Ammonia injection optimization adjustment device and method based on inlet flow field distribution of denitration device

A technology for adjusting devices and inlet flow, which is applied in the field of flue gas denitrification, can solve the problems of excessive ammonia injection and uneven distribution of flue gas flow, and achieve the solution of excessive and insufficient ammonia injection, uneven distribution of inlet flow field, and data processing process. concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

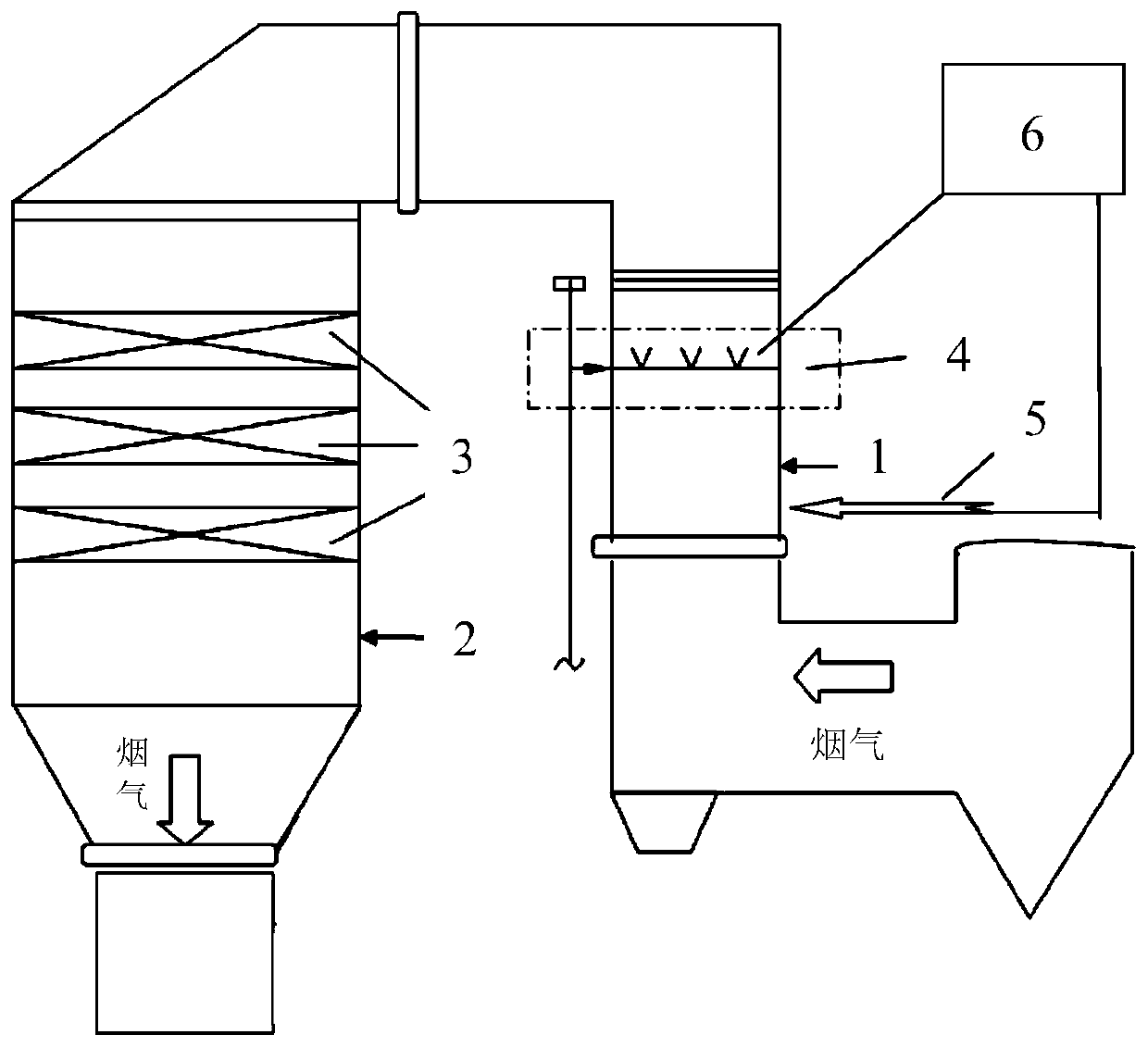

[0069] This embodiment provides an ammonia injection optimization adjustment device based on the distribution of the inlet flow field of the denitrification device (SCR denitrification device, including the catalyst module 3 and the ammonia injection grid 4), wherein the structural diagram of the device is as follows figure 1 shown, from figure 1 As can be seen from the figure, it includes several speed measuring tubes 5 and control units 6;

[0070] Wherein, the velocity measuring tube is a velocity measuring tube for measuring the dynamic pressure of the flue gas at the injection point on the ammonia injection plane in the flue at the inlet 1 of the denitrification device;

[0071] Each injection point is also provided with a corresponding ammonia injection regulating valve;

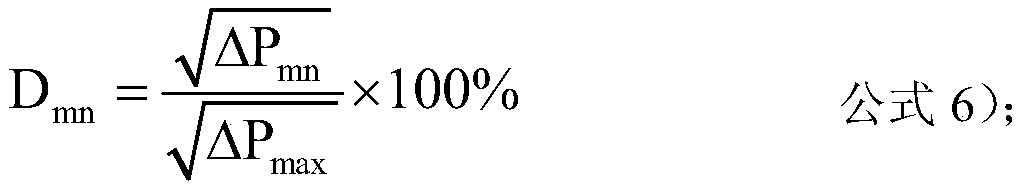

[0072] The control unit is electrically connected to several velocity measuring tubes respectively, and it includes a first computing unit and a second computing unit; the first computing unit is used...

Embodiment 2

[0076] This embodiment provides a method for optimizing the adjustment of ammonia injection based on the distribution of the inlet flow field of the denitrification device (SCR denitrification device), wherein the method is to use the optimal adjustment of ammonia injection based on the distribution of the inlet flow field of the denitrification device provided in Example 1 device, which includes the following steps:

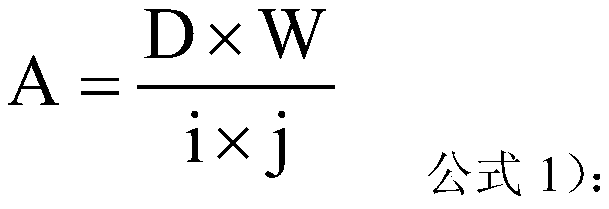

[0077] (1) Determine the number of test injection points (ammonia injection points) on the ammonia injection plane in the flue at the entrance of the SCR denitrification device, which specifically includes:

[0078] The depth D of the ammonia injection plane at the inlet of the SCR denitration device in a coal-fired power plant is 3m, and the width W is 5m. Query the engineering design drawings of the denitrification device of the power plant, and determine the layout of the ammonia injection points on the ammonia injection plane as (3×5). Arrange (3×5) measuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com