A horizontal straight-through tube double-cavity wave power generation device

A power generation device and a straight-through pipe technology, which is applied in the direction of ocean energy power generation, engine components, machines/engines, etc., can solve the problems of low energy conversion efficiency, high cost of ocean engineering, high construction cost, etc., and achieve improved capture width ratio and safety High reliability, low cost of production and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

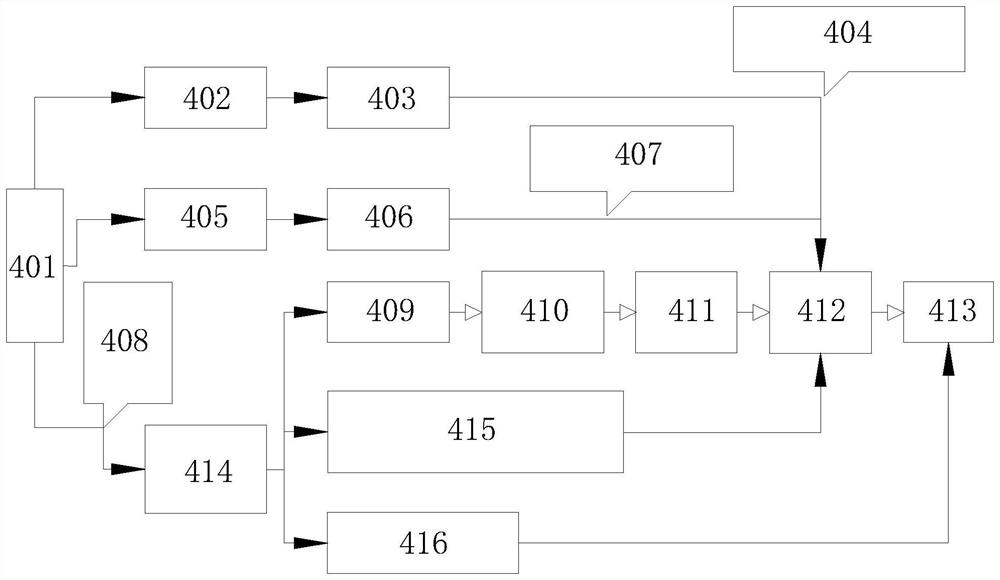

[0020] refer to figure 1 , the figure shows three prior art floating wave energy utilization technology classification diagrams; the reference signs in the figure represent respectively: 401, wave energy; 402, air kinetic energy; 403, air turbine; 404, oscillating water column technology ;405, seawater potential energy; 406, water turbine; 407, wave-surpassing technology; 408, oscillating float technology; 409, hydraulic cylinder; 410, high-voltage current regulator; 411, hydraulic motor; Structure mechanical energy; 415, mechanical structure (belt, gear transmission, etc.); 416, linear generator.

[0021] Floating motion oscillating water column technology mainly converts wave energy into the reciprocating motion of air chamber gas in the cavity of the floating body by the movement of the floating body, and then converts the aerodynamic energy into electrical energy through the air turbine and generator. This type of technology includes central tube technology and back bendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com