Anti-falling elevator

A technology for anti-falling and elevators, which is applied to elevators, elevators, transportation and packaging in buildings, etc. It can solve problems such as difficult operation and wear of steel ropes, aging and deformation of steel ropes, missed detection and wrong detection of steel ropes, etc., and achieves The effect of avoiding serious casualties, preventing severe falls, and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

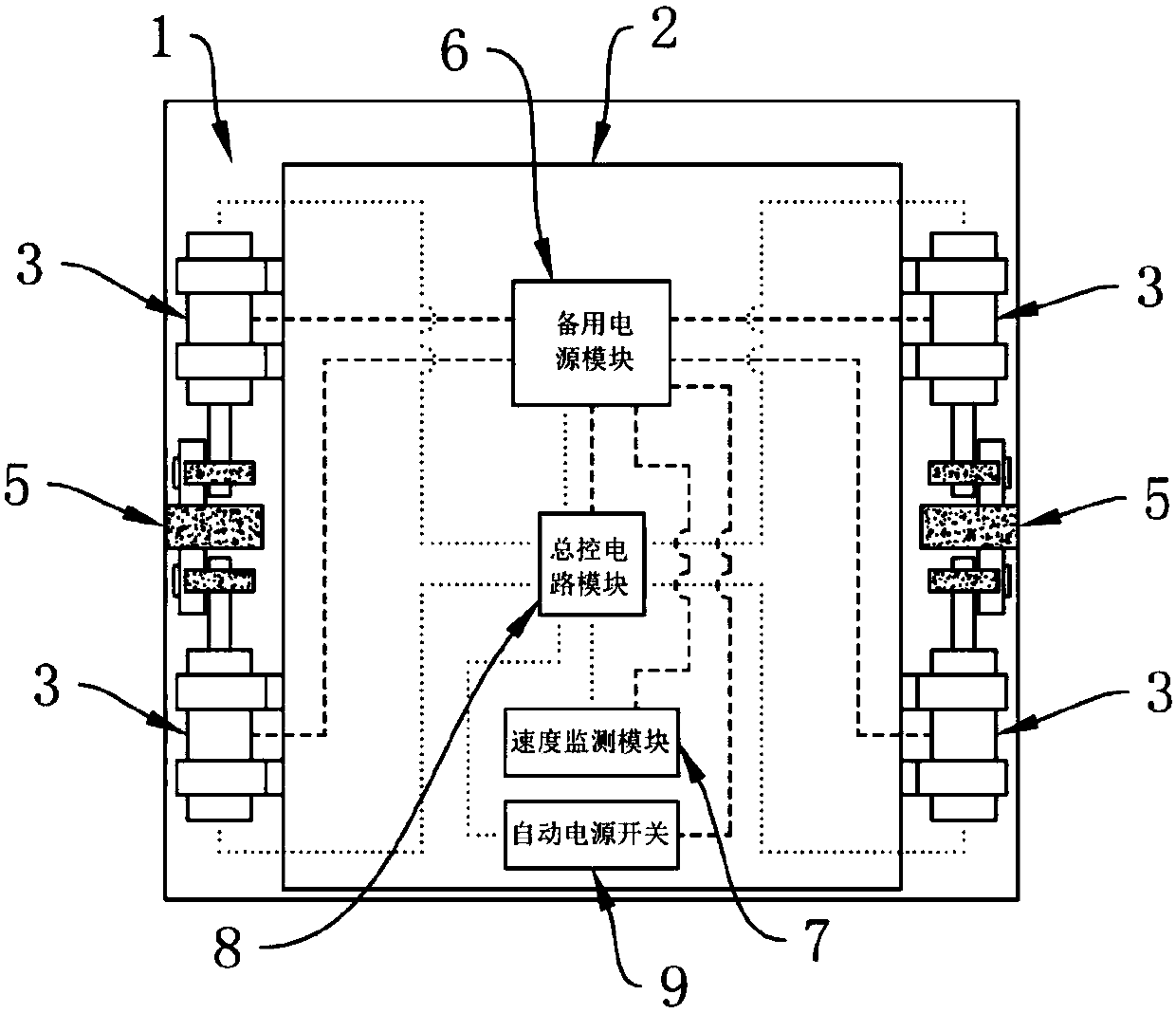

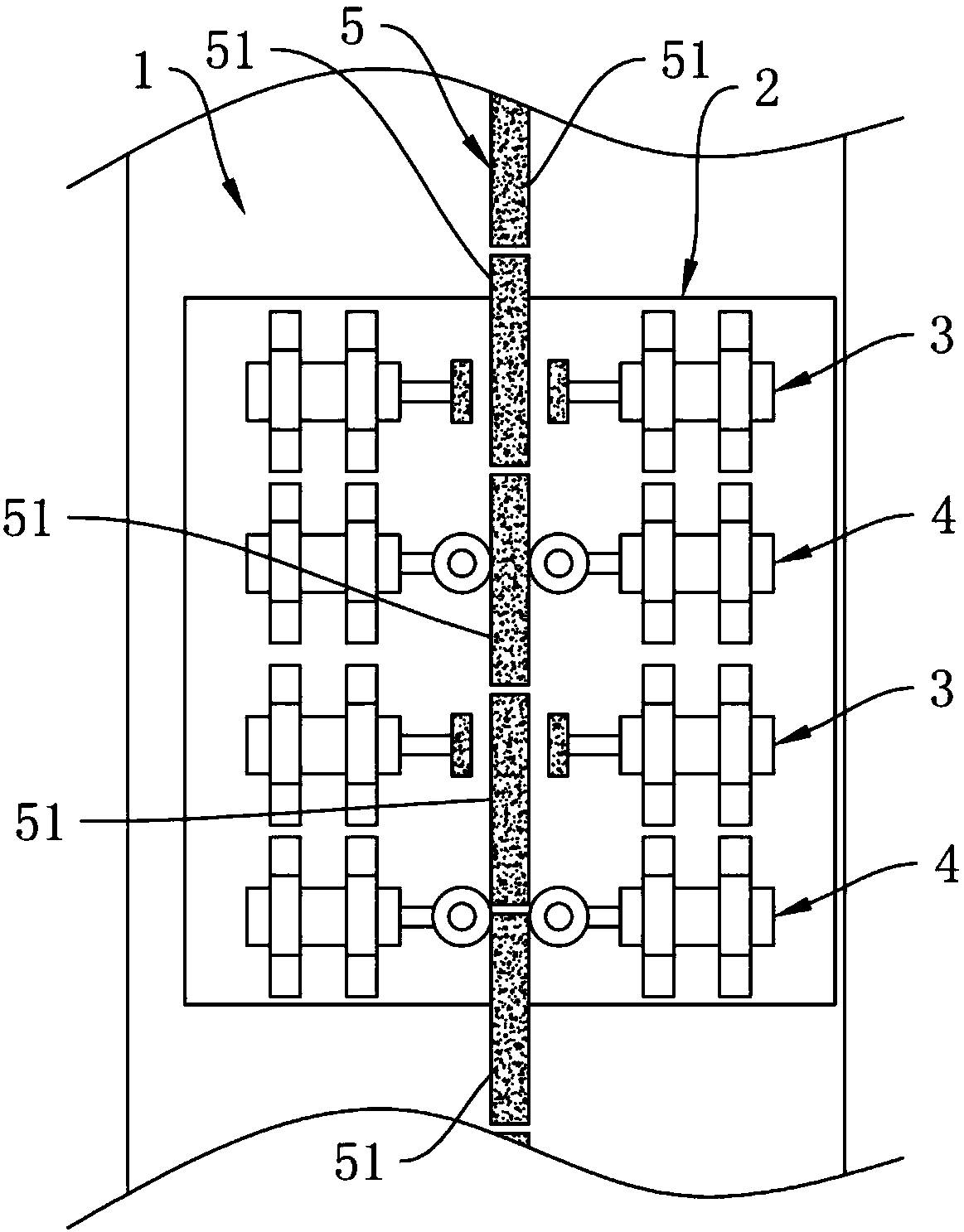

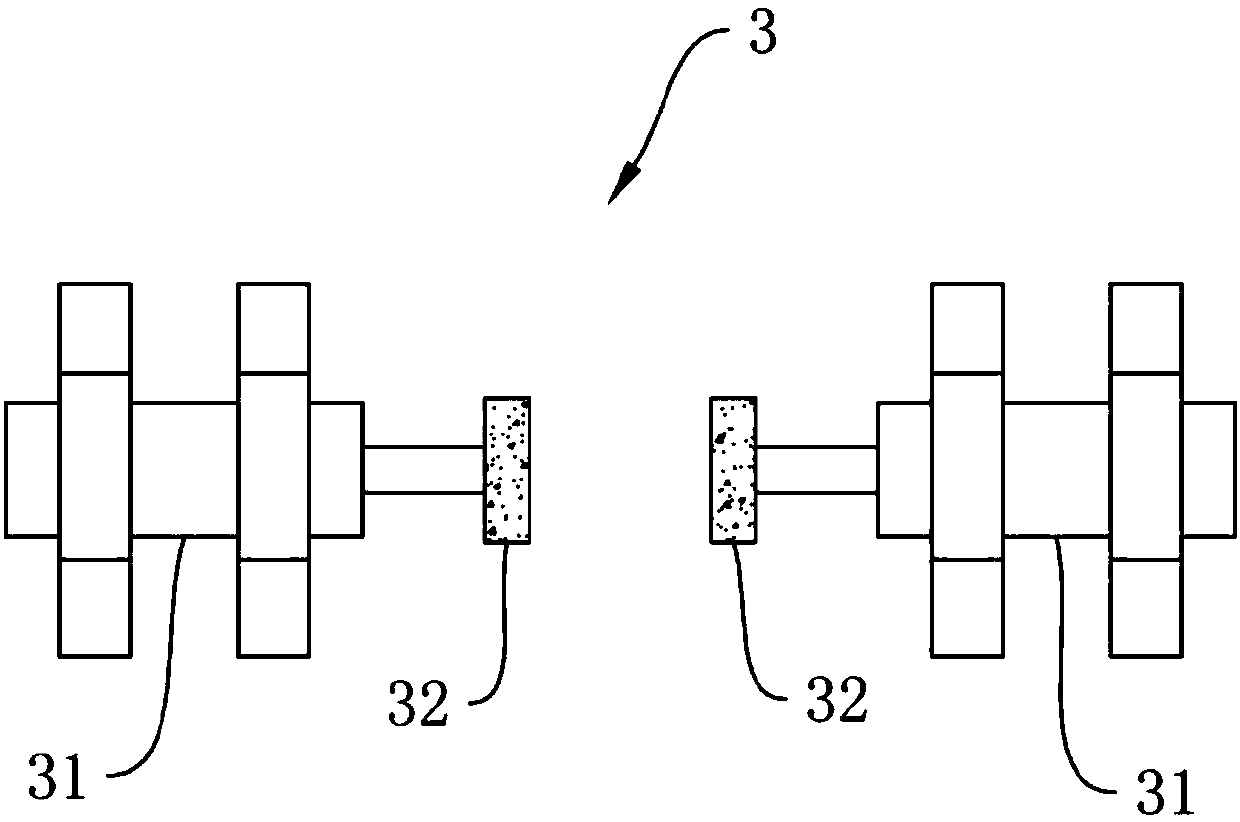

[0014] Such as figure 1 and figure 2 As shown, a kind of anti-falling elevator of the present invention comprises elevator shaft 1, elevator car 2, and described elevator car 2 can be vertically and movablely arranged in elevator shaft 1, in order to realize the purpose of the present invention, includes A number of friction positioning mechanisms 3, a number of flexible limit mechanisms 4, two friction guide rails 5, a backup power supply module 6, a speed monitoring module 7, a master control circuit module 8, and an automatic power switch 9, wherein, such as image 3 As shown, the friction positioning mechanism 3 includes two driving cylinders 31 and two positioning friction heads 32. On the outer end of the piston rod; if Figure 4 As shown, the flexible limit mechanism 4 includes two elastic contact assemblies 41, the elastic contact assembly 41 includes a contact wheel 411, a limit cylinder 412, a movable rod 413, and a spring 414, and one end of the movable rod 413 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com