Thermal forming equipment achieving servo control over furnace doors

A servo-controlled, thermoforming technology, used in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of heat loss in the heating cavity, large heat loss in the heating cavity, and increased maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

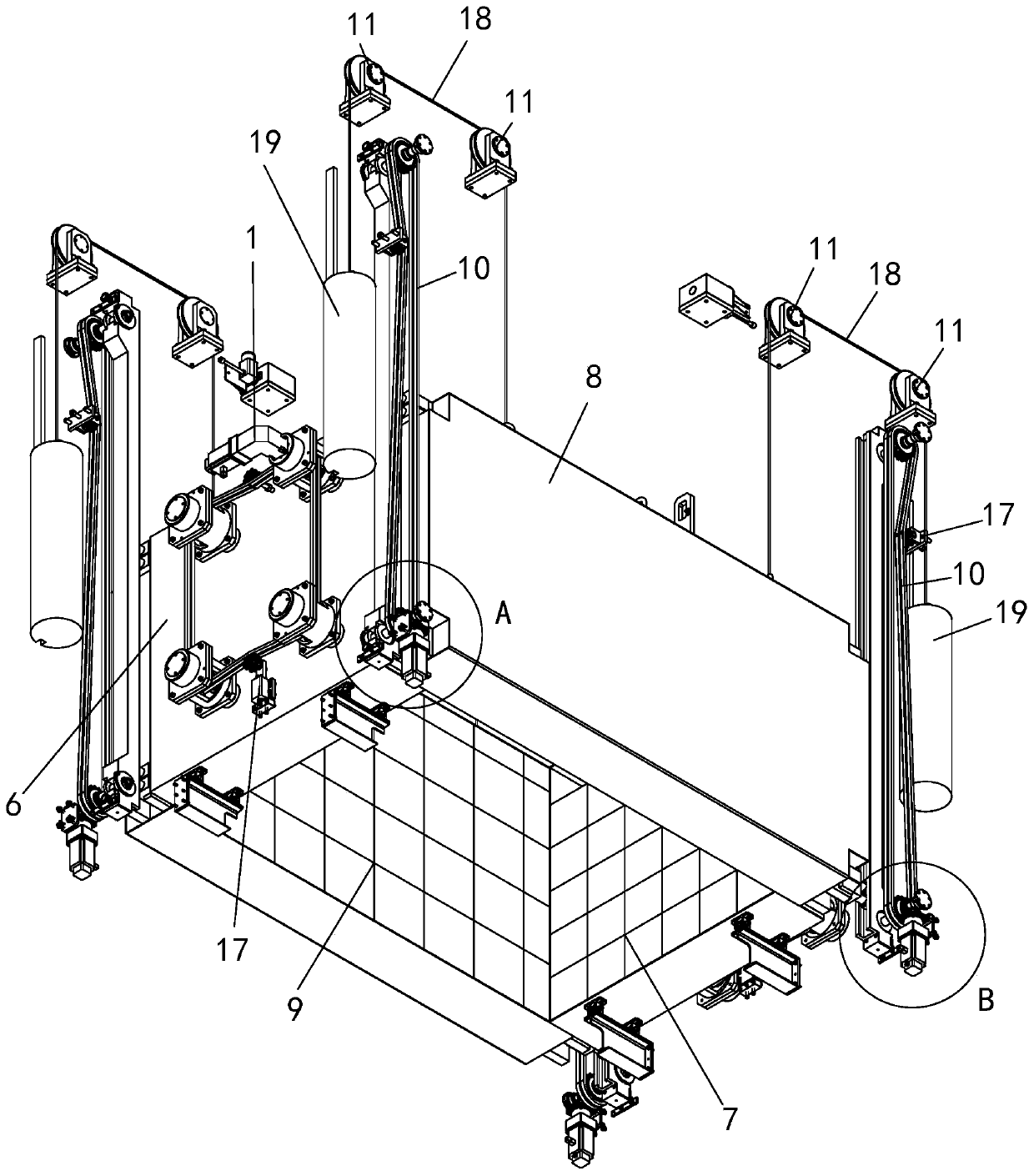

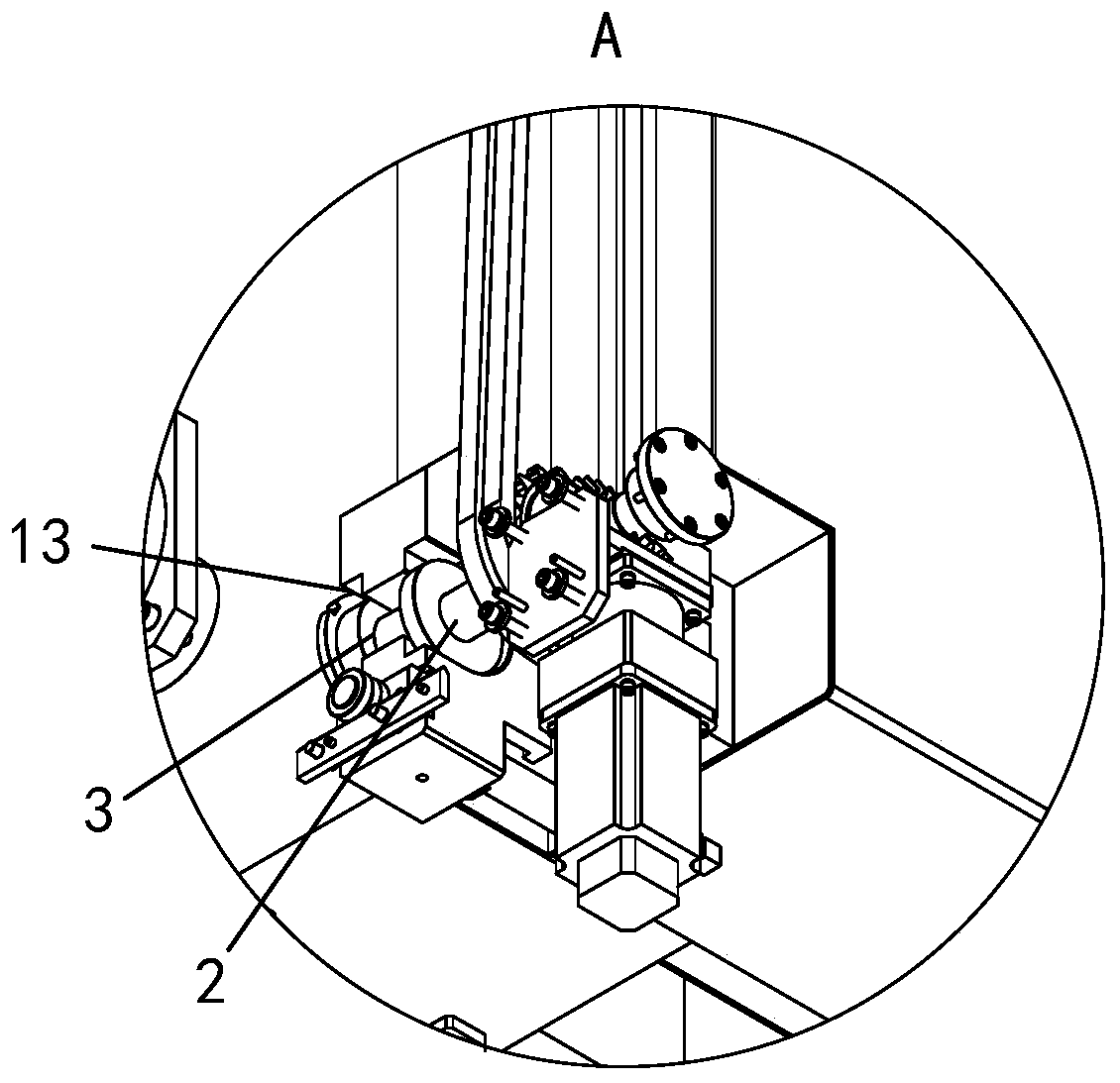

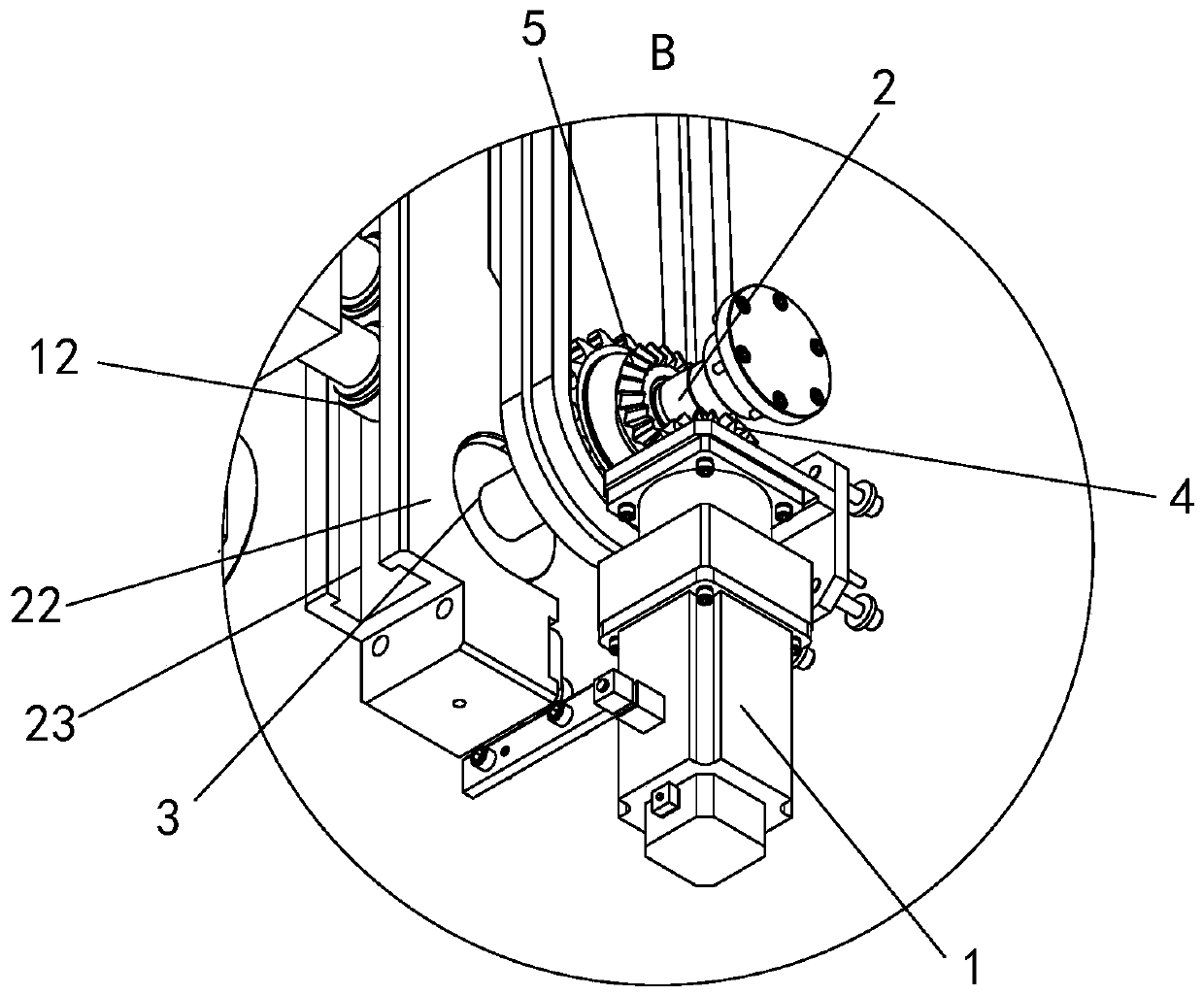

[0031] like Figure 1-7 As shown, a thermoforming equipment for servo-controlled furnace door shown in this embodiment includes a frame, a furnace door, a furnace door driving device and a heating system, and the heating system includes a heating plate (not shown in the figure).

[0032] Wherein the furnace door driving device is connected with the furnace door, and the furnace door driving device makes the furnace door movable and is arranged on the frame. The furnace door and the heating plate surround to form a heating cavity, and the heating cavity performs molding, heating and heat preservation for the parts. The furnace door moves to control the opening and closing of the heating chamber, and then pick and place parts from the heating chamber.

[0033] In this embodiment, there are two heating plates, namely an upper heating plate and a lower heating plate, the upper heating plate and the lower heating plate are arranged horizontally, the lower heating plate is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com