Modeling and control method of an automatic alignment oil change robot

An automatic alignment and control method technology, which is applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve problems such as waste of manpower, waste of manpower, and poor control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

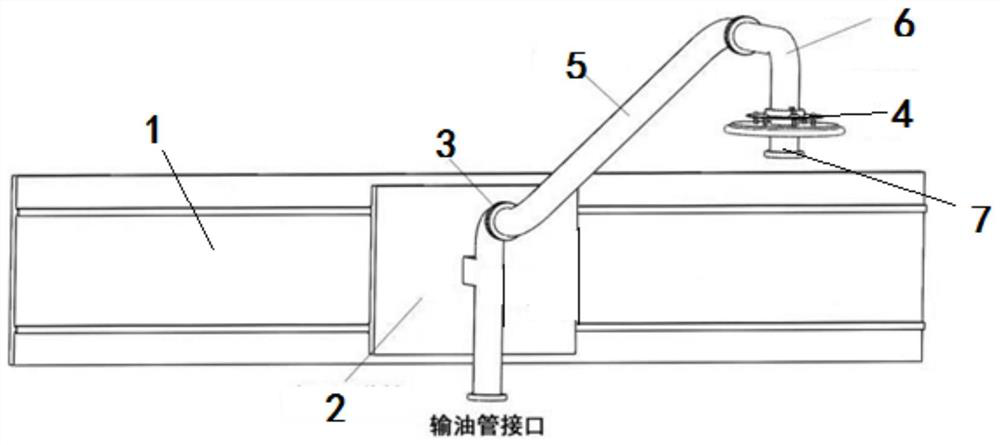

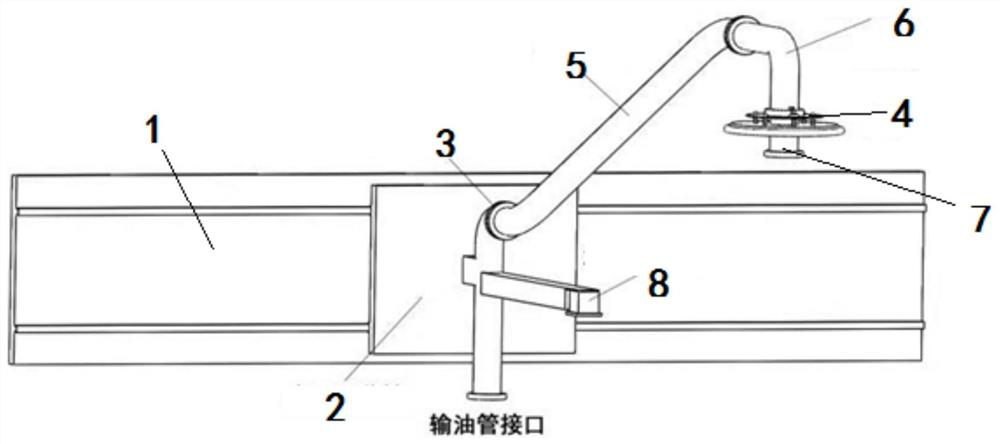

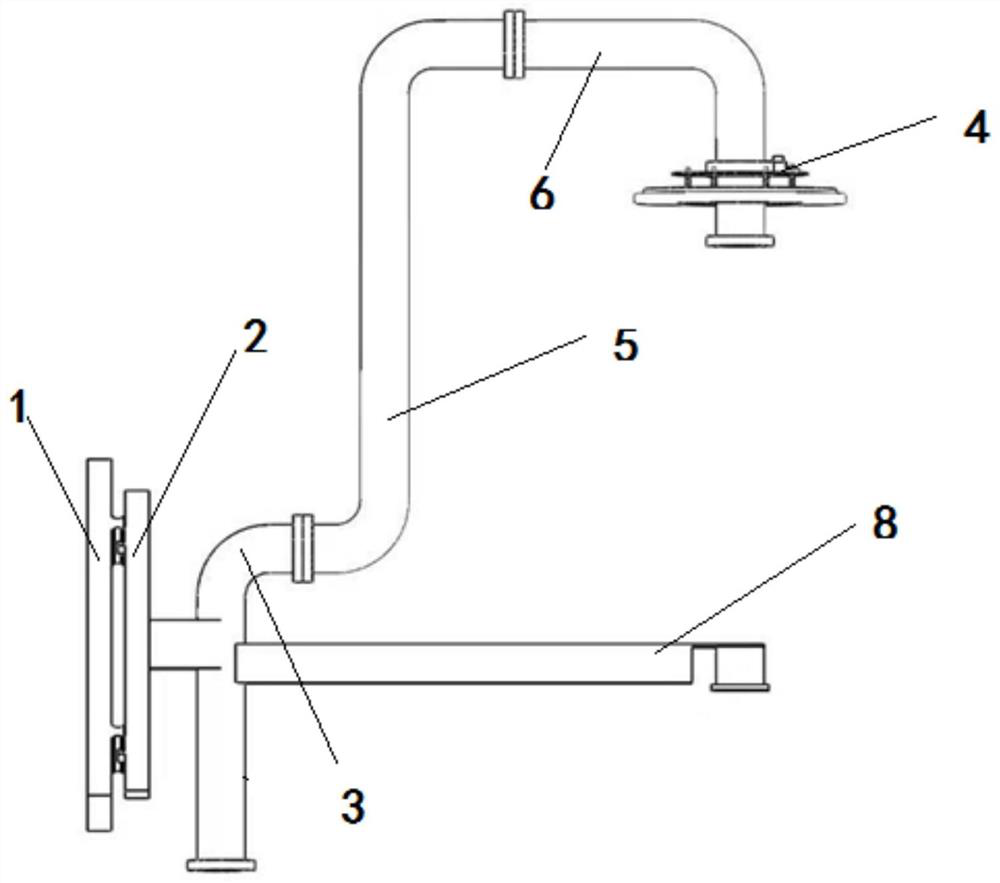

[0067] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0068] A modeling and control method for an automatic alignment oil change robot, the specific steps are as follows:

[0069] At the beginning of realizing this method, it is necessary to install a laser rangefinder 8, a proximity switch 10 and a sensor 9 on the automatic alignment oil change robot;

[0070] like figure 2 and image 3 As shown, the laser range finder 8 is installed on the horizontal translation axis 2. When the inner arm 5 of the crane tube is in a vertical state, the center point position of the laser range finder 8 is just below the center position of the oil filling port 7; Figure 5 and Image 6 As shown, the proximity switch 10 is installed under the outer arm 6 of the crane tube, and the induction piece 9 is installed on the sealing air cushion of the sealing cap;

[0071] Step [1] Modeling of automatic alignment oil change robot;

[0072]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com