Computer case dustproof device

A dust-proof device, computer technology, applied in the direction of calculation, separation methods, instruments, etc., can solve the problems of inability to adjust the filtration accuracy, inability to trade off the ventilation of the chassis and dust-proof performance, and insufficient applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

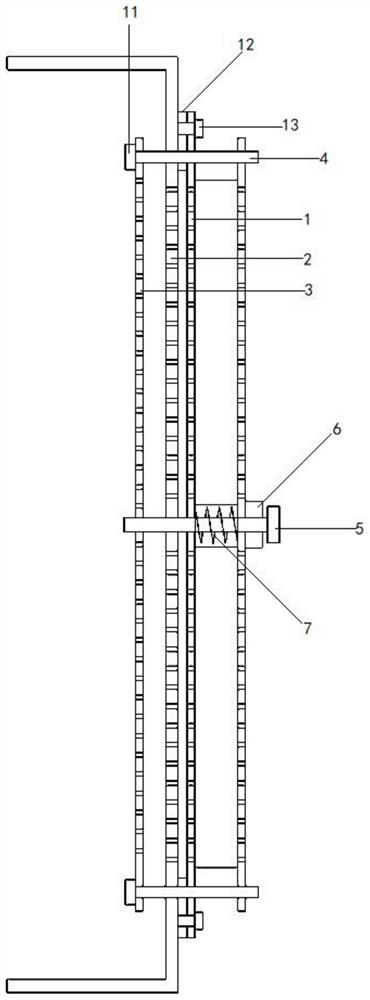

Embodiment 1

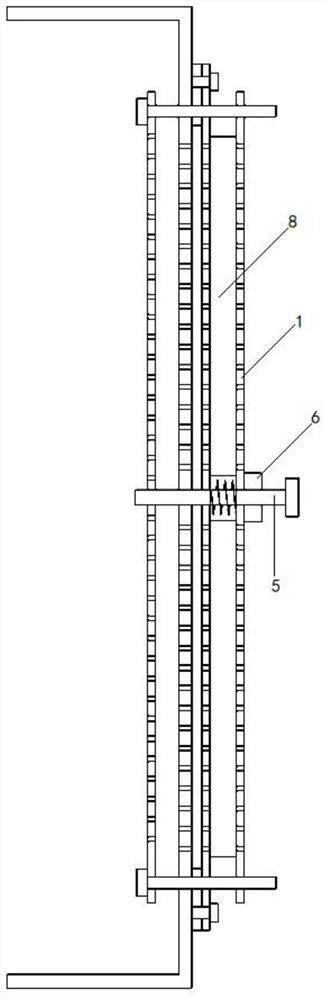

[0032] In this embodiment, the adjustable filter layer adopts the sponge layer 8. The sponge layer 8 is a porous structure. After being compressed, the pore diameter of the internal pores will be reduced, thereby improving the filtering accuracy of dust. When the filtration accuracy needs to be improved, the adjusting nut 6 is screwed, and the support net 1 on the front side is pushed back, such as figure 2 As shown, the spring 7 is compressed, and the sponge layer 8 can be compressed; when the filtration accuracy needs to be reduced, the adjusting nut 6 is reversely screwed, and the support net 1 on the front side is pushed forward by the elastic force of the spring 7, and the Due to the elastic force of the sponge layer 8 itself, the sponge layer 8 can be gradually released from the compressed state.

[0033] When cleaning, press the two support nets 1 to compress the sponge layer 8, and then release the elastic force of the spring 7 to not only restore the sponge layer 8 f...

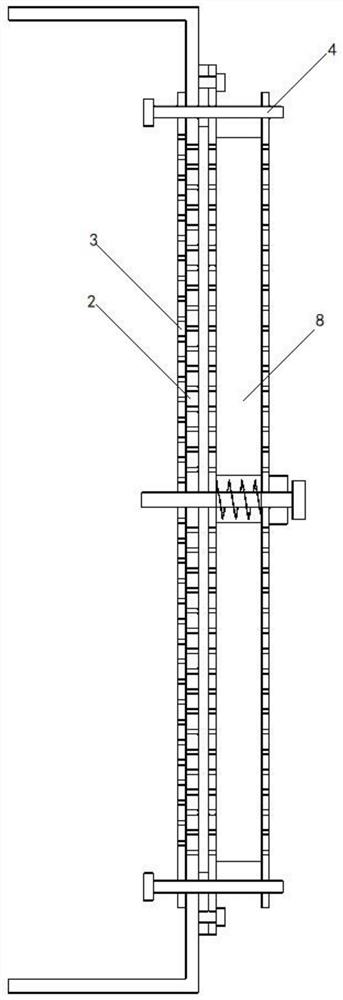

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is that the adjustable filter layer adopts the PP melt-blown layer 9 .

[0036] The PP melt-blown layer 9 is also a porous structure. The dust filtration accuracy can be adjusted by compressing and releasing the PP melt-blown layer 9. However, the sponge layer 8 has strong elasticity and can recover by itself when released, so it does not need to be connected with the support. The net 1 is fixed, but the elasticity of the PP melt blown layer 9 is not strong, and it is difficult to recover through its own elasticity when it is released. Therefore, the PP melt blown layer 9 and the support net 1 need to be fixed, and the PP melt blown layer 9 is driven by the support net 1 when released. Resume from a compressed state.

[0037]For this reason, on the inner surface of the support net 1, the hook surface mesh adhesive chain 10 is attached and fixed, and the hook surface shape of the hook surface mesh adhesive chain 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com