Method and device for uniformly feeding continuous conveyor

A technology of conveyors and feeding devices, applied in the direction of conveyor control devices, transportation and packaging, conveyors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

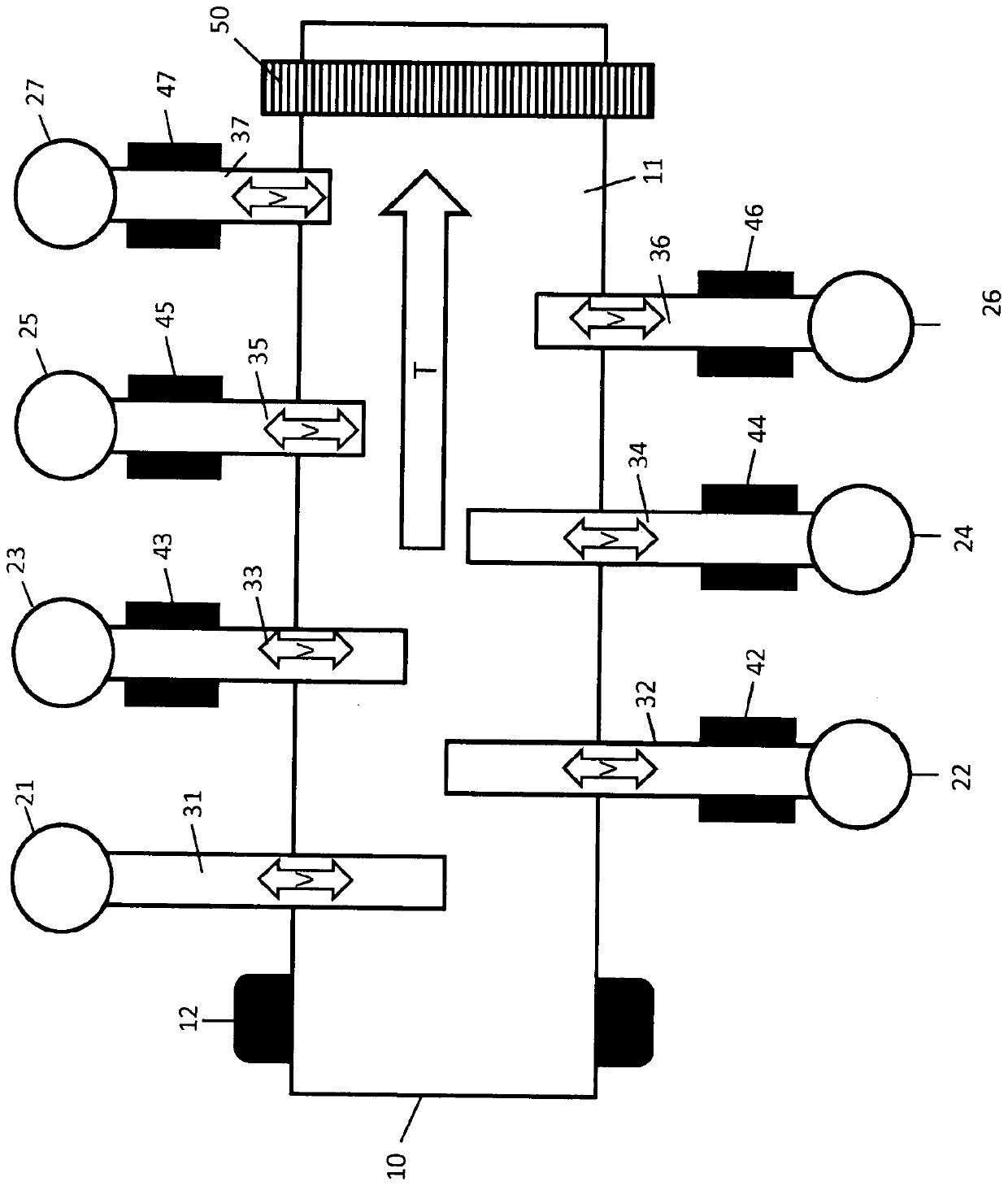

[0173] As shown, the continuous conveyor 10 may be a common conveyor belt which is operated in a rotating manner via at least one drive unit 12 so that the material to be transported is transported in the transport direction T. As shown in FIG. In this case, the material is applied to the carrier region 11 . Rolling screens are also conceivable as well as continuous conveyors of all the aforementioned types.

[0174] Production units 21 to 27 are units for performing upstream processing steps. Here, for example, they may be pelletizing disks for the production of green pellets of iron ore. From these production devices 21 to 27 further continuous conveyors 31 to 37 lead to the continuous conveyor 10 . They are designed such that at their ends they apply material on the continuous conveyor 10 . In the simplest form, this is achieved by the fact that these continuous conveyors 31 to 37 are designed as conveyor belts which, at the position of their corresponding discharge pull...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap