Hub orienting and light-emitting vehicle logo

A car logo and wheel hub technology, which is applied in the field of auto parts, can solve the problems that the car logo cannot be seen clearly at night, the directional car logo cannot be illuminated, and the illuminated car logo cannot see the shape of the car logo. Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings of the description.

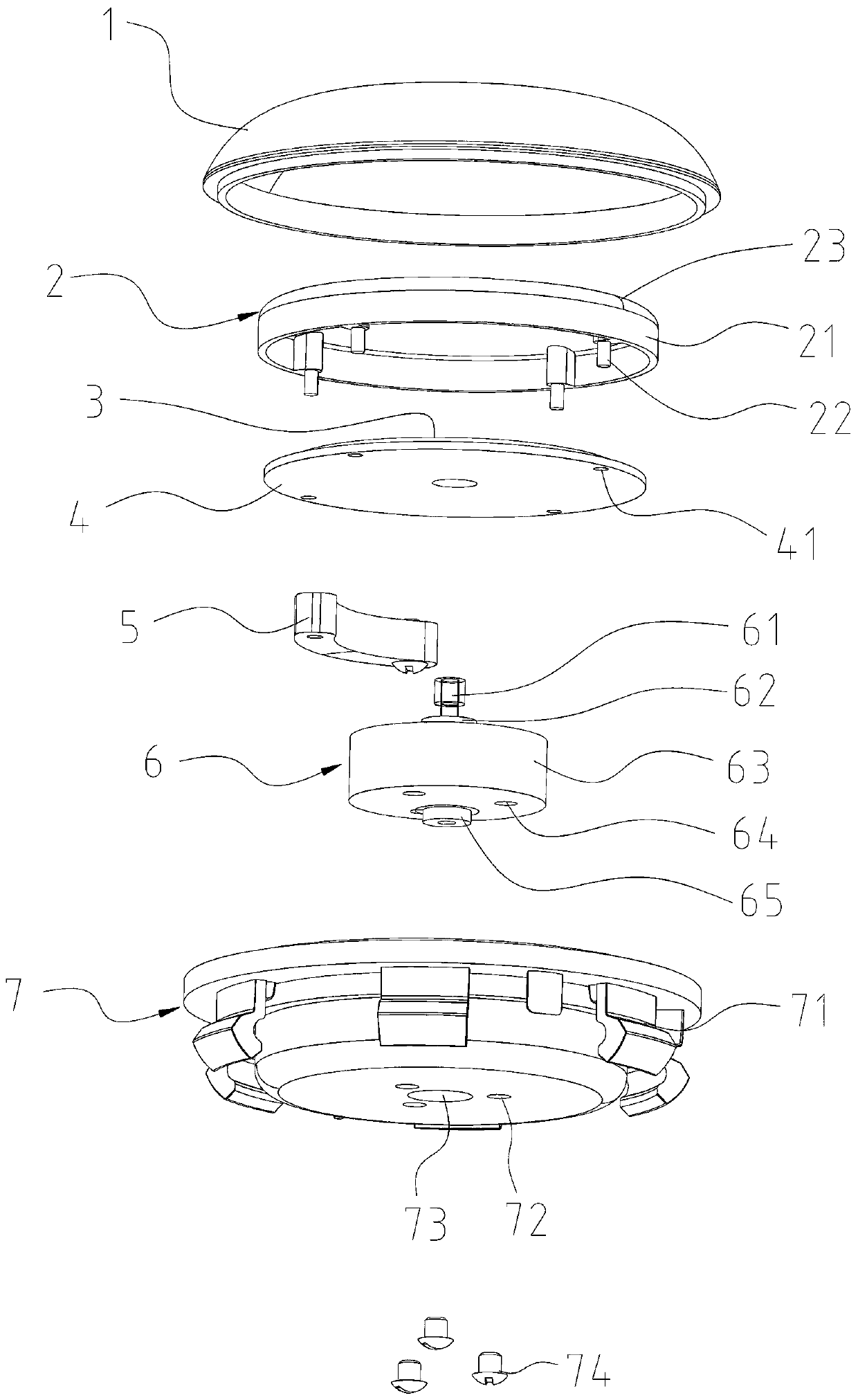

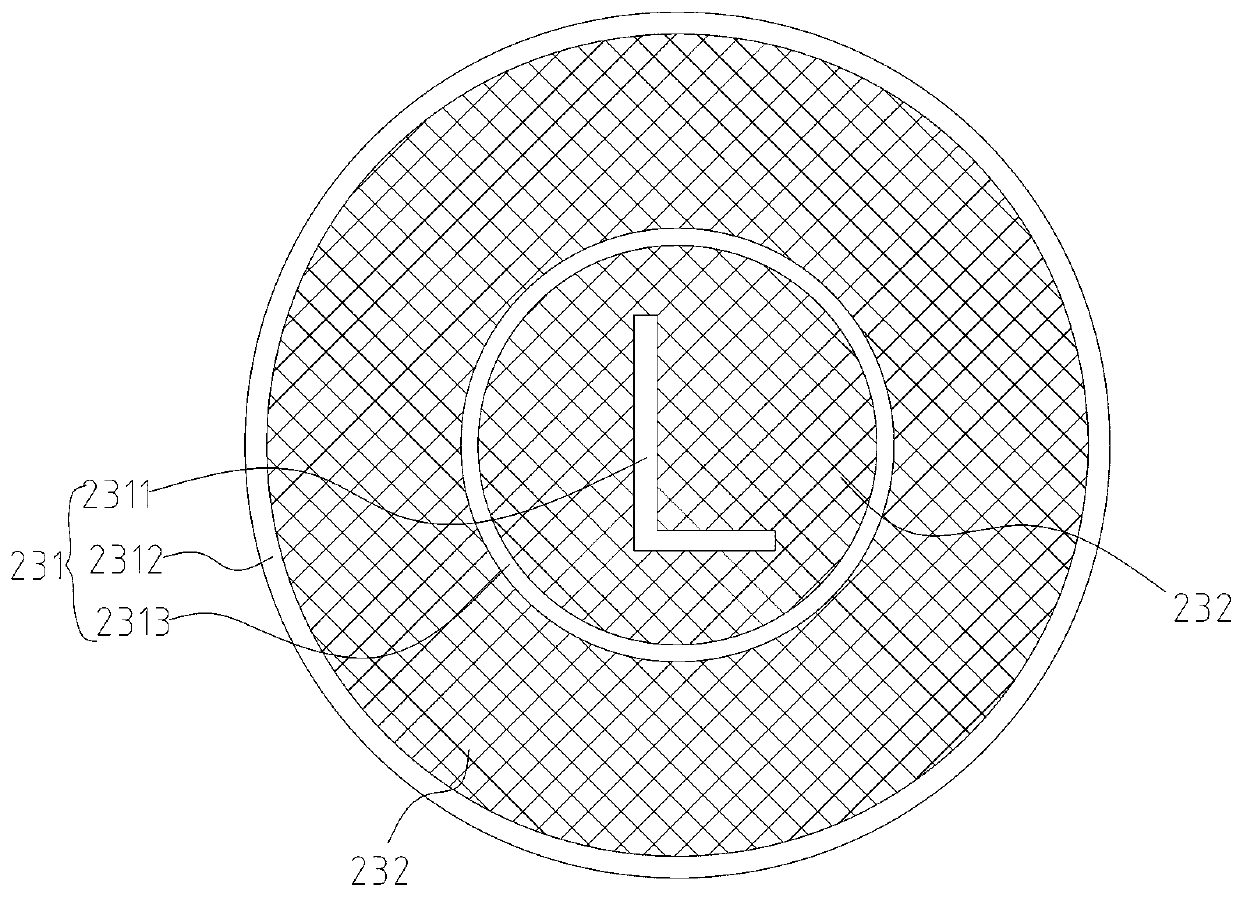

[0017] Such as figure 1 As shown, a wheel hub directional light-emitting car logo, a mounting plate 4, a counterweight 5, a lamp bead plate 3 arranged on the mounting plate 4, a decorative cover 2 covering the lamp bead plate 3, a base 7, and a base 7 The matching protective cover 1 and the outer rotor generator 6 that supplies power to the lamp bead board 3 . The protective cover 1 cooperates with the base 7 to form an accommodating cavity, and the decorative cover 2, counterweight 5, lamp bead board 3, mounting plate 4 and outer rotor generator 6 are arranged in the accommodating cavity. The protective cover 1 is a transparent part, and the joint between the protective cover 1 and the base 7 is provided with a sealing ring, so as to ensure that the parts in the accommodating cavity will not be affected by the external environment and prolong its s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com