Automatic locking device for vertical shaft explosion-proof cover inverted ventilation

An automatic locking, explosion-proof cover technology, applied in mine/tunnel ventilation, non-mechanical transmission-operated locks, building locks, etc. and other problems to achieve the effect of preventing excessive sliding, reducing the incidence of accidents, and making the device simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

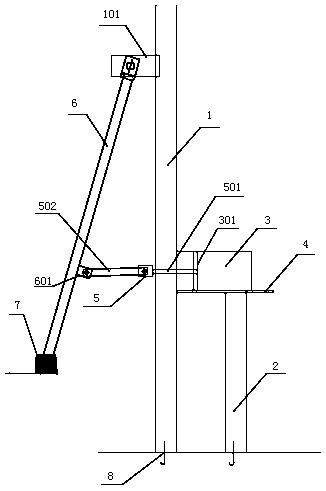

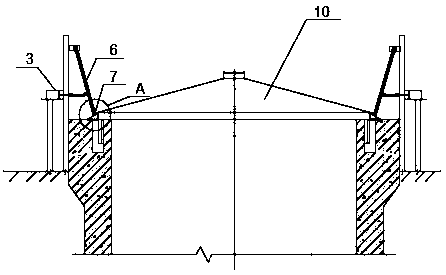

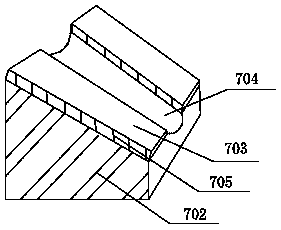

[0030] An automatic locking device for anti-wind of shaft explosion-proof cover, such as figure 2 As shown, the automatic locking device is arranged around the edge of the explosion-proof cover 10, and is characterized in that it includes at least three sets of locking mechanisms uniformly arranged on the edge of the explosion-proof cover 10, and each set of locking mechanisms includes a pressing block 701 and a pad 702. The locking assembly 7, wherein, the pad 702 is fixed on the edge of the explosion-proof cover 10 by bolts, and it has an upward slope 703, and there is a certain angle between the slope 703 and the horizontal plane, and the smaller the angle is , the greater the vertical pressure of the pressure block 701 on the cushion block 702, the explosion-proof cover 10 will be locked under the action of force, which can effectively prevent the explosion-proof cover 10 from being pushed open by the positive pressure air flow in the reverse wind and cause a short circuit...

Embodiment 2

[0034] This embodiment is an improvement on the basis of Embodiment 1, as figure 1 and 4 As shown, a circle of L-shaped clamping plate 9 is arranged around the edge of the explosion-proof cover 10, and the L-shaped clamping plate 9 has a vertical plate 901 close to the edge of the explosion-proof cover 10 and a limiting plate 902 protruding above the inclined slope 703, The limiting plate 902 limits the limit position of the pressure block 701 under the push of the driving mechanism, and the limit position is that the bottom surface of the pressure block 701 and the inclined slope 703 are completely attached. It can effectively prevent the pressure block from sliding too far, and through the complete fit of the pressure block and the cushion block, the force of the pressure rod on the explosion-proof cover is more direct and accurate, and the locking of the explosion-proof cover can be effectively realized.

[0035] In order to further lock the explosion-proof cover 10, preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com