Insulating engineering ceramic discharging and milling servo device

A technology of insulation engineering and servo devices, applied in the field of mechanical processing, can solve the problems of low processing efficiency, achieve high processing efficiency, small macroscopic force, and avoid environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

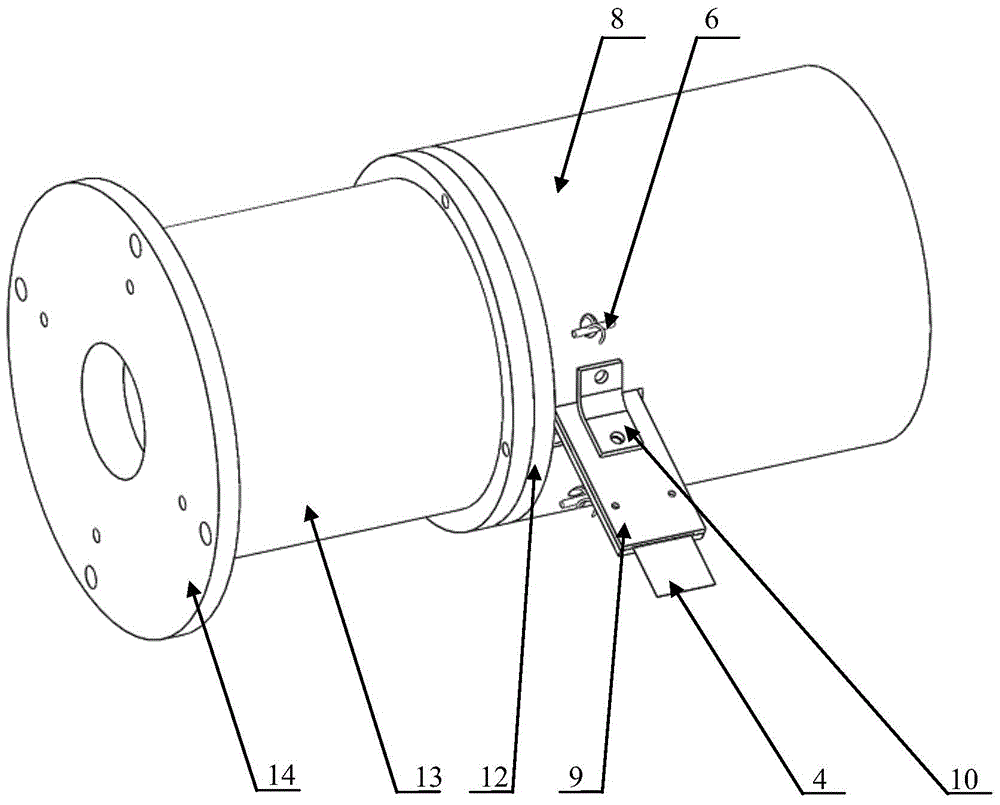

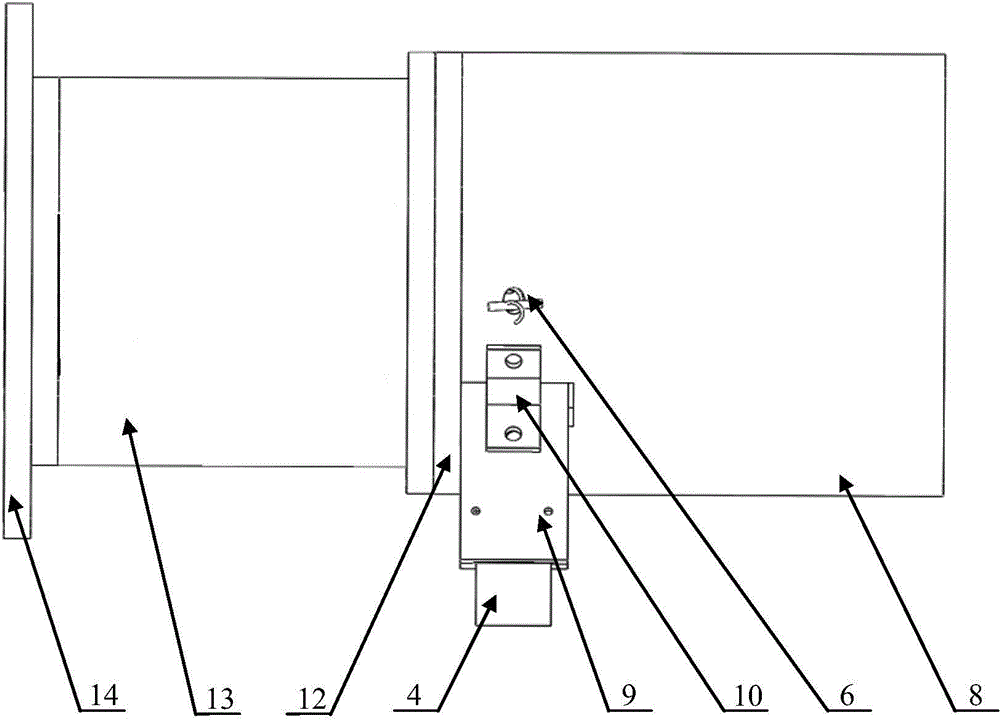

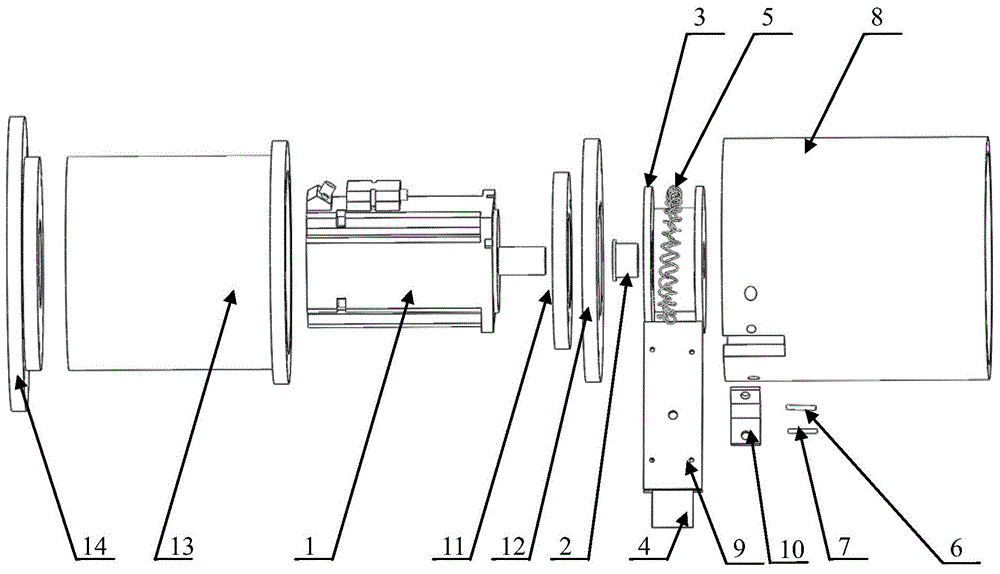

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the insulating engineering ceramic discharge milling servo device mainly includes: servo motor 1, storage wheel 3, spring 5, outer cylinder 8, guide plate 9; where:

[0024] The servo motor 1 is an AC servo motor, the positioning shaft of the servo motor 1 is installed in the inner hole of the flange 11, and the two maintain an interference fit, so that the servo motor 1 is tightly installed in the flange 11; the flange 11 Connect the outer cylinder cover 12 by bolts; one end of the motor housing 13 is connected to the outer cylinder cover 12 by bolts, and the other end is connected to the motor housing cover 14 by bolts, so that the servo motor 1 is located in the motor housing 13 to protect the servo motor 1 , The motor housing cover 14 is fixed on the machine tool through bolt connection.

[0025] The outer cylinder 8 is a cylindrical shell, the outer cylinder 8 is connected with the outer cylinder cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com