Industrial preparation method of 2,6-di-o-methyl-β-cyclodextrin and its inspection method

A technology of cyclodextrin and dimethylformamide, applied in 2 fields, can solve problems such as few indicators for controlling product quality, and achieve the effects of good prevention of pertussis in children, significant social benefits, and strict performance testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

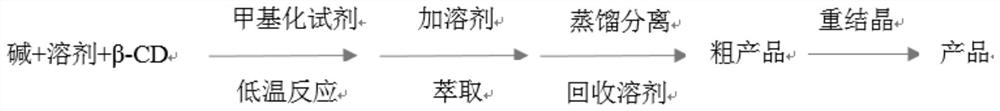

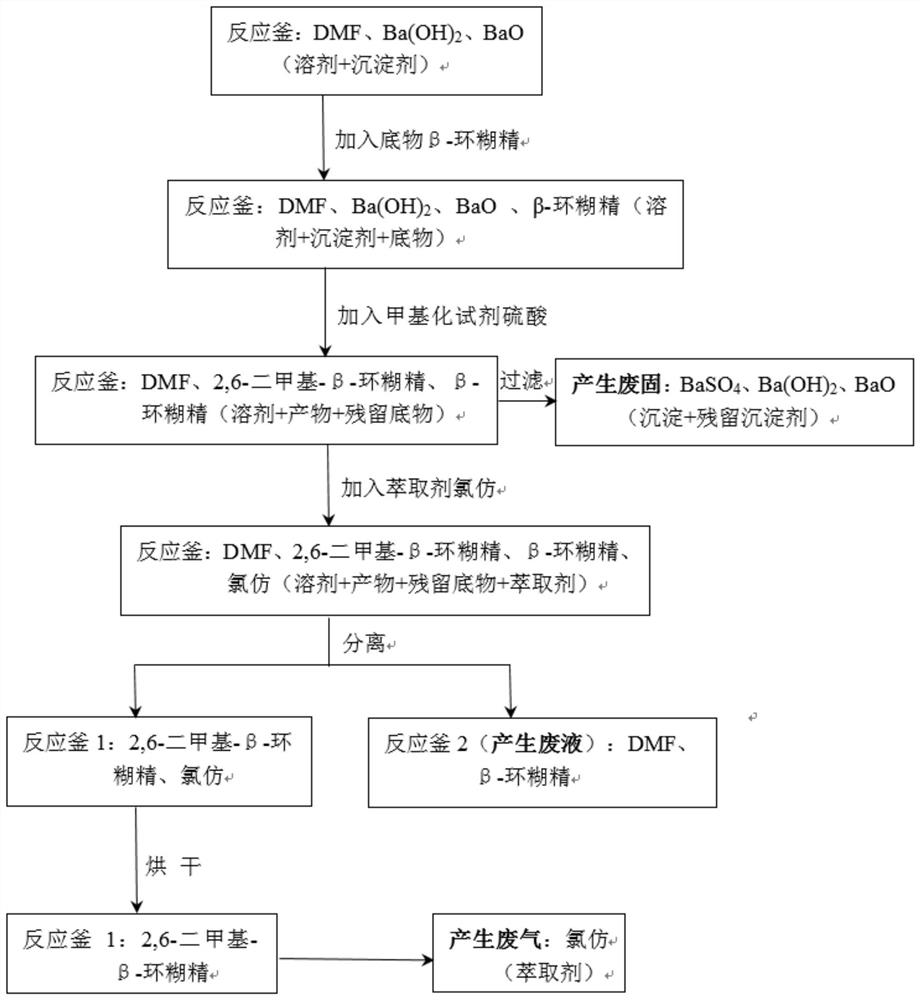

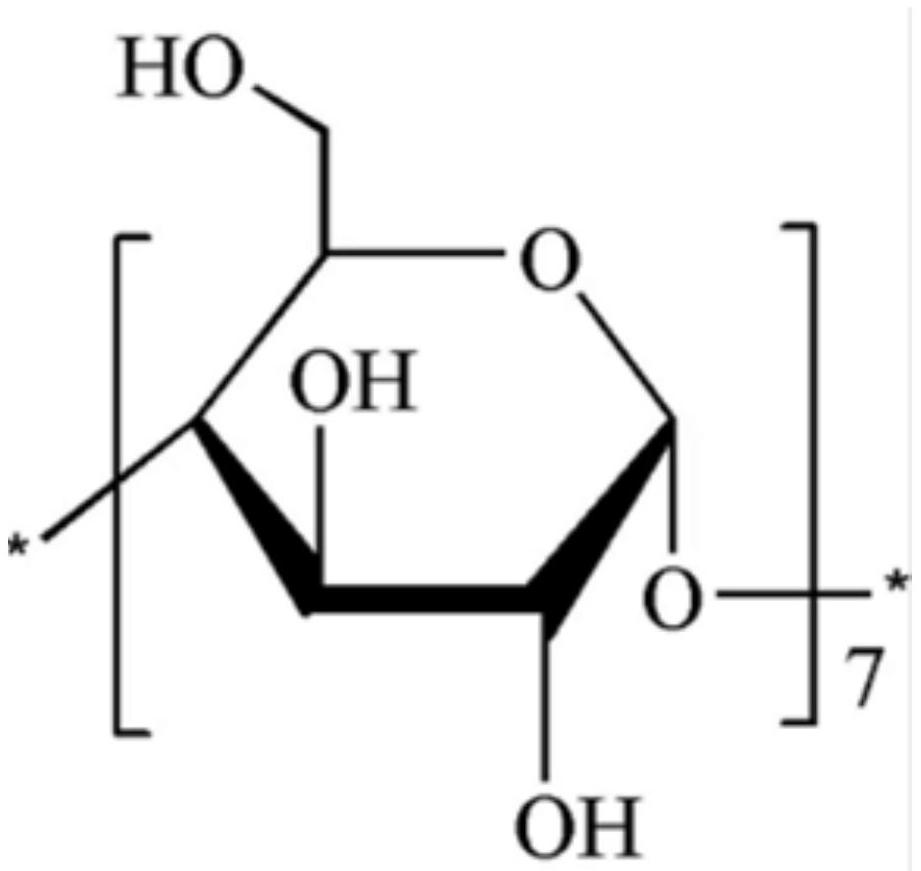

[0031] The present invention provides a kind of 2,6-di-O-methyl-beta-cyclodextrin industrial mass preparation method, such as figure 1 and figure 2 shown, including the following steps:

[0032] S1: Dry the β-cyclodextrin before feeding, the temperature is controlled at 90°C-130°C, the drying time is 2-15 hours, and the water loss rate is 3%-20%.

[0033] S2: Add anhydrous barium oxide, barium hydroxide, and N,N-dimethylformamide in turn to reaction kettle 1, stir well, cool down to +10°C to -10°C and keep; anhydrous barium oxide, barium hydroxide , The mass ratio of N,N-dimethylformamide to β-cyclodextrin is 30:50:(40~70):(10~35), and β-cyclodextrin is added in 1~5 times , with an interval of 5 to 30 minutes between two adjacent times, and continue to stir for 0.5 to 3 hours after adding all of them; then add methyl sulfate dropwise, the mass ratio of methyl sulfate to β-cyclodextrin is 24: (10 to 25), methyl sulfate The ester is divided into 1 to 5 parts on average, each...

Embodiment 1

[0075] This embodiment provides an industrial mass production method of 2,6-di-O-methyl-β-cyclodextrin, comprising the following steps:

[0076] S1: Dry the β-cyclodextrin before feeding, the temperature is controlled at 130°C, the drying time is 2 hours, and the water loss rate is 20%.

[0077] S2: Add anhydrous barium oxide, barium hydroxide, N,N-dimethylformamide in sequence to reaction kettle 1, stir well, cool down to 10°C and keep; anhydrous barium oxide, barium hydroxide, N,N- The mass ratio of dimethylformamide to β-cyclodextrin is 30:50:40:35, and β-cyclodextrin is added in 5 times, with an interval of 5 minutes between two adjacent times, and stirring is continued for 3 hours after all additions are completed; Then add methyl sulfate dropwise, the mass ratio of methyl sulfate to β-cyclodextrin is 24:10, methyl sulfate is divided into 5 parts on average, each part is added dropwise for 1.5 hours, and stirred for 60 minutes; after all the drops are completed, continue ...

Embodiment 2

[0084] This embodiment provides an industrial mass production method of 2,6-di-O-methyl-β-cyclodextrin, comprising the following steps:

[0085] S1: Dry the β-cyclodextrin before feeding, the temperature is controlled at 90°C, the drying time is 15 hours, and the water loss rate is 3%.

[0086] S2: Add anhydrous barium oxide, barium hydroxide, and N,N-dimethylformamide in turn to reaction kettle 1, stir well, cool down to -10°C and keep; anhydrous barium oxide, barium hydroxide, N,N - The mass ratio of dimethylformamide to β-cyclodextrin is 30:50:70:10, and β-cyclodextrin is added in 2 times, with an interval of 30 minutes between two adjacent times. After all additions, continue stirring for 0.5 h; then add methyl sulfate dropwise, the mass ratio of methyl sulfate to β-cyclodextrin is 24:25, methyl sulfate is divided into 2 parts on average, each part is added dropwise in 4 hours, and stirred for 15 minutes; after all the drops are completed The stirring reaction was continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com