A component and bearing disassembly tool

A technology for bearings and components, which is applied in the field of components and bearing disassembly tools, and can solve problems such as inability to implement bearing disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

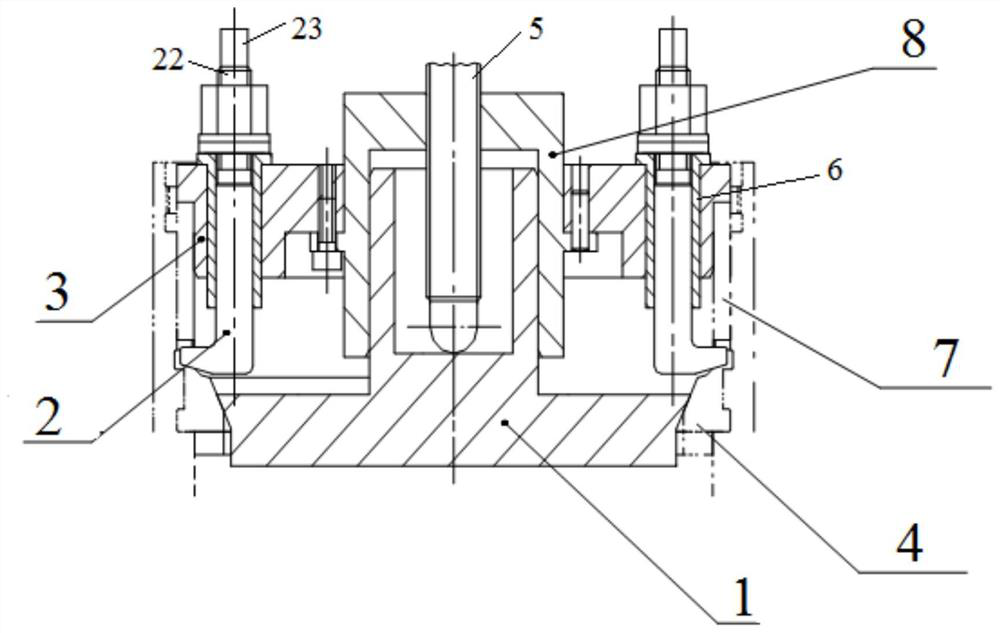

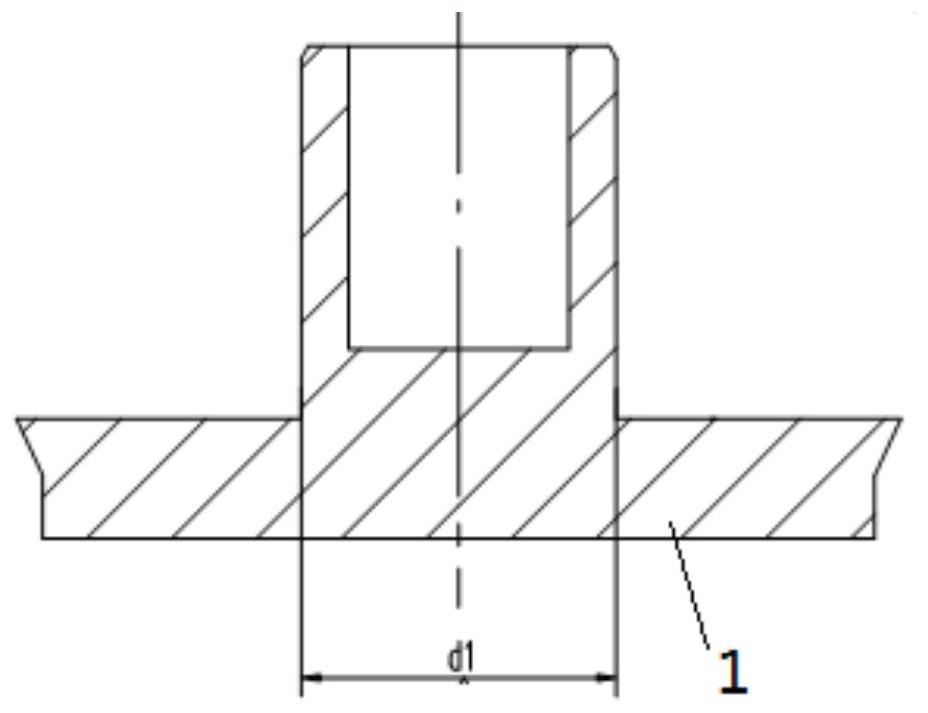

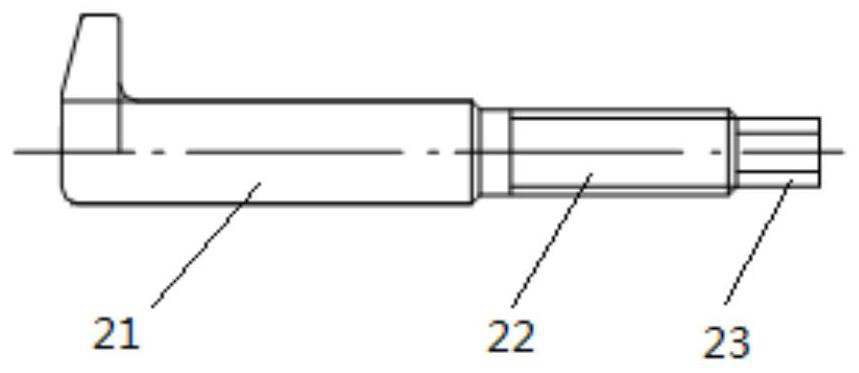

[0029] Such as figure 1 As shown, the high-pressure rotor assembly bearing disassembly tool designed by the present invention based on the principle of split-body combination and ring-to-ring interlocking includes a base plate 1, a support plate 3, a bushing 8 and a part adjustment pad 4; the base plate 1 is disc-shaped, and its There is a boss in the center, a blind hole is opened in the middle of the boss, and the lower end of the bottom plate 1 is provided with a conical profile, which is offset against the conical profile inside the part adjustment pad 4; the bushing 8 is set on the On the boss, the bushing 8 is cylindrical, and the top center of the bushing 8 is provided with a threaded hole, and a driving bolt 5 is arranged in the threaded hole; 3 is provided with a connecting portion, and the two are connected by bolts; the support plate 3 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com