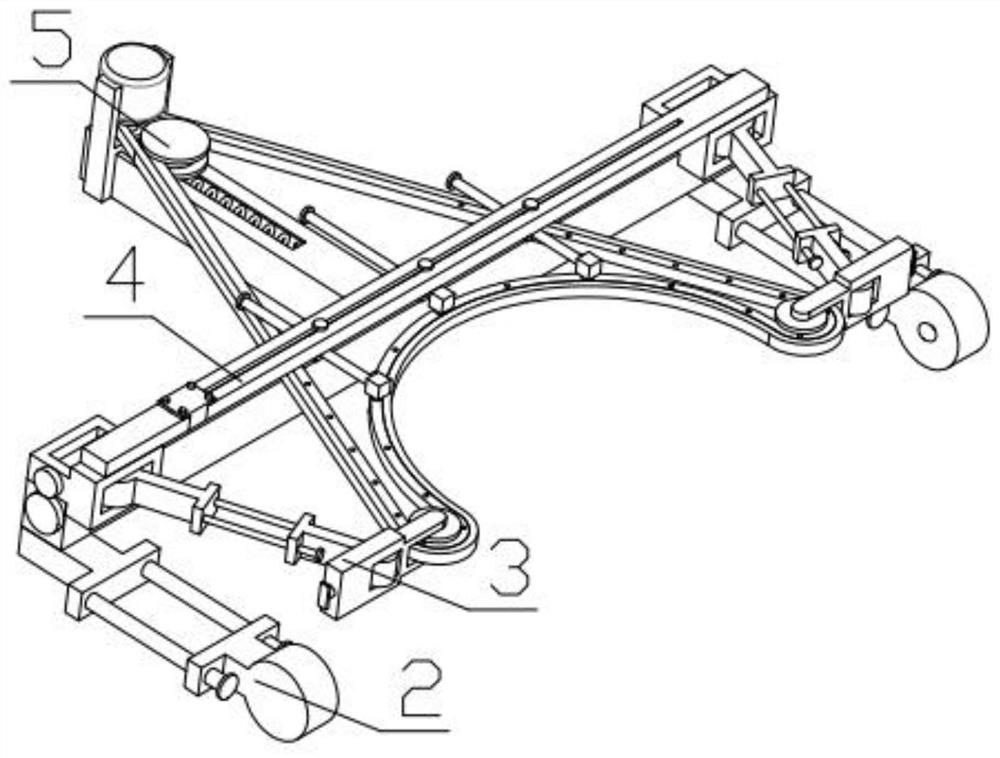

[0033] Combine below Figure 1-13Describe this embodiment, a multifunctional hedge trimming device, including a moving mechanism 1, a swing mechanism 2, a spacing adjustment mechanism 3, a shaping mechanism 4 and a chainsaw mechanism 5, the swing mechanism 2 is rotatably mounted on the moving mechanism 1, The moving mechanism 1 is meshed with the swing mechanism 2, the swing mechanism 2 is fixedly installed on the chainsaw mechanism 5, the distance adjustment mechanism 3 is fixedly installed on the chainsaw mechanism 5, the shaping mechanism 4 is fixedly installed on the distance adjustment mechanism 3, and the shaping mechanism 4 Connect with chainsaw mechanism 5.

specific Embodiment approach 2

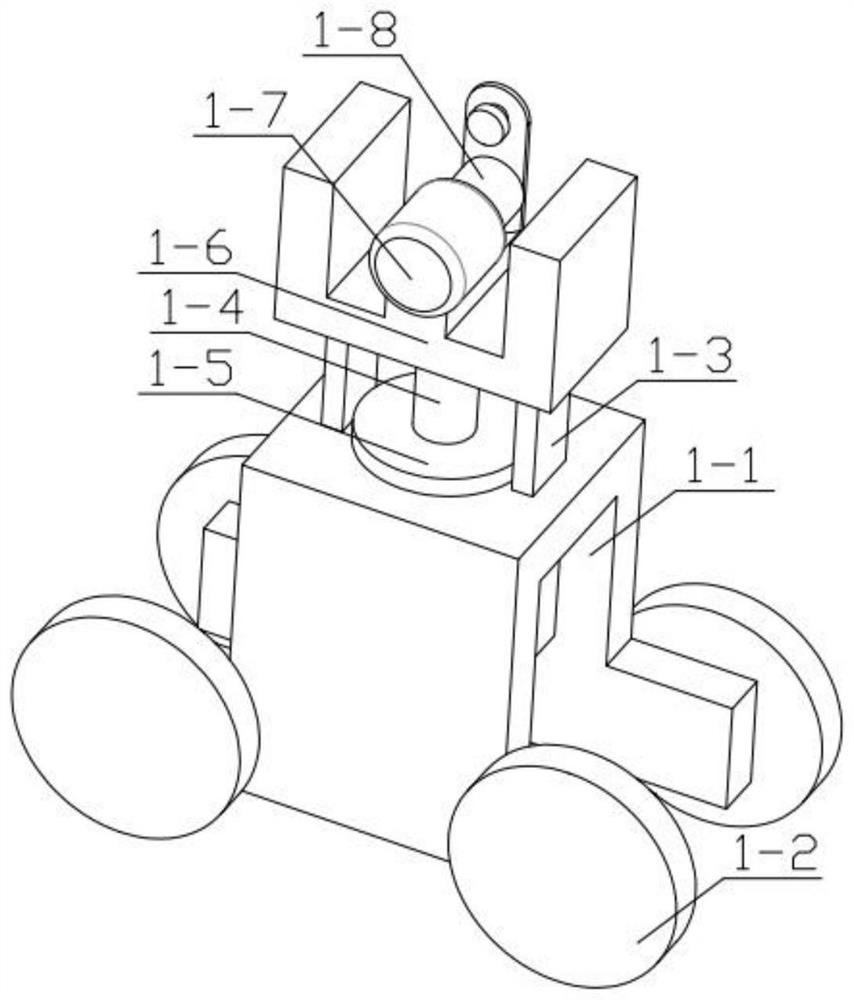

[0035] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain the first embodiment, the moving mechanism 1 includes a side frame 1-1, a moving wheel 1-2, a limit slide plate 1-3, a lifting threaded rod 1-4, an adjustment inner Threaded disc 1-5, mountain character 1-6, swing motor 1-7, motor gear 1-8, moving wheel 1-2 are fixedly installed on the side frame 1-1, and limit slide plate 1-3 is slidably installed on the side In the through hole of the frame 1-1, the groove of the side frame 1-1 is rotatably equipped with an adjusting internal thread disc 1-5, which is threadedly connected with the lifting threaded rod 1-4, and the lifting threaded rod 1 -4 is fixedly installed on the mountain character 1-6, and the limited slide plate 1-3 is fixedly installed on the mountain character 1-6, and the swing motor 1-7 is fixedly installed on the mountain character 1-6, and the swing motor 1-7 The output end of the motor gear 1-8 is fixedly installed....

specific Embodiment approach 3

[0037] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain the second embodiment, the swing mechanism 2 includes a fixed head 2-1, an adjustment threaded rod 2-2, a connecting head 2-3, a gear part 2-4, an adjustment thread The rod 2-2 is rotatably installed in the groove provided on the fixed head 2-1, and the threaded rod 2-2 is threadedly connected with the connector 2-3, and the connector 2-3 is fixedly connected with the gear part 2-4, and the gear part 2-4 is rotatably installed on the mountain part 1-6, and the motor gear 1-8 is meshed with the gear part 2-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com