Ultrasonic-assisted radial gear rolling forming device

An ultrasonic-assisted, gear technology, applied in the direction of gears, household appliances, other household appliances, etc., can solve the problems of large deformation force, long processing time, low tooth surface strength, etc., and achieves low friction, improved processing efficiency, rolling wheel The effect of increasing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to express the above-mentioned purpose, features and advantages of the present invention more clearly, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

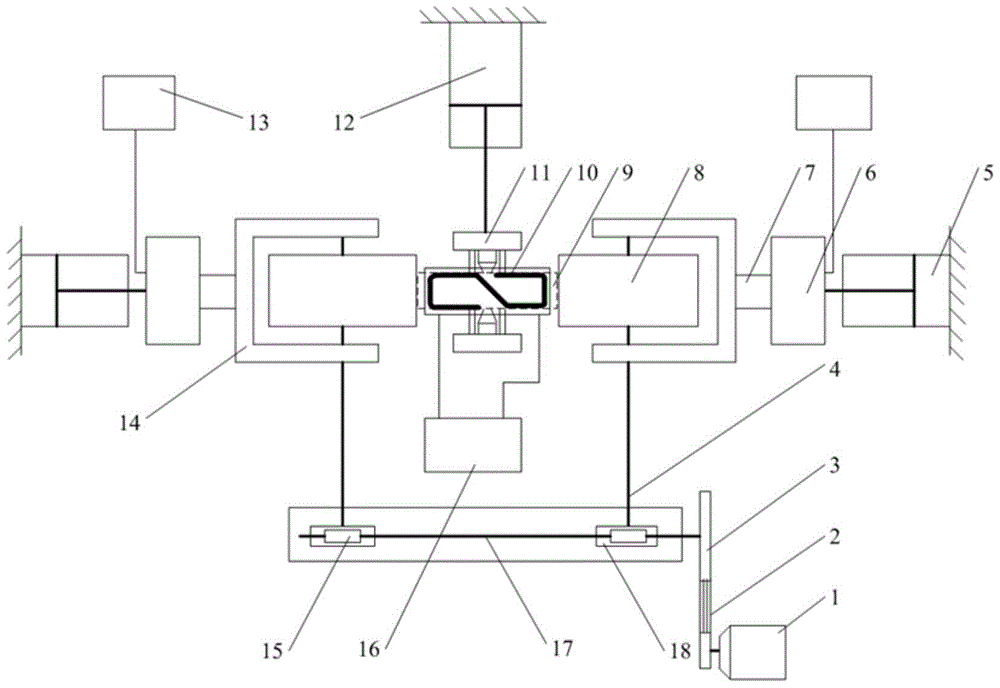

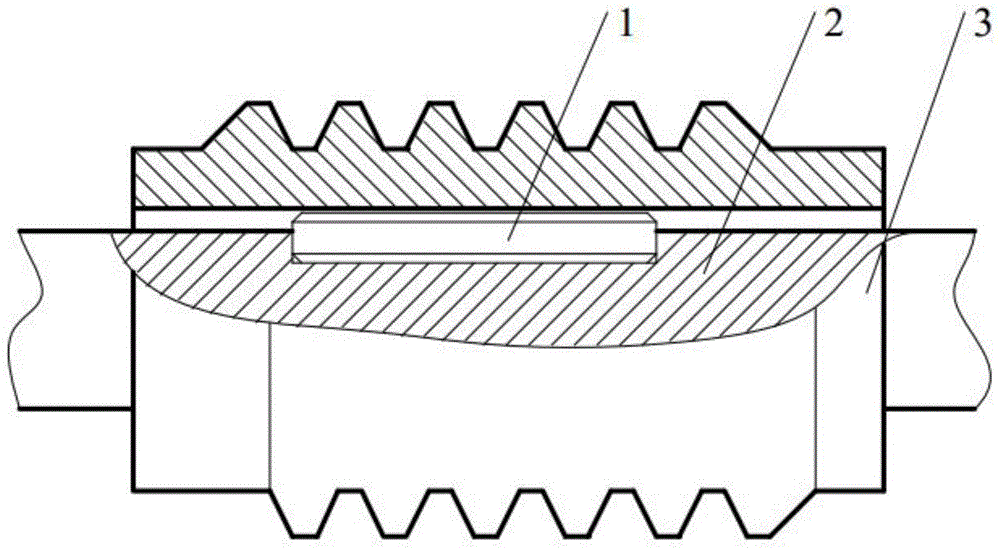

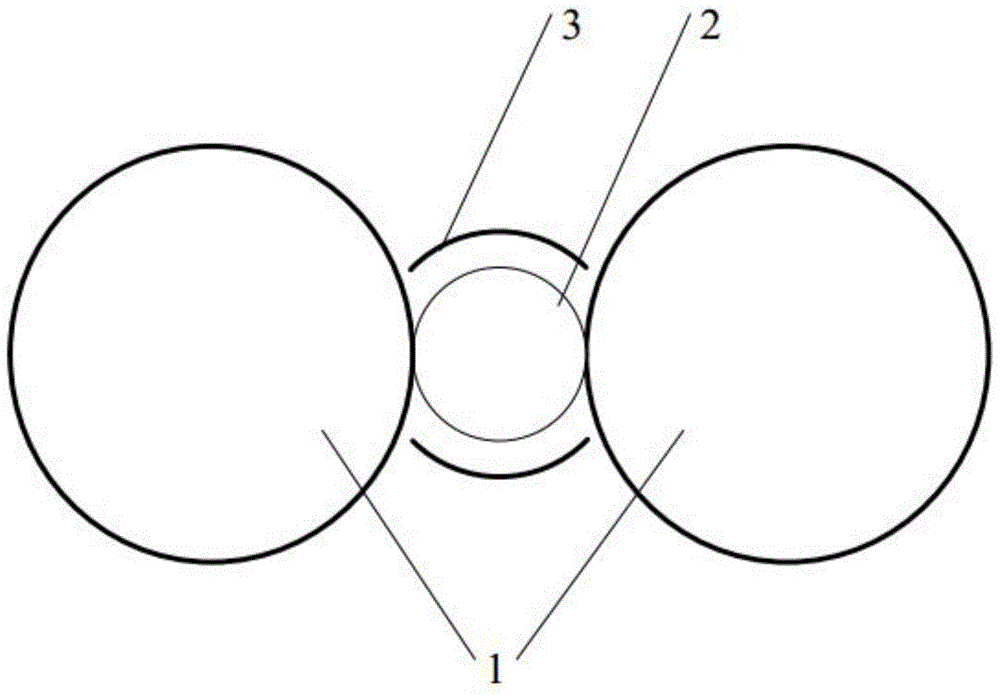

[0022] The ultrasonic auxiliary gear radial rolling forming device proposed by the present invention is as follows: figure 1 As shown, it is mainly composed of power and transmission system, radial feeding system, feeding system, induction heating system and ultrasonic vibration system. The power and transmission system mainly includes a motor 1 , a belt 2 , a pulley 3 , a drive shaft 4 , a worm 15 , a driving shaft 17 and a worm wheel 18 . The motor 1 drives the pulley 3 to rotate through the belt 2, and then the driving shaft 17 drives the worm 15 and the worm wheel 18 to rotate, and then drives the rolling wheel 8 on the transmission shaft 4 to realize the rolling process. When rolling wheel 8 needs radial feed, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com