Piezoelectric-driven micro-motor device based on cantilever beam vibration and working method thereof

A piezoelectric drive, micro-motor technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problems of high processing precision and complex structure, etc. It can achieve the effect of simple installation, high movement precision, and control of movement direction and angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] The present invention will be further described in detail below in conjunction with specific embodiments, which are to explain rather than limit the present invention.

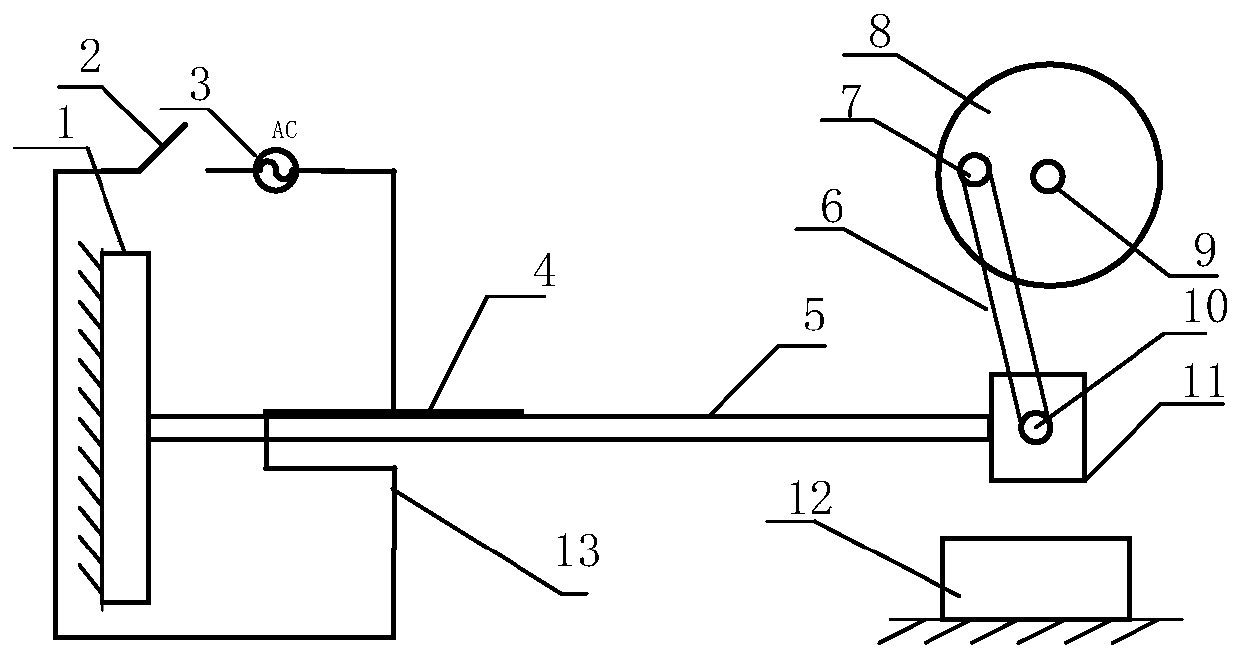

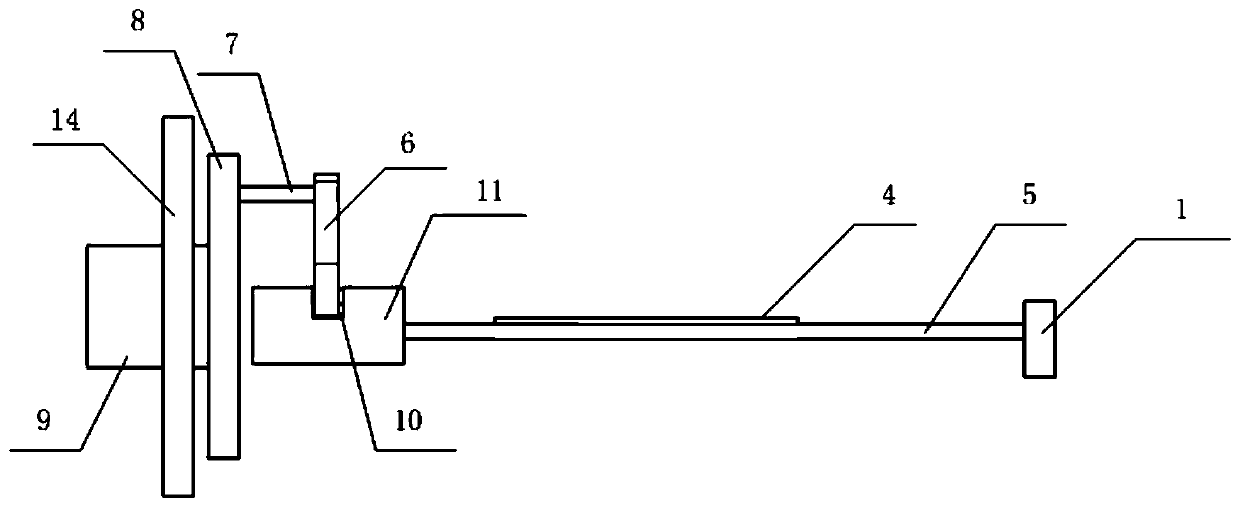

[0032] like Figures 1 to 2 As shown, the piezoelectric drive micromotor device based on cantilever beam vibration of the present invention includes three parts: a microcantilever beam piezoelectric drive system, a power output system and a motor start-stop system. The micro-cantilever piezoelectric drive system includes a first fixed end 1, a piezoelectric sheet 4 and a micro-cantilever beam 5; the power output system includes a mass 11, a hinge 10, an inertia wheel shaft 9, a connecting rod 6 and an inertia wheel 8; the motor starts and stops The system includes a circuit, and the circuit includes a power switch 2 and an AC power source 3 .

[0033] The left end of the micro-cantilever beam 5 is fixedly connected to the first fixed end 1, and the right end is fixedly connected to the mass block 11. T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap