Servomechanism for milling electric spark made of non-conducting material

A non-conductive material, milling technology, applied in the field of mechanical processing, can solve problems such as low processing efficiency, and achieve the effects of high processing efficiency, simple structure, and small macroscopic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

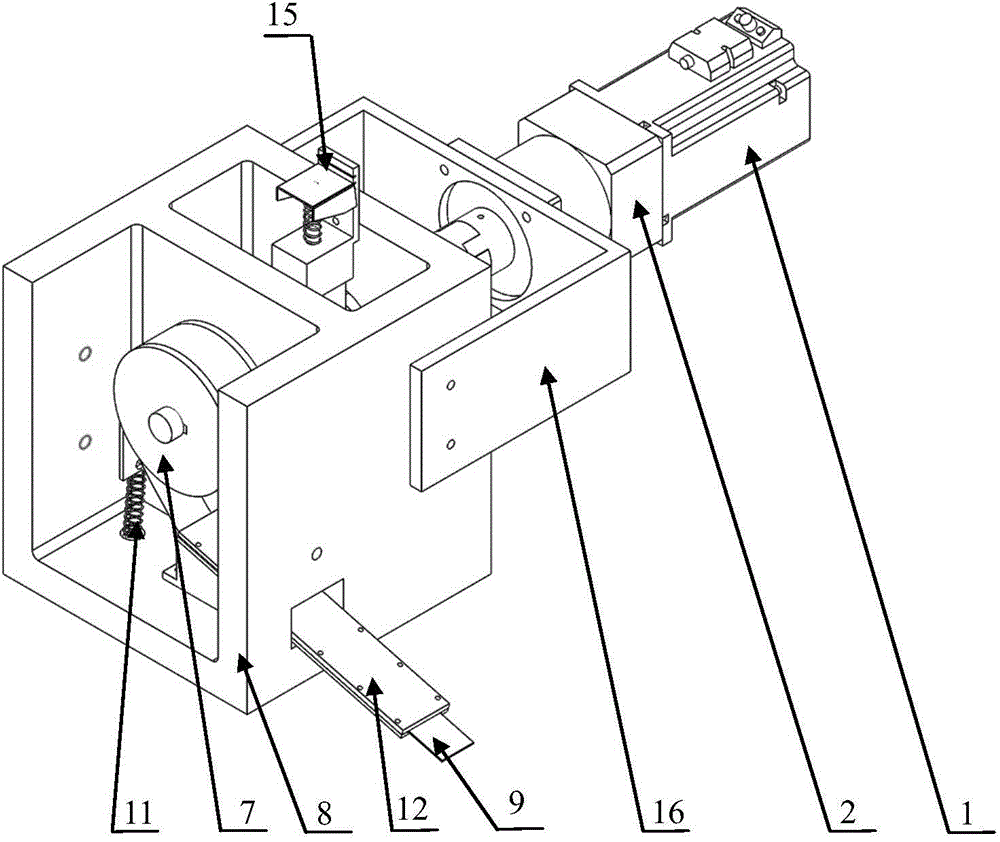

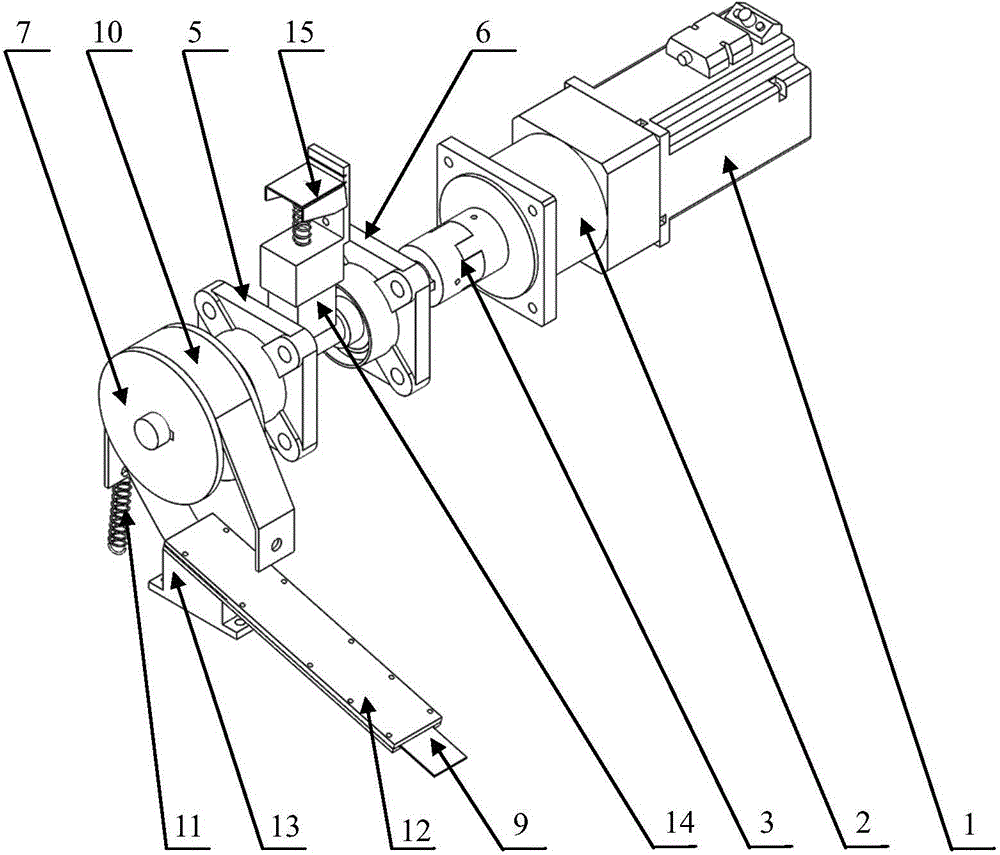

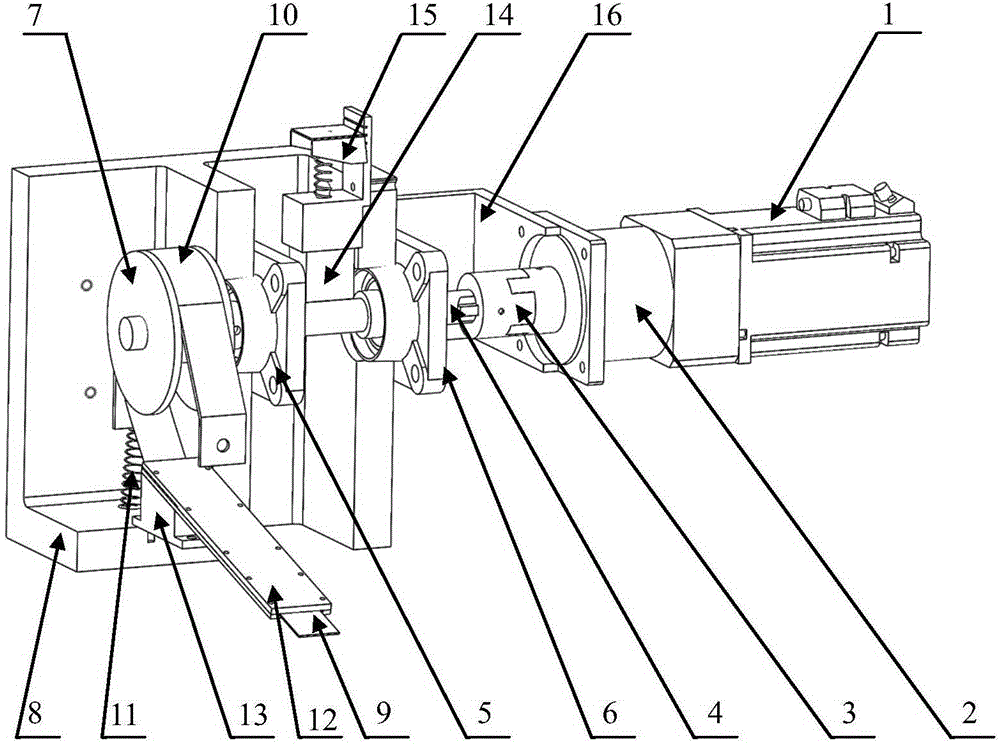

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the servo device for electric discharge milling of non-conductive materials mainly includes: servo motor 1, reducer 2, shaft 4, storage wheel 7, box body 8, and support frame 16; among them:

[0023] Casing 8 is casting, comprises base plate, three side plates that link to each other with base plate and the rib plate that is perpendicular to base plate, two parallel side plates, is provided with coaxial hole on rib plate and the side plate parallel with rib plate, so that To install the left bearing 5 and the right bearing 6 respectively, the box body 8 and the machine tool are connected and fixed by bolts.

[0024] The servo motor 1 is an AC servo motor, the servo motor 1 is connected to the speed reducer 2 by bolts, the speed reducer 2 is connected to the support frame 16 by bolts, and the support frame 16 is connected to the box body 8 by bolts.

[0025] The output shaft of the servo motor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com