Wave simulation test device of ship model

A technology for simulating testing and waves, which is applied in the field of ship model wave simulating test devices, can solve the problems of inclined dragging and sensor range should not be too large, and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

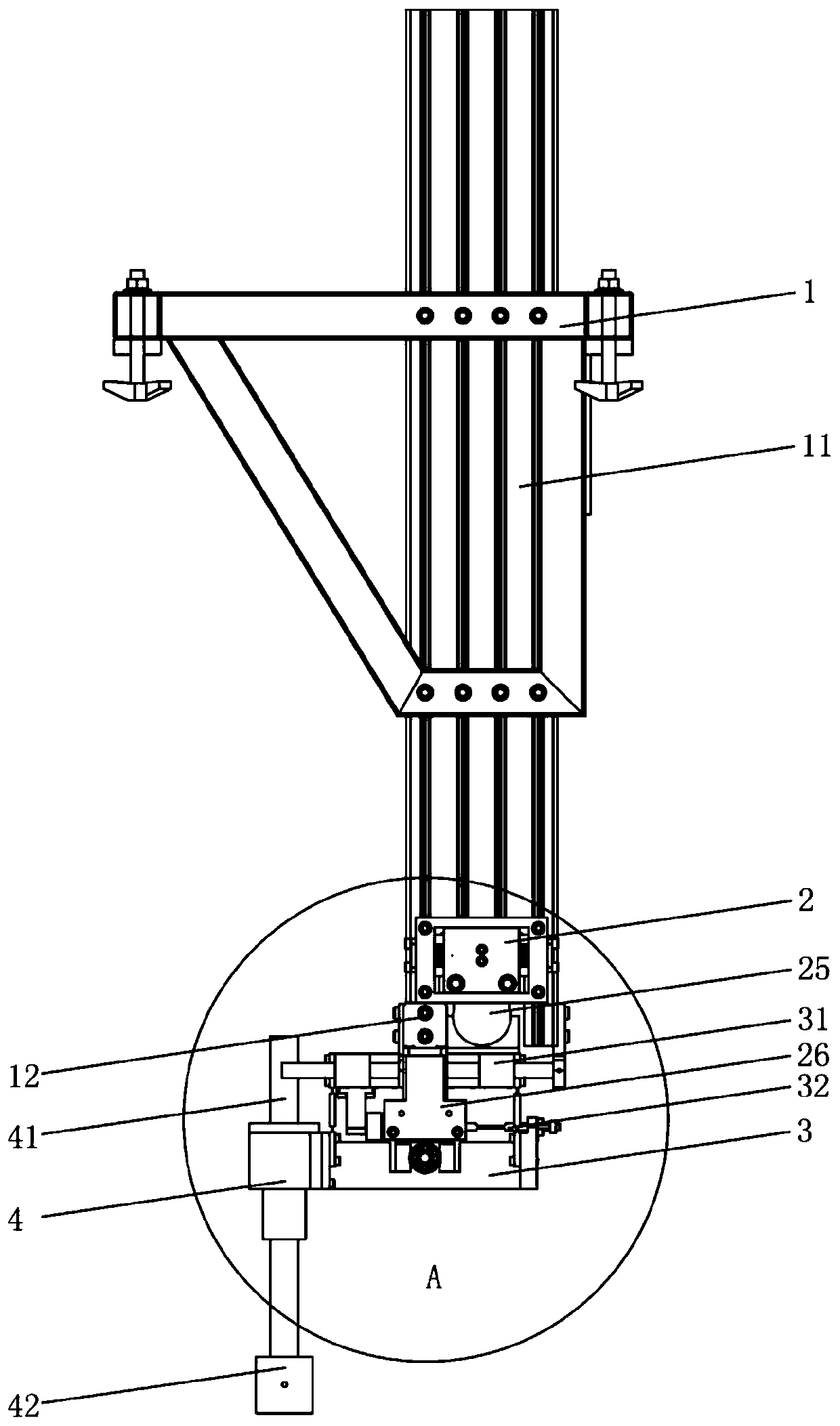

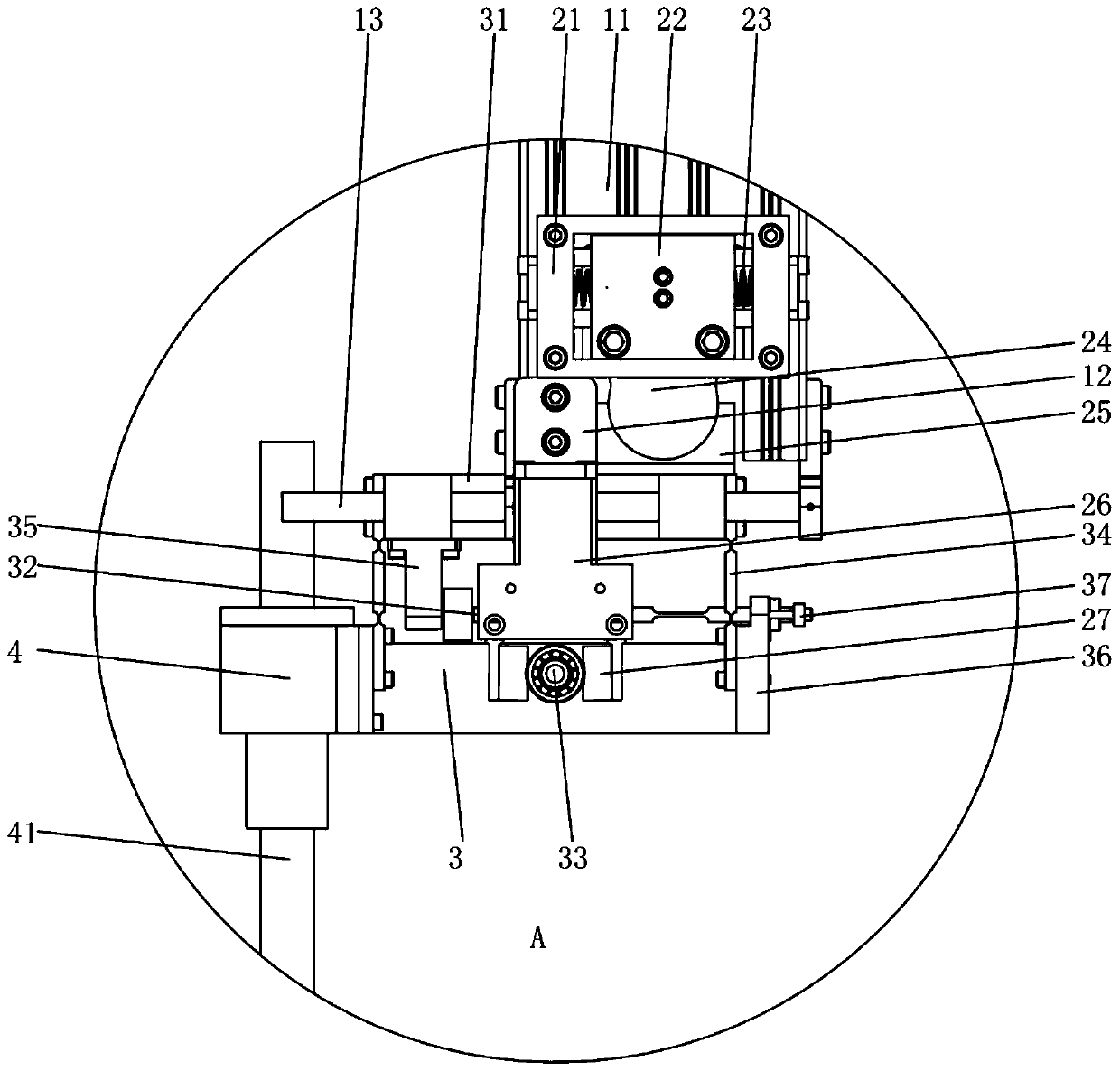

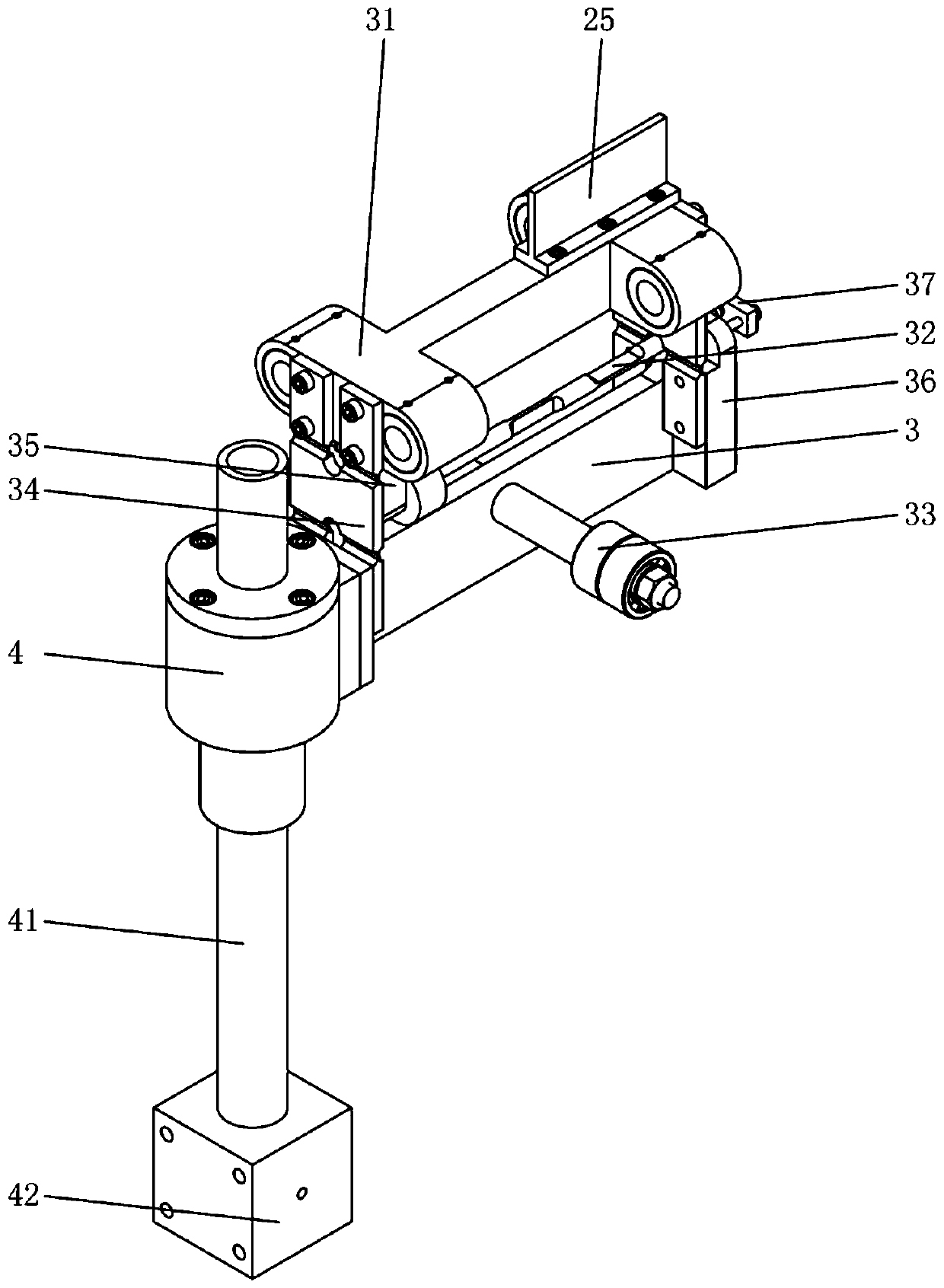

[0019] Such as figure 1 As shown, a ship model wave simulation test device according to the present invention includes a towing fixture 1, a bearing column 11, a differential block 31 and a force transmission member 3, and the bearing column 11 is vertically arranged and connected to the towing The fixed frame 1 is connected, and the lower end of the load-bearing column 11 is provided with a buffer 2 and a slide bar support 12; the slide bar support 12 is provided with a transverse slide bar 13, and the differential block 31 is connected to the transverse slide bar 13 through a linear bearing. The force transmission member 3 is arranged at intervals below the differential block 31 and is connected with it, and a tension sensor 32 is arranged between the differential block 31 and the force transmission member 3; between the buffer 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com