Non-conducting material spark milling electrode tip

A non-conductive material and electric spark technology, applied in the field of mechanical processing, can solve problems such as poor processing environment, low processing accuracy, and poor surface quality, and achieve the effects of avoiding poor processing environment, reliable work, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

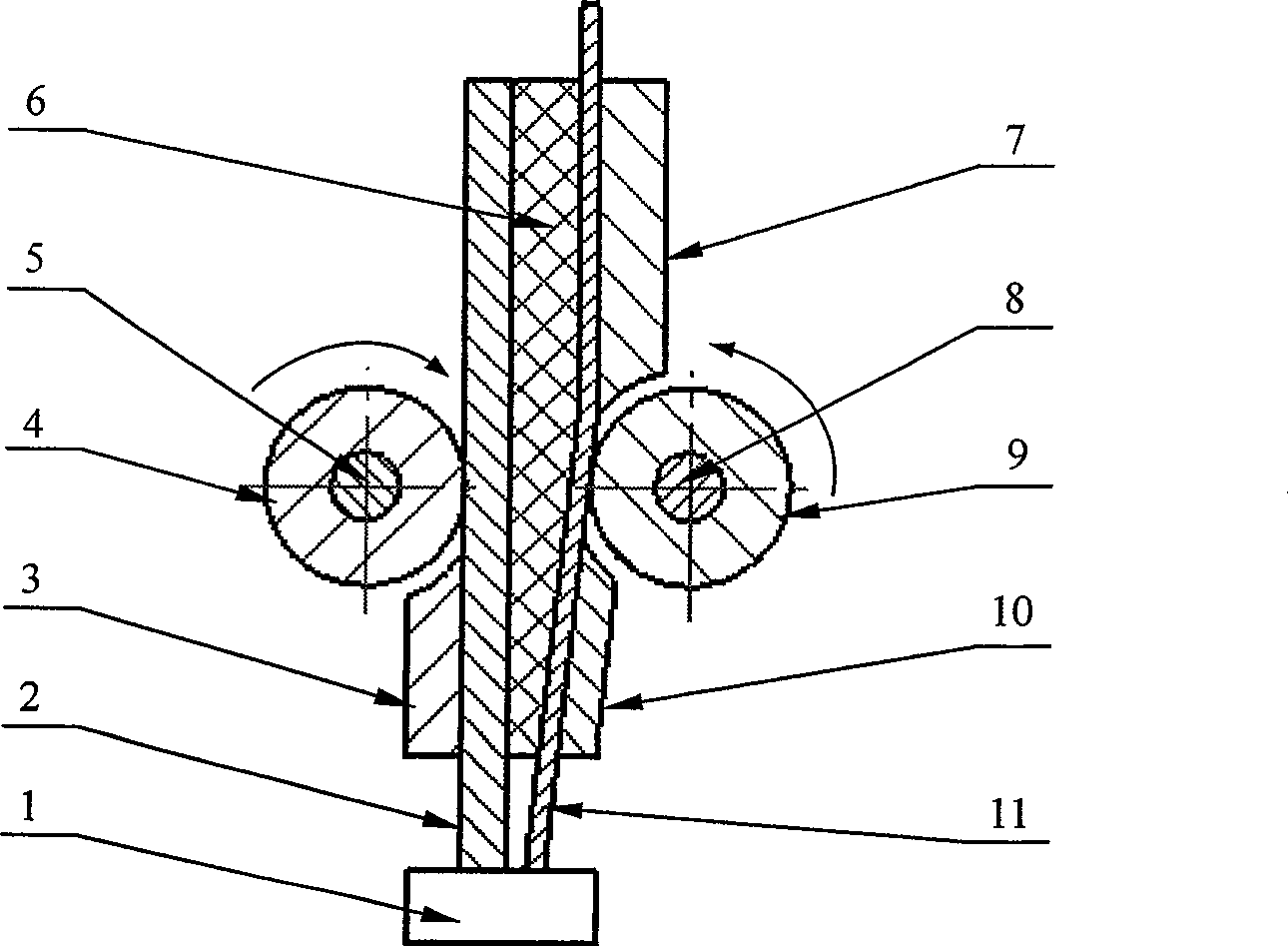

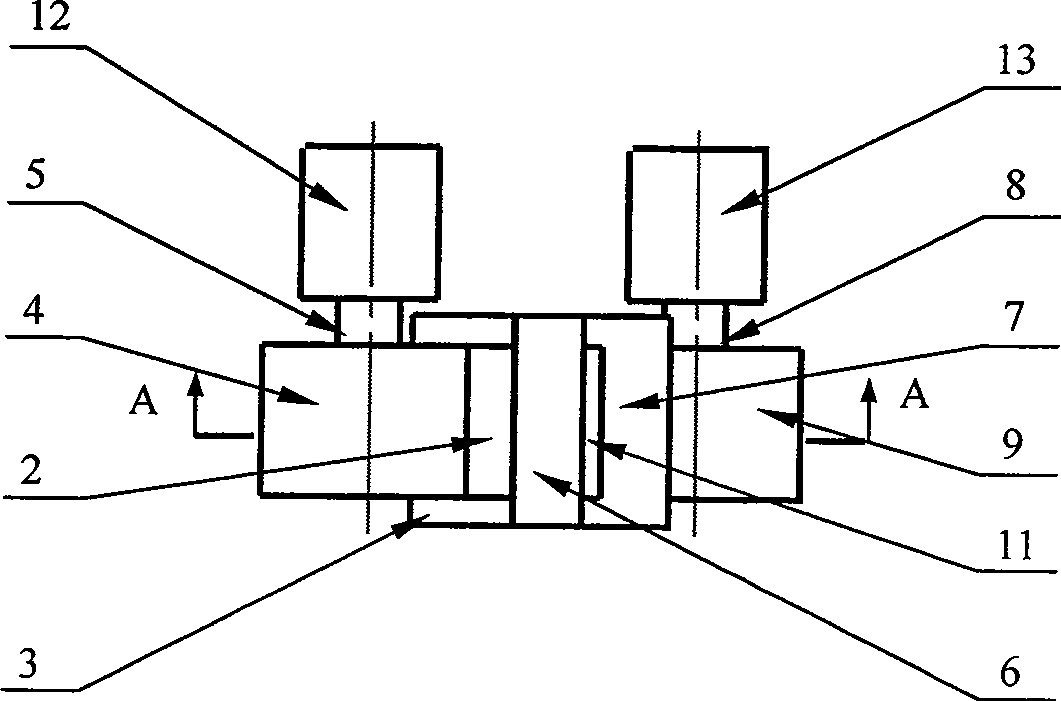

[0014] see figure 1 . The electrode head for electric spark planing of non-conductive material of the present invention comprises negative tool electrode 2, negative tool electrode guide plate 3, negative tool electrode driving wheel 4, negative tool electrode DC servo motor shaft 5, insulating partition 6, positive tool electrode Guide plate 7, positive tool electrode DC servo motor shaft 8, positive tool electrode drive wheel 9, positive tool electrode lower guide plate 10, positive tool electrode 11. The negative tool electrode 2 is connected to the negative pole of the electric spark pulse, and it is inserted into the guide groove formed by the negative tool electrode guide plate 3 and the insulating partition 6, and its lower end and the lower end of the positive tool electrode 11 are on the surface of the non-conductive material workpiece 1 Spark discharge is generated on the surface to form a spark discharge channel. The high temperature and high pressure generated whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com