Heat dissipating device, heat dissipating system and car

A technology of heat dissipation device and heat exchange device, which is used in heat exchange equipment, lighting and heating equipment, and coolant flow control, etc. The effect of uneven heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

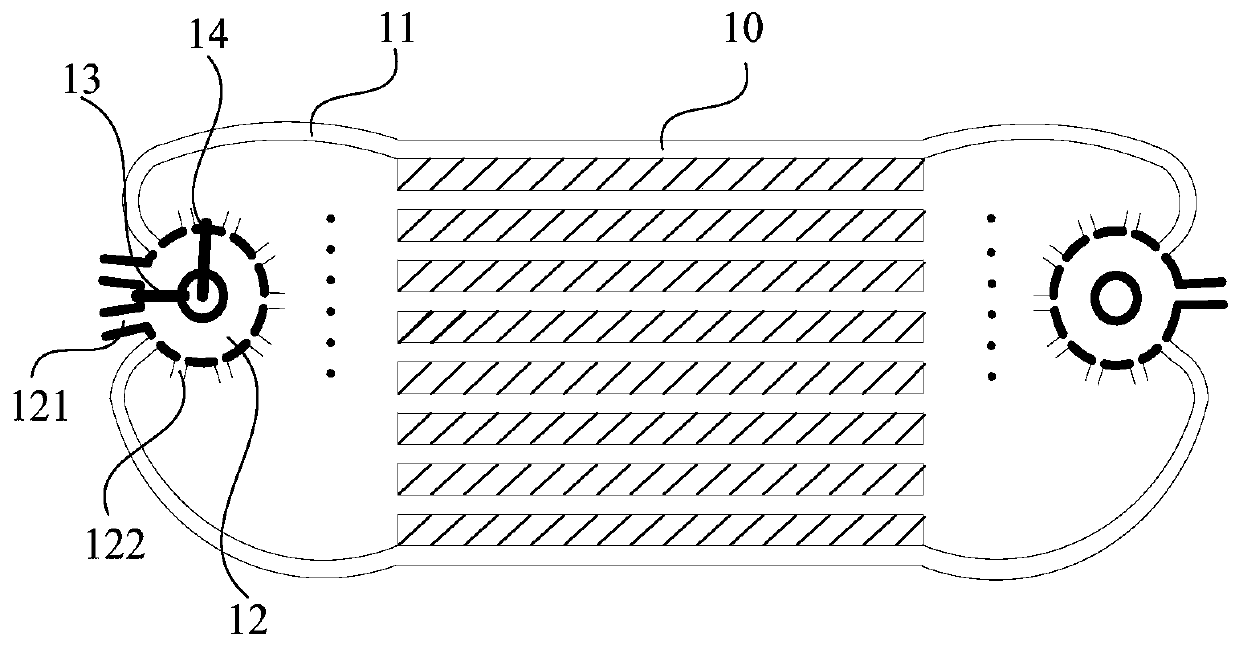

[0058] Such as figure 1 As shown, there is one multi-way valve 12, the first ports 121 of the multi-way valve 12 are respectively connected to the outlets of the cooling pipelines of the heating devices, and the second ports 122 of the multi-way valve 12 are respectively connected to the inlets of the heat pipes 10 , the outlet ends of the heat pipes 10 are respectively connected to the inlets of the cooling pipelines of the heat generating devices.

[0059] In the embodiment of the present application, the multi-way valve 12 is applied at the inlet of each cooling pipe 10, wherein the multi-way valve 12 is provided with two first ports 121 for liquid intake, and between the two first ports 121 A fixed partition 13 is set; a plurality of second ports 122 are set for liquid outlet, and a movable partition 14 is set between a plurality of second ports 122, and the second port 122 communicates with the heat dissipation pipe 10 through the connecting pipe 11, thereby Cooling liqu...

Embodiment 2

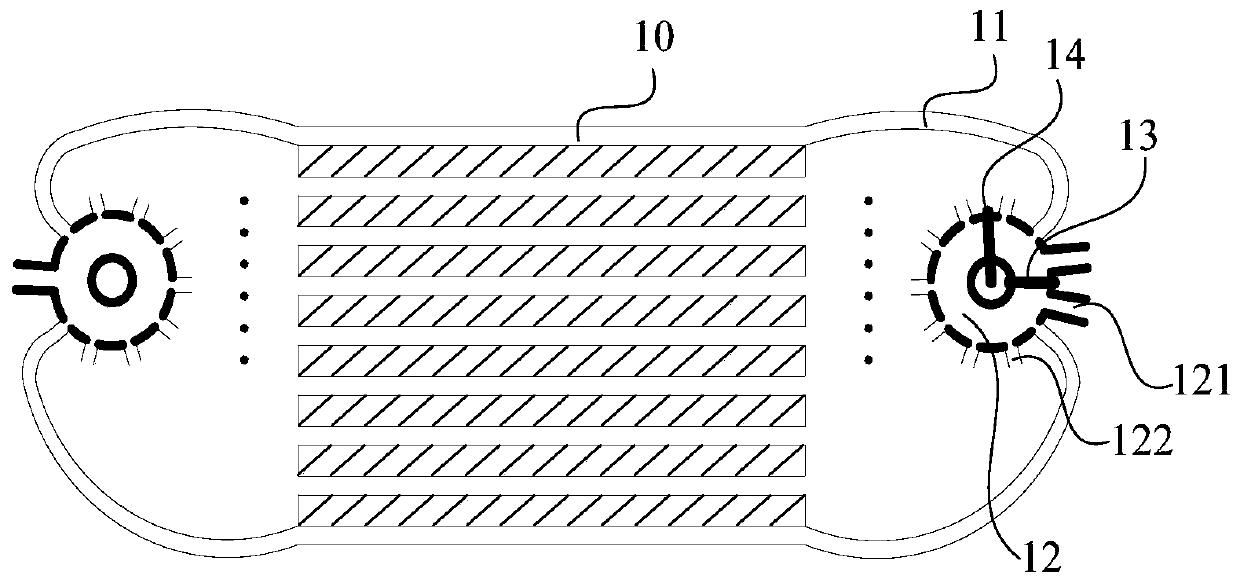

[0062] Such as figure 2 As shown, there is one multi-way valve 12, the first ports 121 of the multi-way valve 12 are respectively connected to the inlets of the cooling pipelines of the heating devices, and the second ports 122 of the multi-way valve 12 are respectively connected to the outlets of the cooling pipes 10 , the inlet ends of the heat pipes 10 are respectively connected to the outlets of the cooling pipelines of the heat generating devices.

[0063] In the embodiment of the present application, the multi-way valve 12 is applied at the outlet of each heat dissipation pipe 10, wherein the multi-way valve 12 is provided with two first ports 121 for liquid outlet, and between the two first ports 121 A fixed partition 13 is set; a plurality of second ports 122 are set for liquid intake, and a movable partition 14 is set between a plurality of second ports 122, and the second port 122 communicates with the heat dissipation pipe 10 through the connecting pipe 11, thereby...

Embodiment 3

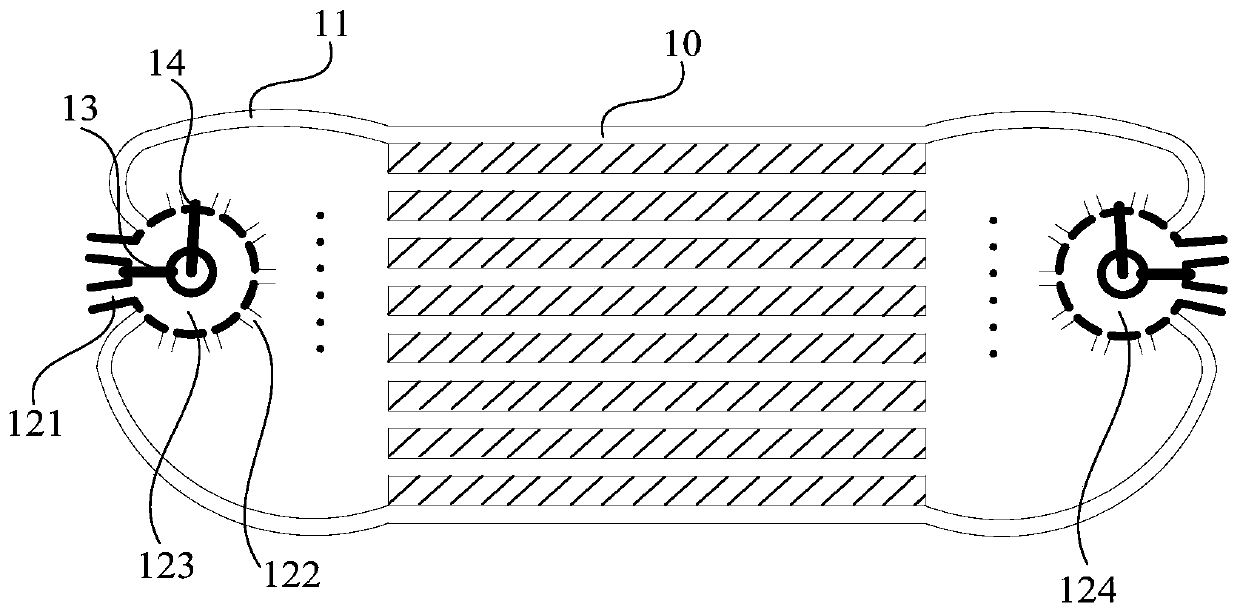

[0065] Such as image 3 As shown, there are two multi-way valves, namely the first multi-way valve 123 and the second multi-way valve 124;

[0066] The first port 121 of the first multi-way valve 123 is connected with the outlet of the cooling pipeline of each heat-generating device respectively, and the second port 122 of the first multi-way valve 123 is connected with the inlet of each radiating pipe 10 respectively, and each radiating pipe 10 The outlet ports are respectively connected to the inlets of the cooling pipelines of the heating devices;

[0067] The first port 121 of the second multi-way valve 124 is connected with the inlet of the cooling pipeline of each heat-generating device respectively, and the second port 122 of the second multi-way valve 124 is connected with the outlet of each radiating pipe 10 respectively, and the outlet of each radiating pipe 10 The inlet ports are respectively connected to the outlets of the cooling pipelines of the heating devices;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com