Turnover box based on corner lock fastening

A turnover box and corner lock technology, which is applied in the direction of locking equipment, rigid containers, containers, etc., can solve the problems of pollution, turnover box fasteners scratching each other, loss of transported goods in the box, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

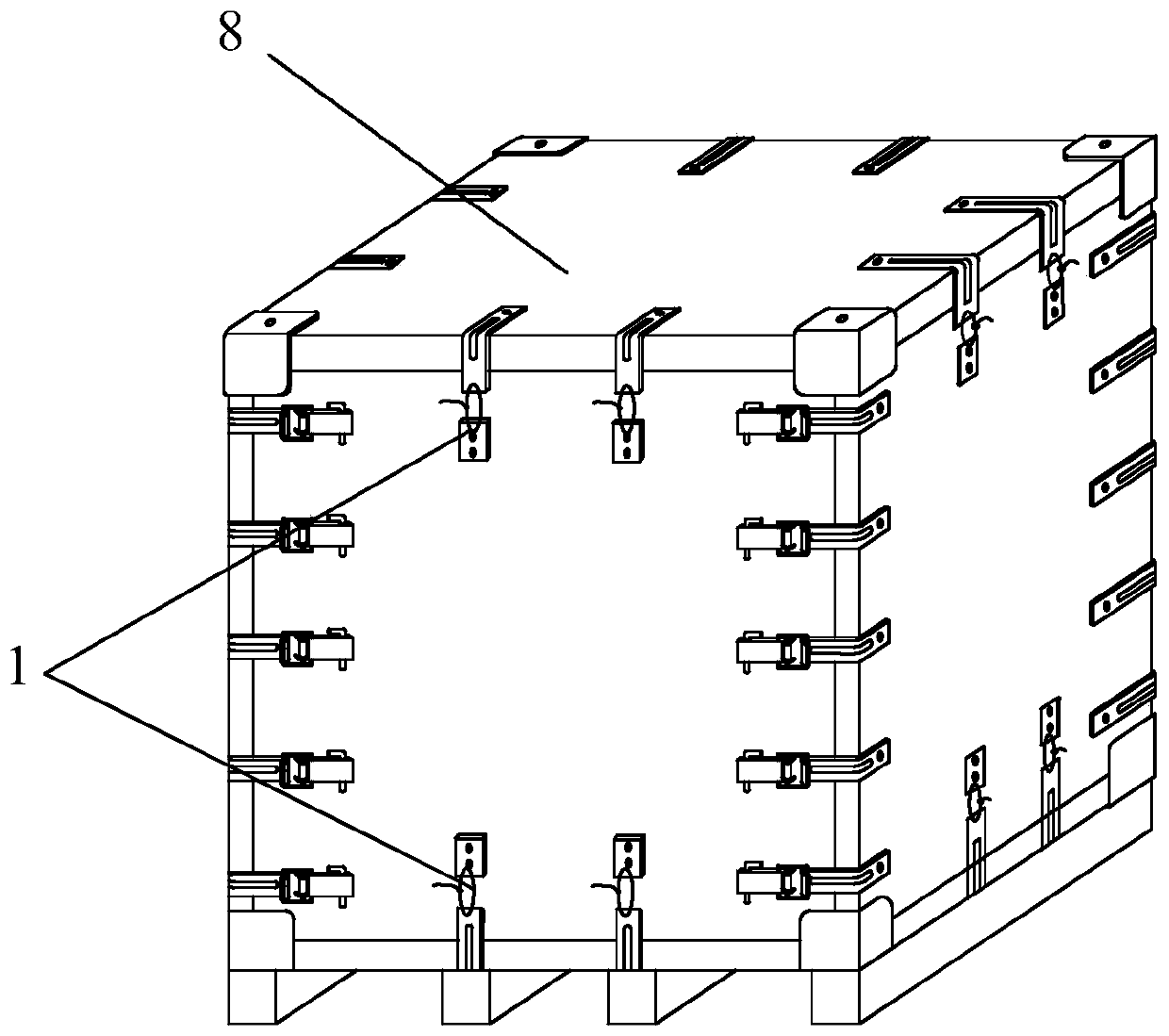

[0023] Such as figure 1 As shown, a turnover box (for transporting liquid) based on corner lock fastening includes a hollow box body 8 composed of six box panels, and the box cover of the hollow box body 8 and the adjacent side panels pass through The corner lock 1 is fastened and connected; the side box panels can be connected by a lock, or can be connected by the corner lock 1 (choose according to the demand). The top corner of the hollow box 8 is provided with an anti-collision corner .

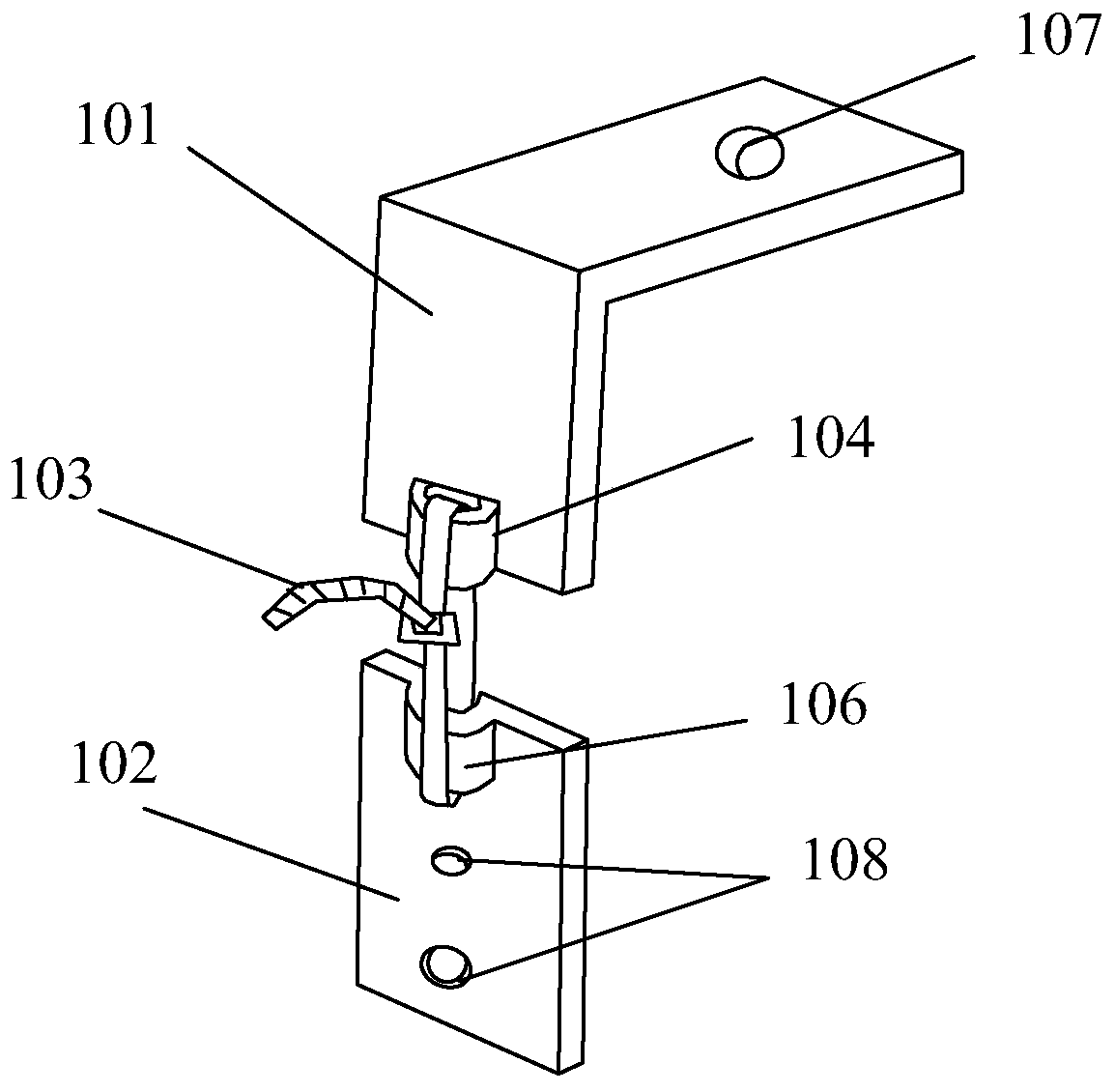

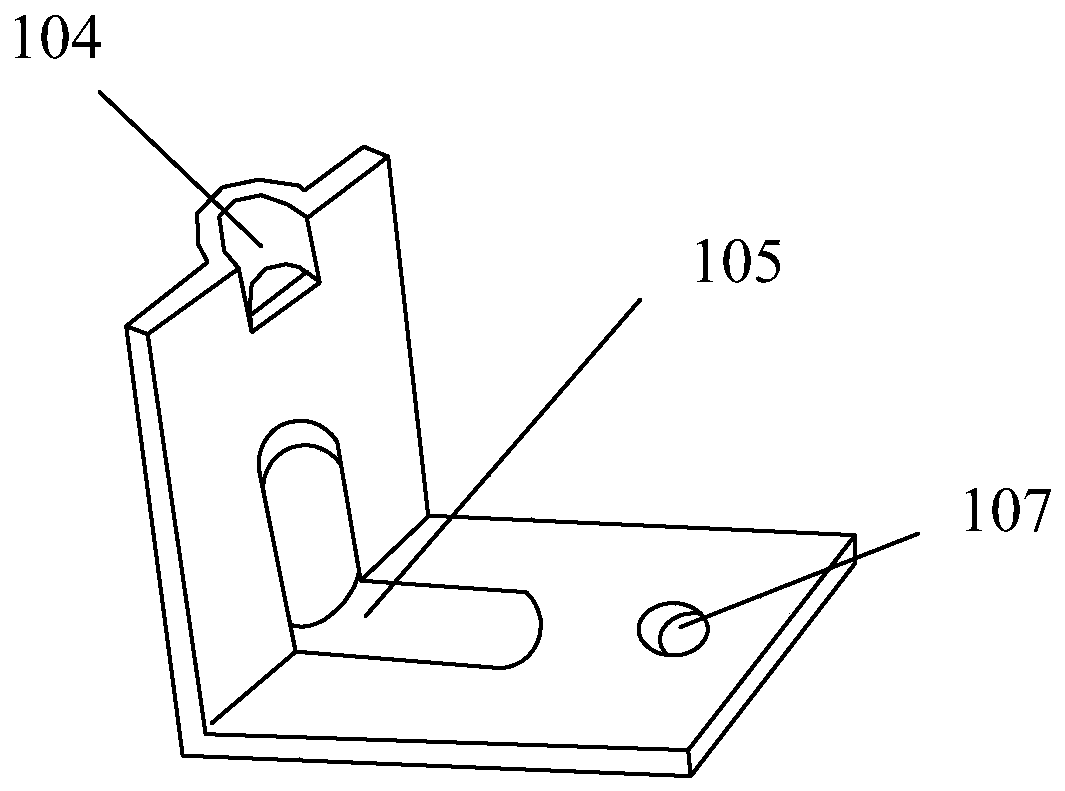

[0024] The corner lock 1 includes an elongated L-shaped locking piece 101 arranged at the corner of the hollow box 8, a straight locking piece 102 on the box plate adjacent to the corner where the L-shaped locking piece 101 is located, And the locking bar 103 connecting the L-shaped locking piece 101 and the straight locking piece 102 . The locking bar 103 is locked by a one-time tensioning locking bar to prevent losses caused by misoperation or illegal operation during transportation. ...

Embodiment 2

[0026] Embodiment 2: as figure 1 As shown, a turnover box (for transporting solids) based on corner lock fastening includes a hollow box body 8 composed of six box panels, and the adjacent box panels of the hollow box body 8 pass through corner locks 1 Tight connection; the side box panels can be connected by locks, or can be connected by the corner lock 1 (selected according to requirements), and the top corner of the hollow box body 8 is provided with an anti-collision fixed angle.

[0027] Such as image 3 As shown, the corner lock 1 includes an L-shaped locking piece 101 arranged at the corner of the hollow box 8, a straight locking piece 102 on the box plate adjacent to the corner where the L-shaped locking piece 101 is located, And the locking bar 103 connecting the L-shaped locking piece 101 and the straight locking piece 102 . The locking bar 103 is locked by a one-time tensioning locking bar to prevent losses caused by misoperation or illegal operation during transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com