A Method for Measuring Wall Shear Stress

A measurement method and technology of shear stress, which are applied in measurement devices, measurement of fluid pressure, and hydrodynamic tests, etc., can solve the problems of inability to measure the near-wall area at the same time, limited application range, and difficulty in obtaining dynamic information of wall shear stress, etc. Suppresses the formation of flow structures with large shear stress, promotes the formation of flow structures with small shear stress, and is beneficial to drag reduction and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

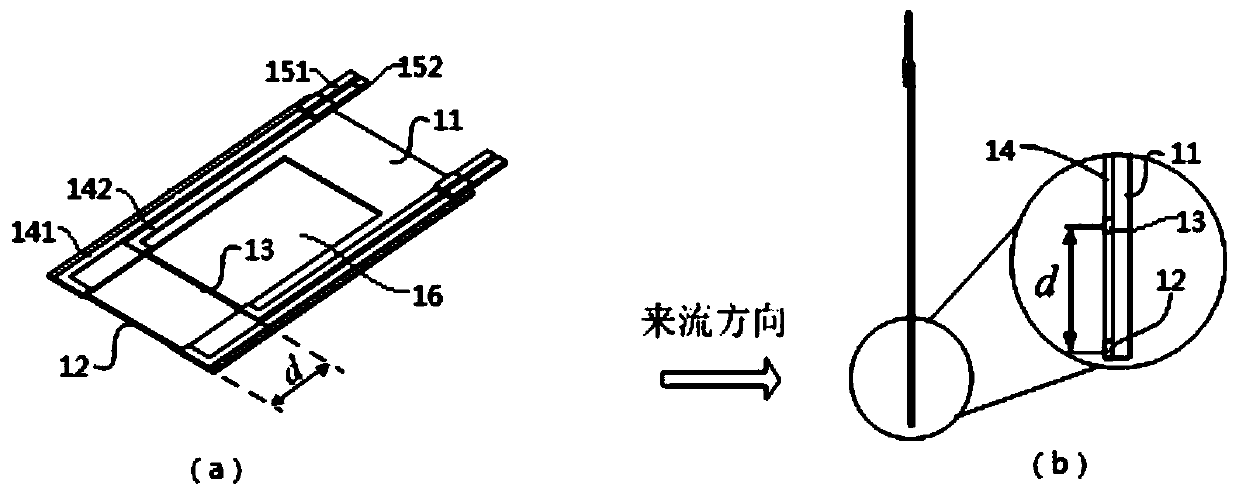

[0057] The parallel array hot wire probe of the present embodiment, such as image 3 As shown, it includes an insulating base 11, a first thermosensitive element 12 and a second thermosensitive element 13, wherein the insulating base 11 is in a substantially concave shape, and one end is the end near the wall (such as image 3 The left end shown in (a)) is provided with ventilation groove 16, and the first thermosensitive element 12 and the second thermosensitive element 13 are collinearly arranged at intervals, and the distance is d, and the first thermosensitive element 12 and the second thermosensitive element Both ends of 13 are fixed on the insulating base 11 and both straddle the ventilation groove 16; the first thermosensitive element 12 and the second thermosensitive element 13 are all platinum wires, thermocouples or other thermistors, which are not specifically limited The two ends of the first thermal element 12 are respectively connected with the first copper-clad ...

Embodiment 2

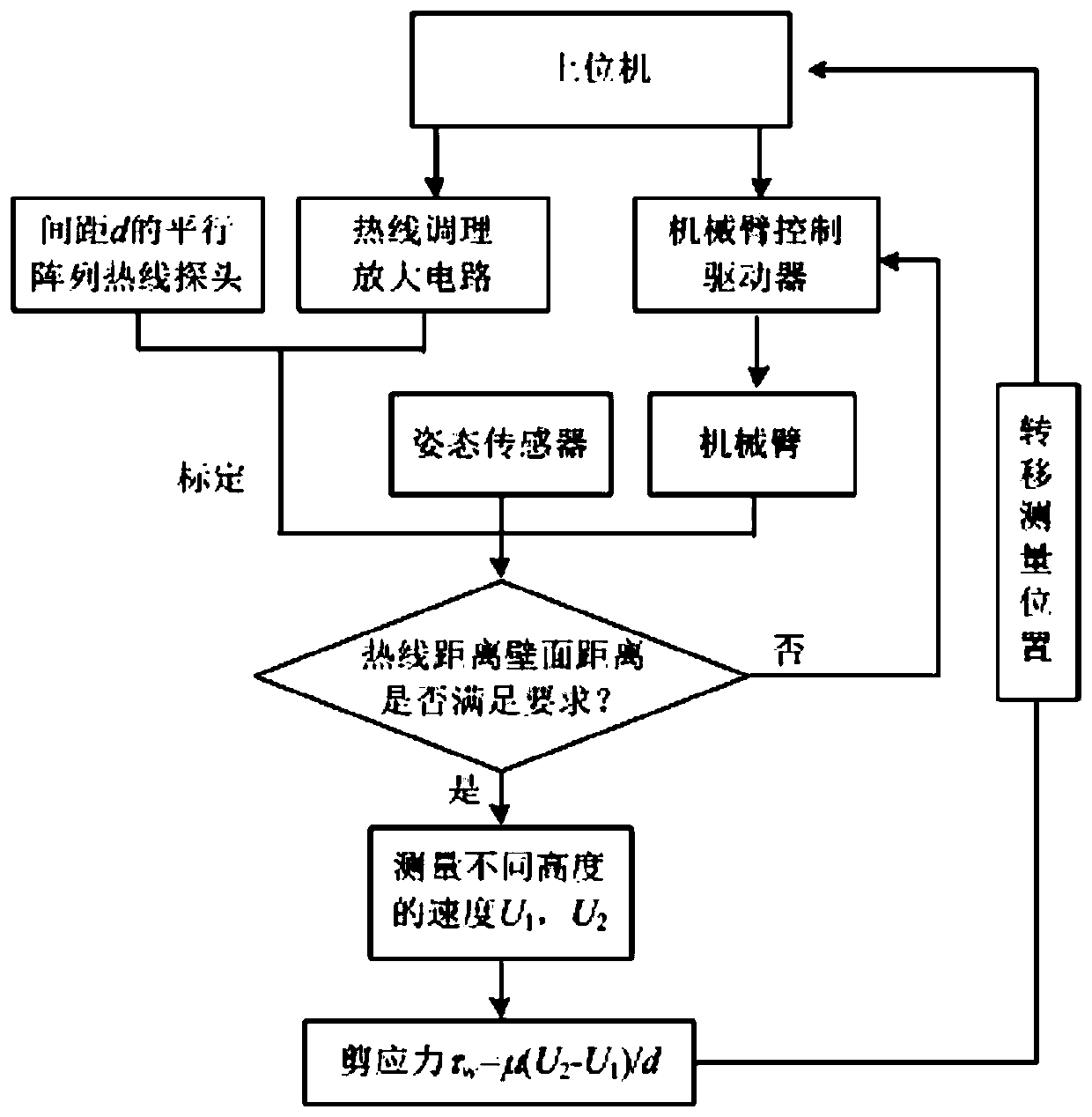

[0060] The wall shear stress measuring method of the present embodiment, such as Figure 1 to Figure 8 shown, including the following steps:

[0061] S1: Turn on the host computer 6, and set measurement tasks on the host computer 6;

[0062] The measuring task of upper computer 6 comprises position distribution and sampling frequency of points to be measured, and the sampling frequency of the hot-wire velocimeter of the present invention is up to 50KHz, and the higher the sampling frequency, the larger the data point value of collection; the sampling frequency can be selected according to demand, For example, a frequency of 1 KHz is adopted.

[0063] S2: Prepare the test piece, set the incoming flow velocity, and the direction of the incoming flow velocity is collinear with the plane where the wall surface of the test piece is located;

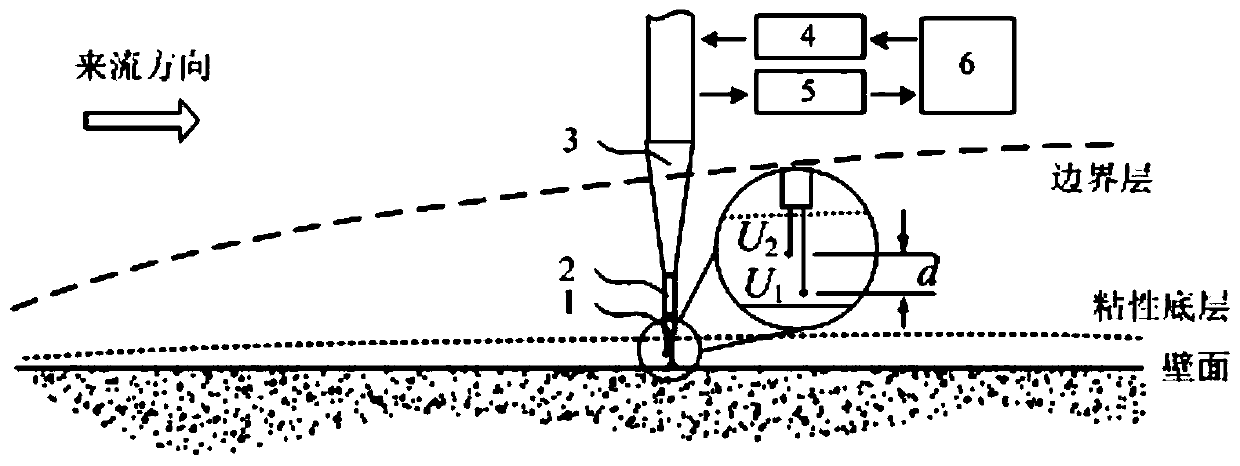

[0064] Such as figure 2 and image 3 As shown, the direction of the incoming flow is collinear with the plane where the wall surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com