Centrifuge and swing-out rotor

A centrifuge and rotor technology, applied in centrifuges and other directions, can solve problems such as large space and large centrifuge size, and achieve the effect of reducing energy demand, ensuring stability, and reducing inertial mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

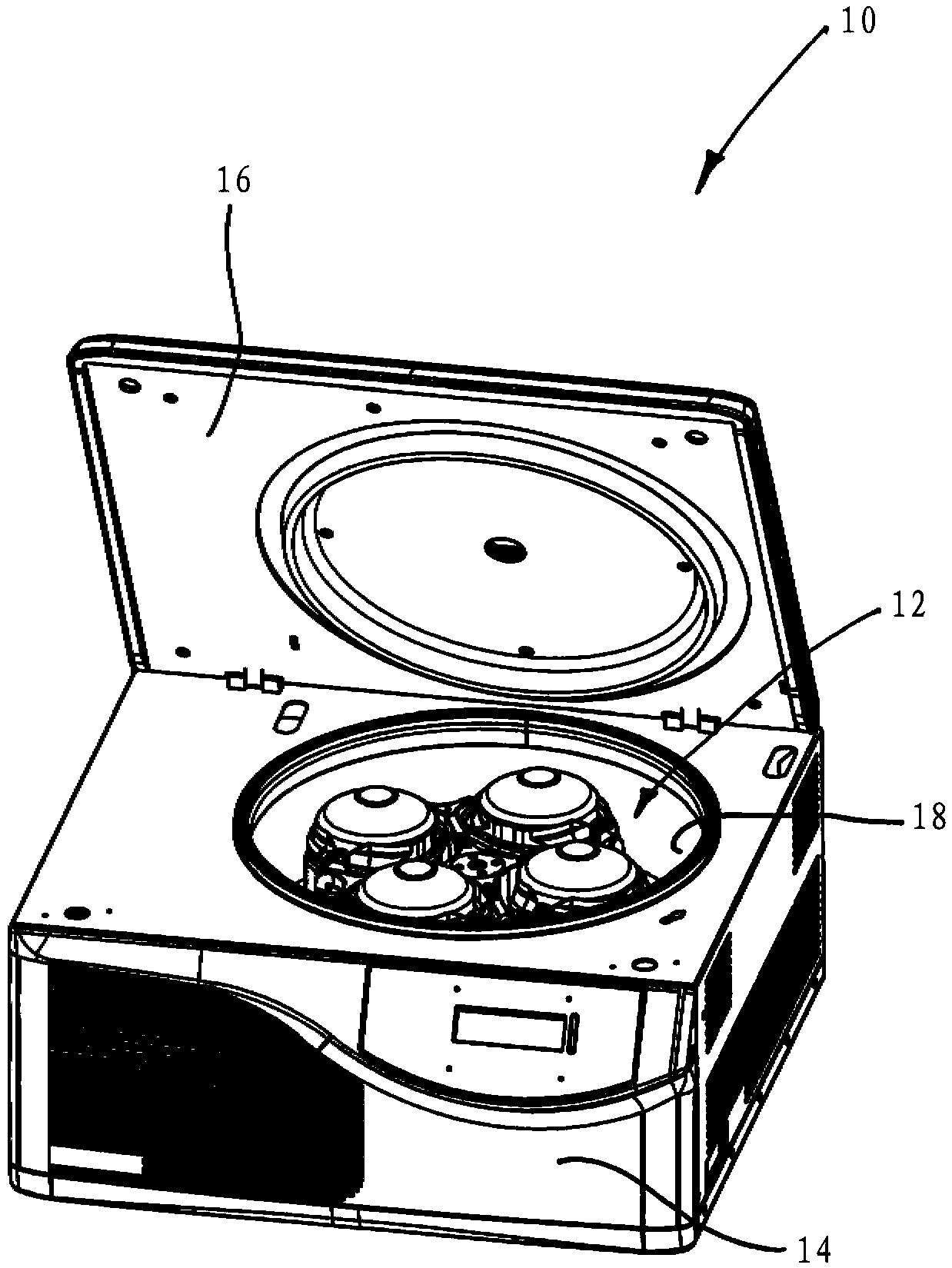

[0036] Figure 1 to Figure 5 A first example of a centrifuge 10 is shown with an oscillating rotor 12 inserted therein.

[0037] The centrifuge 10 is configured as a laboratory centrifuge having a housing 14 with a cover 16 . In the centrifuge container 18 of the centrifuge 10 , the oscillating rotor 12 is arranged on a drive shaft (not shown) of a centrifuge motor (not shown).

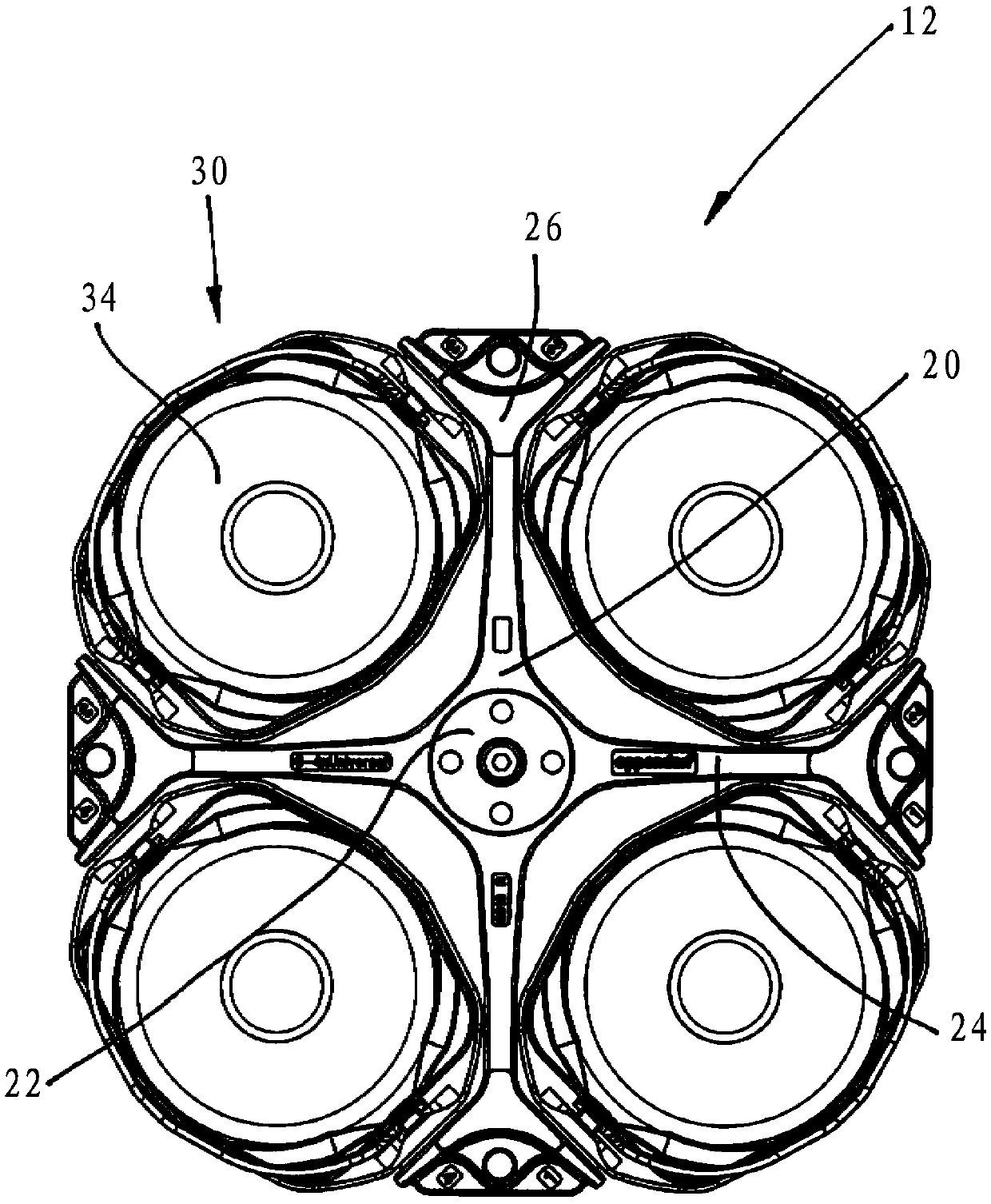

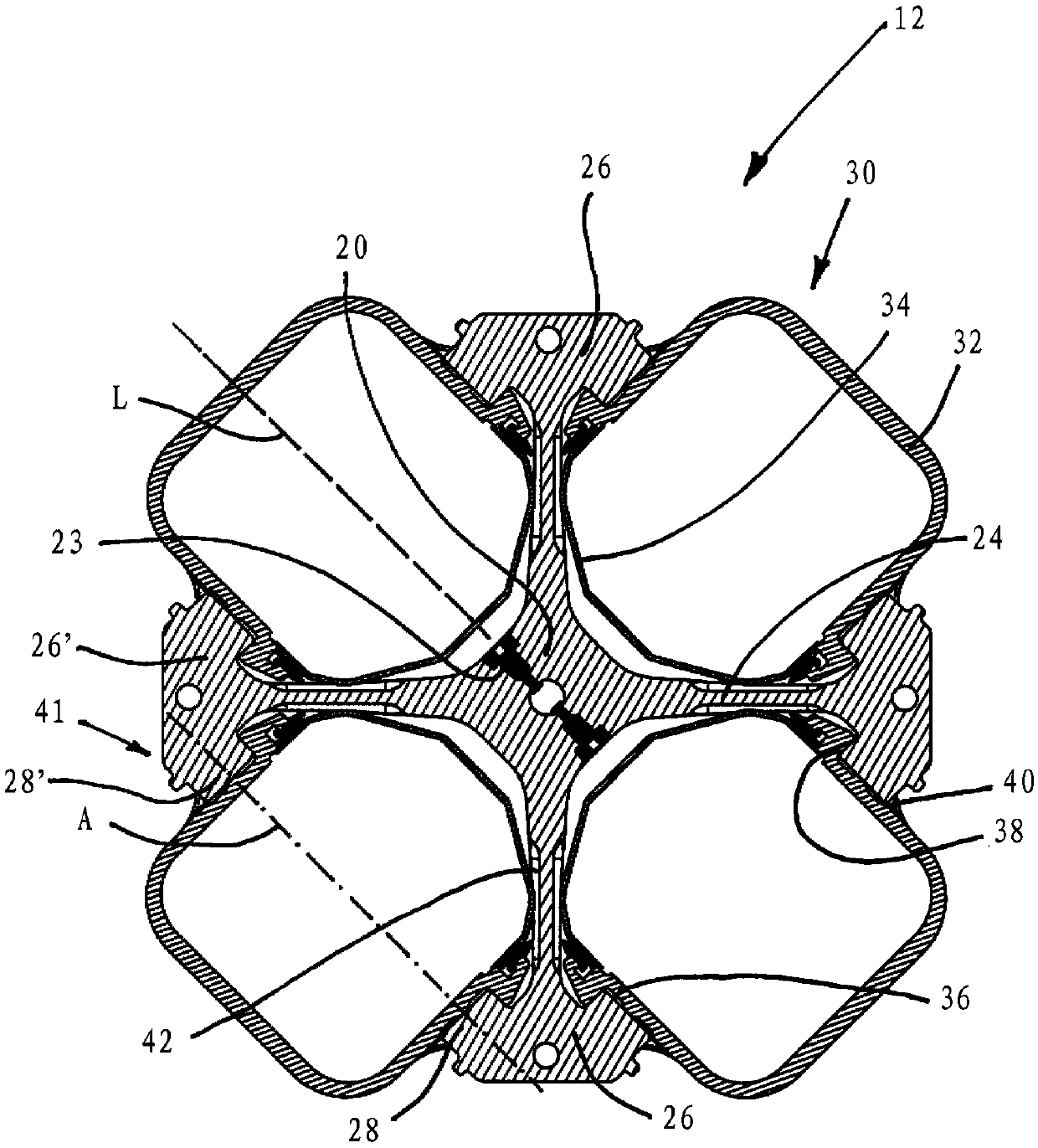

[0038] The oscillating rotor 12 has a rotor base body 20 with a hub 22 which is coupled to the drive shaft via screws 23 . The rotor base body 20 has four rotor arms 24 which are each arranged on a hub 22 which are offset from each other by 90° in the circumferential direction. The rotor arms 24 open out into arm branches 26 in which two retaining pins 28 are arranged. The oppositely arranged retaining pins 28 , 28 ′ of the two oppositely arranged arm branches 26 , 26 ′ are aligned such that they are aligned and thus form the swing-out axis A .

[0039]The suspension 30 is configured as a tub 32 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com