Zeroing algorithm of pointer instrument

A pointer and instrument technology, applied in the field of automobile pointer instruments, can solve the problems of zeroing and stop zeroing command amplification, instrument pointer deviation from the zero position of the scale, affecting the use of pointer instruments, etc., so as to reduce the zeroing error and the zeroing speed. The effect of fast, increasing the range of rotation available

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

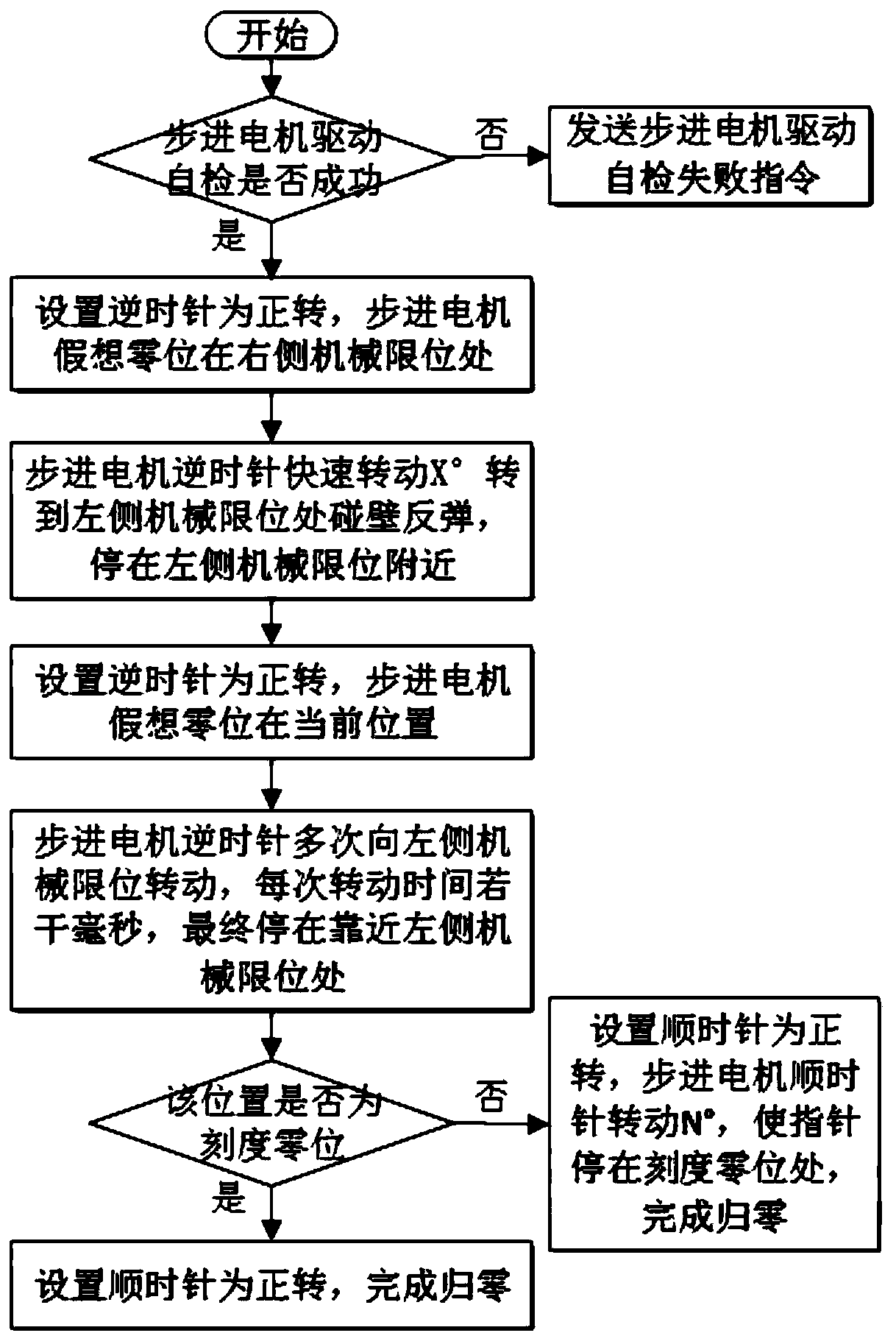

[0025] The zero return and stop zero return instructions will greatly amplify the error caused by the different initial positions, so the present invention no longer uses these two instructions, and uses a new zero return algorithm to complete the zero return. The zeroing algorithm is solidified in the DSP chip, and its main task is to make the pointer be at the same position as close to the mechanical limit of a certain stepping motor as possible before each work, and set this position or the position N° away from this position as the instrument The zero position of the scale, the zero position of the scale here can be 0 on the scale, or other scale numbers as required. Such as figure 1 As shown, the pointer is close to the mechanical limit on the left side of the stepper motor when the pointer is at the zero position of the scale as an example. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com