Stainless steel surface microtexture processing method and preparation device based on ultrasonic peening

An ultrasonic impact and preparation device technology, applied in the field of material processing, can solve the problems of difficult to accurately control the texture geometry, affect the physical and mechanical properties of the texture, and the precision of precision machining is not high, so as to avoid the generation and deformation of chips and dust Small size, high processing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

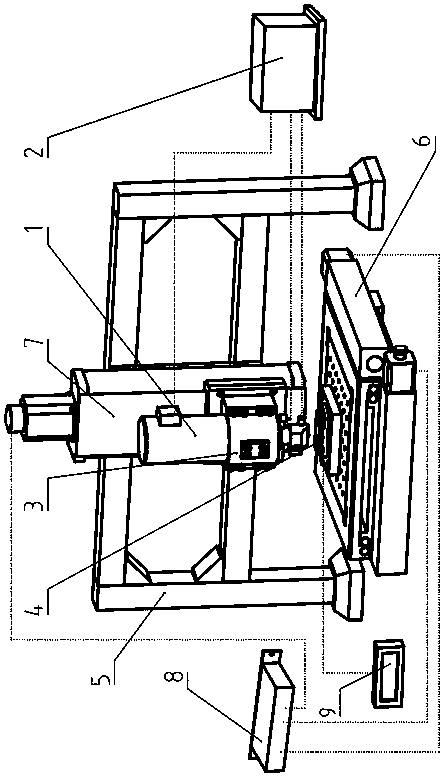

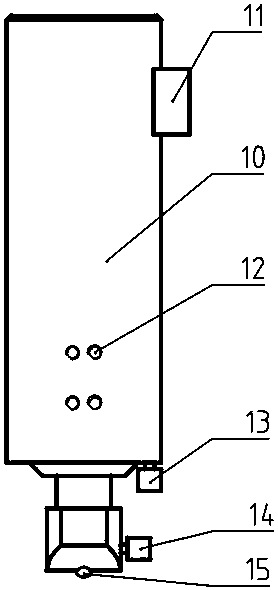

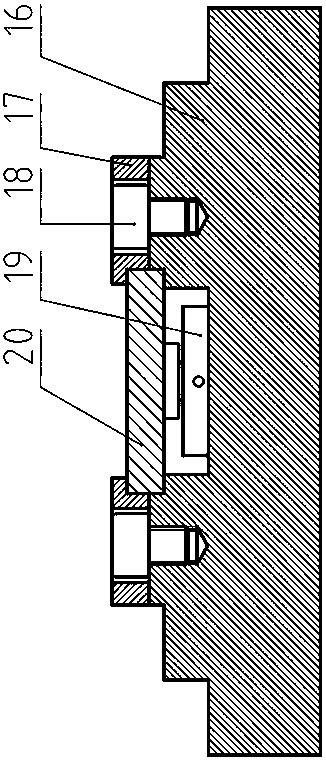

[0034] Such as Figure 1~3 As shown, the stainless steel surface micro-texture preparation device based on ultrasonic impact provided by the present invention includes an ultrasonic impact gun 1, an ultrasonic impact gun control cabinet 2, a special clamp for the ultrasonic impact gun 3, a special clamp for stainless steel workpieces 4, a marble gantry 5, and an XY Axis overall motion platform 6, Z-axis motion platform 7, three-axis motion controller 8, pressure display 9. in:

[0035] The ultrasonic impact gun 1 is screwed to the special clamp 3 for ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap