Precision clamp for automatically feeding embedding part

A technology of inserting and feeding, applied in the direction of coating, etc., can solve problems such as poor working environment, easy installation problems, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0029] The object of the present invention is to provide an insert automatic feeding precision fixture installed at the end of the manipulator, so as to realize the automation of insert feeding, thereby improving production quality and efficiency.

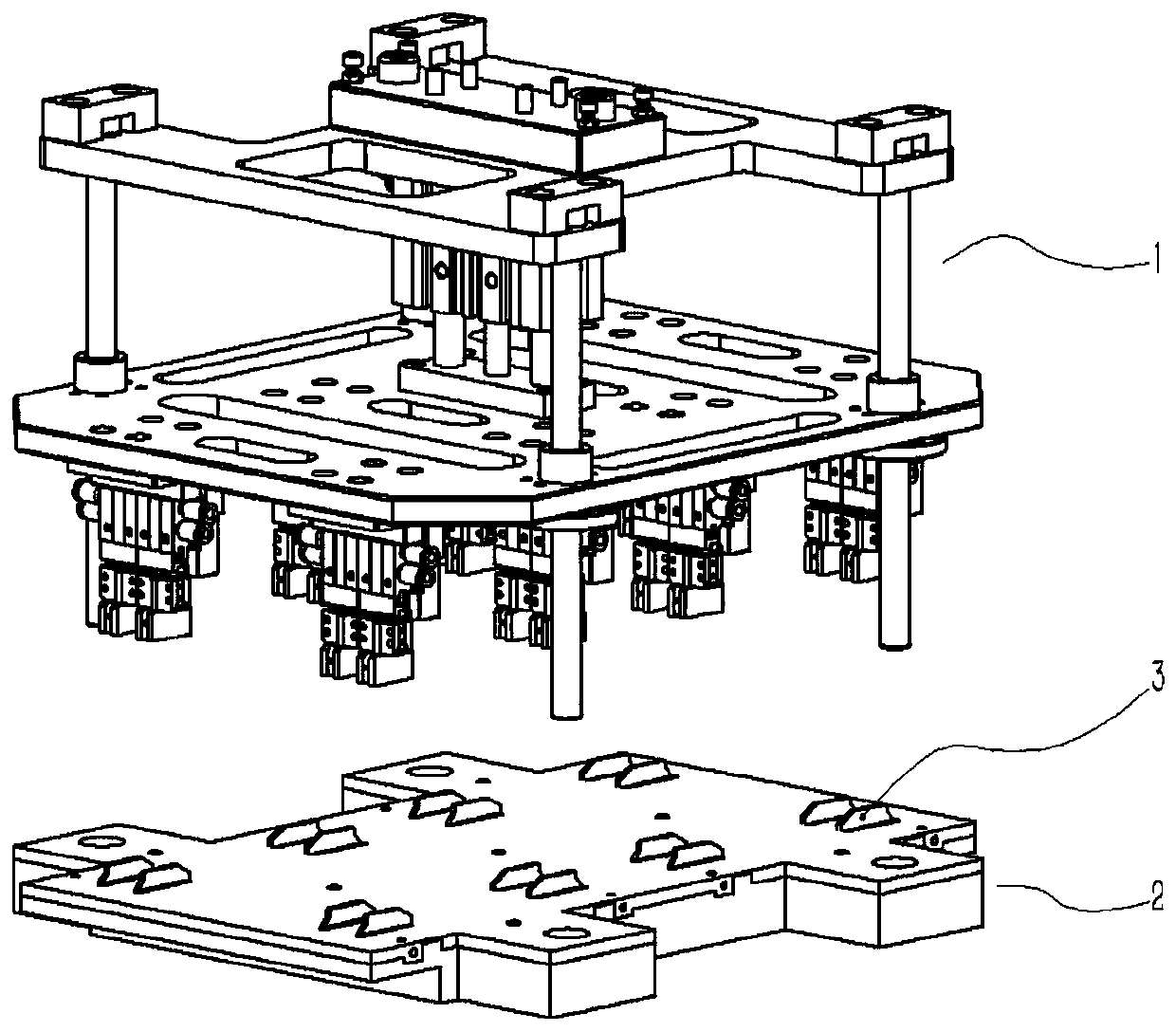

[0030] Such as figure 1 Shown is a specific embodiment of the present invention, the insert automatic feeding precision fixture of the present invention is used in conjunction with the material sorting jig.

[0031] Such as Figure 5 As shown in Fig. 1, the trimming jig is provided with insert profiling installation grooves to meet the direction and accuracy requirements of insert installation.

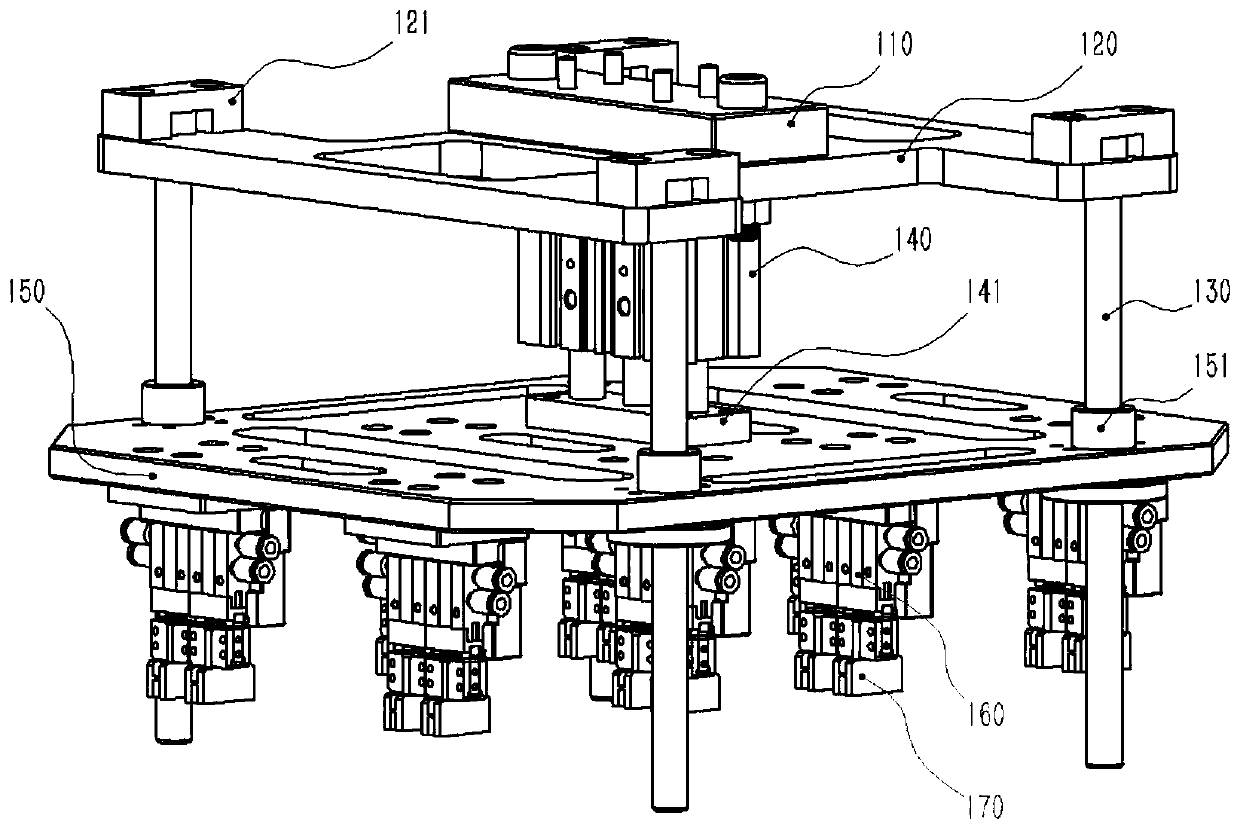

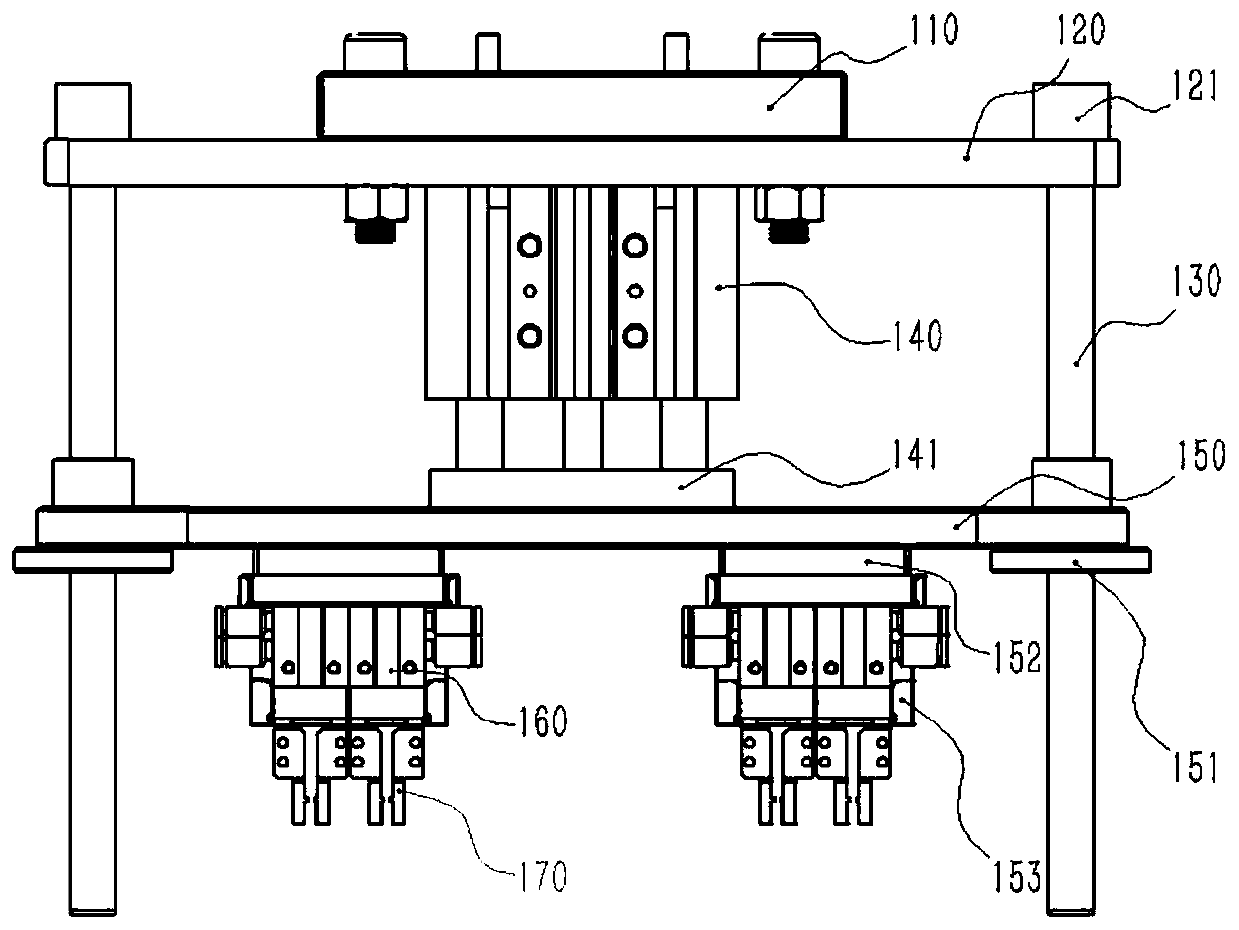

[0032] Such as figure 2 As shown, the insert automatic feeding precision fixture of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com