MEMS micro-heater with an integrated temperature sensor

A temperature sensor and micro-heater technology, applied in the sensor application field, can solve the problems that the chip cannot be completely packaged, the temperature measurement of the micro-heater is difficult, and the temperature state of the micro-heater cannot be accurately measured. The effect of low power consumption and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

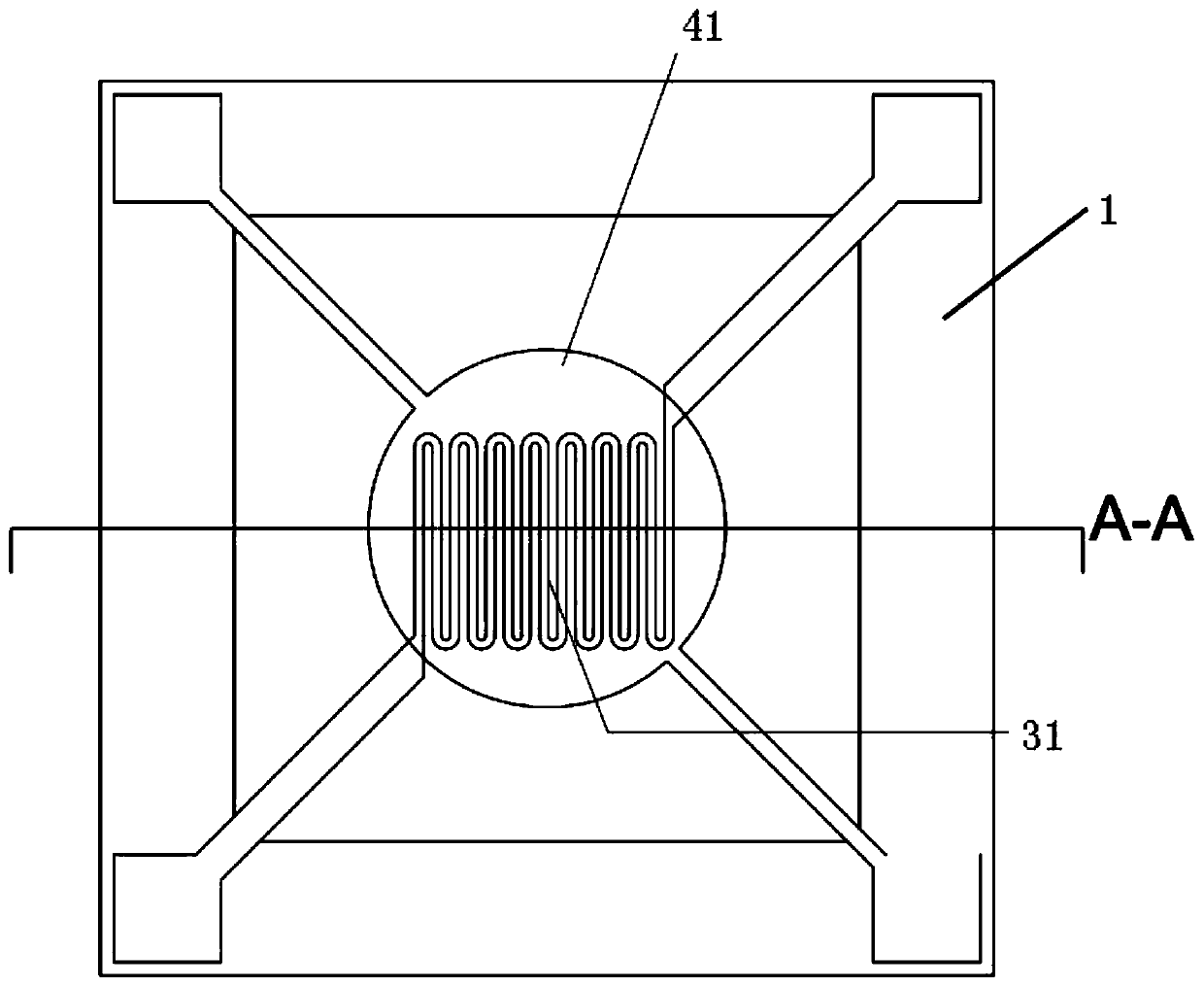

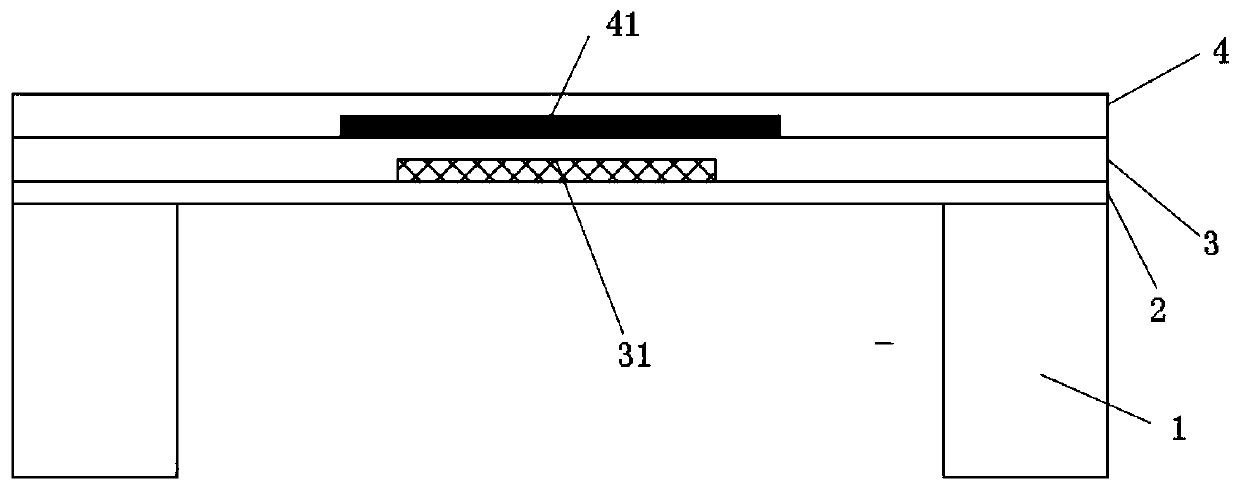

[0021] see Figure 1 to Figure 2 , the present embodiment shows a MEMS micro heater with an integrated temperature sensor, including a silicon substrate 1, which is sequentially arranged on the silicon substrate 1 to carry out a variety of MEMS processing processes to obtain an insulating and heat-insulating layer 2, an insulating layer B3, an insulating layer A4;

[0022] The insulating layer A4 is provided with a heating layer accommodation groove corresponding to the end plane of the insulating layer B3, and the insulating layer B3 is provided with a temperature sensor accommodation groove on the end plane facing away from the insulating layer A4, and the heating layer accommodation groove and the temperature sensor accommodation groove are respectively provided with a heating layer 31 and the temperature sensor 41; the insulating layer A3 and the heating layer 31 form a heating structure, and the temperature sensor 4 and the insulating layer B41 form a temperature detectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com