Injection mold

A technology of injection molds and injection molding machines, applied in the field of injection molds, can solve problems affecting manufacturing quality and low precision of workpieces, and achieve the effects of avoiding unqualified products, improving pass rate and quality, and smooth transitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

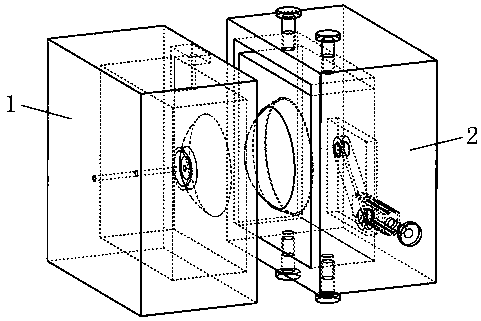

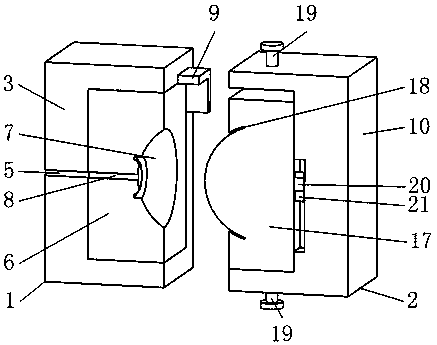

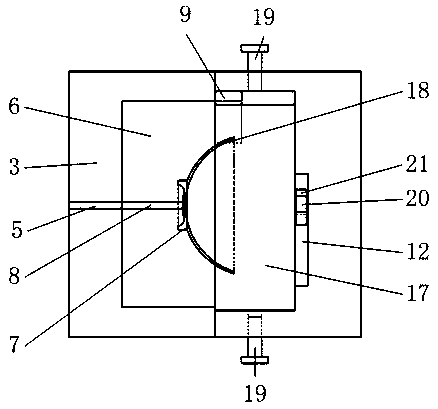

[0036] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0037] like figure 1 , 2 As shown, it includes a movable mold 2 and a fixed mold 1, wherein the fixed mold 1 is installed on the fixed mold 1 plate of the injection molding machine, and the movable mold 2 is installed on the movable mold 2 plate of the injection molding machine to cooperate with the fixed mold 1. Complete injection molding.

[0038] like image 3 , 4 As shown, the above-mentioned movable mold 2 includes a movable mold base 10, a movable mold core 17, a fastening bolt 19, a second hinge pin 20, a push plate 21, a first hinge pin 22, a slider 23, an adjusting screw 24, and a knob 25, Among them such as Figure 9 As shown, there is a second positioning groove 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap