Separated air outlet blade clamping structure

A separate air outlet technology, which is applied in the field of clip joint structure of separate air outlet blades, can solve the problems of loose matching of upper and lower separated blades and difficult assembly of upper blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, three horizontal rib structures and six longitudinal rib structures are adopted, which are evenly arranged on the lower blade, and one insert and bayonet are provided.

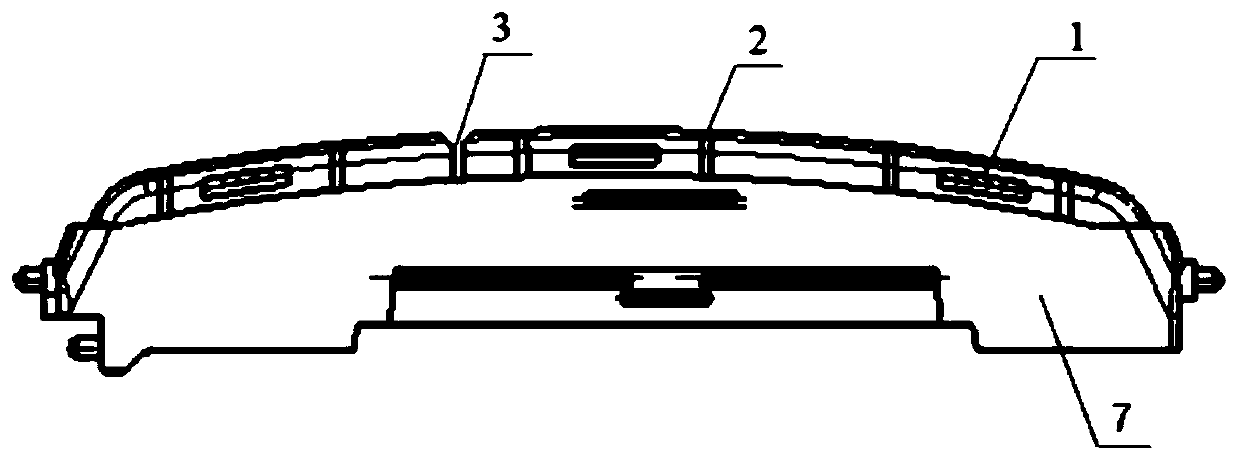

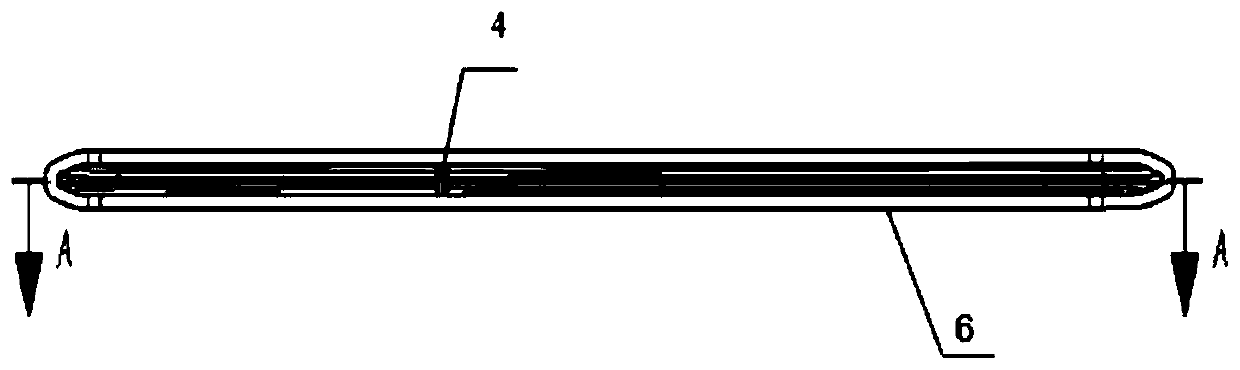

[0029] A split air outlet vane clamping structure, such as figure 1 As shown, the detached blade clamping structure of the air outlet in this embodiment includes three structural features: three transverse ribs 1, six longitudinal ribs 2 and one installation guide and positioning structure 3. The installation guide and positioning structure consists of figure 1 Medium mount 3 and figure 2 Middle insert sheet 4 constitutes.

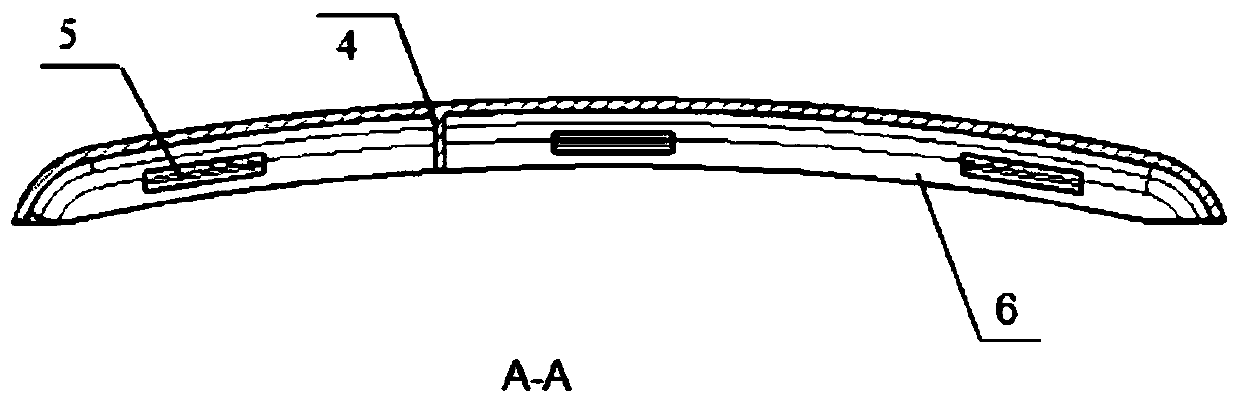

[0030] Such as figure 1 As shown, the transverse rib 1 is evenly distributed on the lower blade 7 in three places, as Figure 6 The transverse rib shown is a semicircular raised strip rib with a radius of 0.8 mm, which is the same as image 3 The structure of the groove 5 corresponding to the middle and upper blade 6 forms a reliable clamping structure, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com