Equipment performance test device and method capable of simulating mine complex coupling environment

A technology for equipment performance and inspection devices, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of single inspection items, different aging speeds of equipment, and affecting normal work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below.

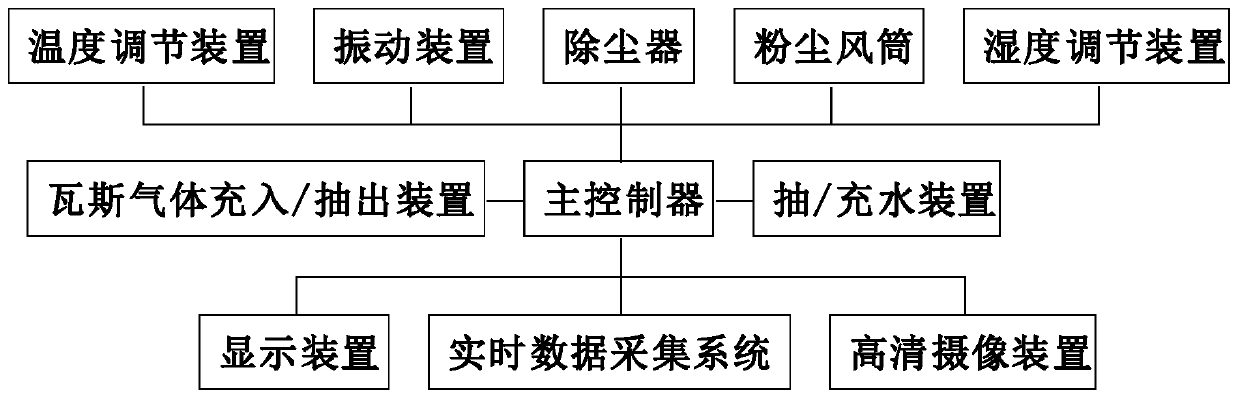

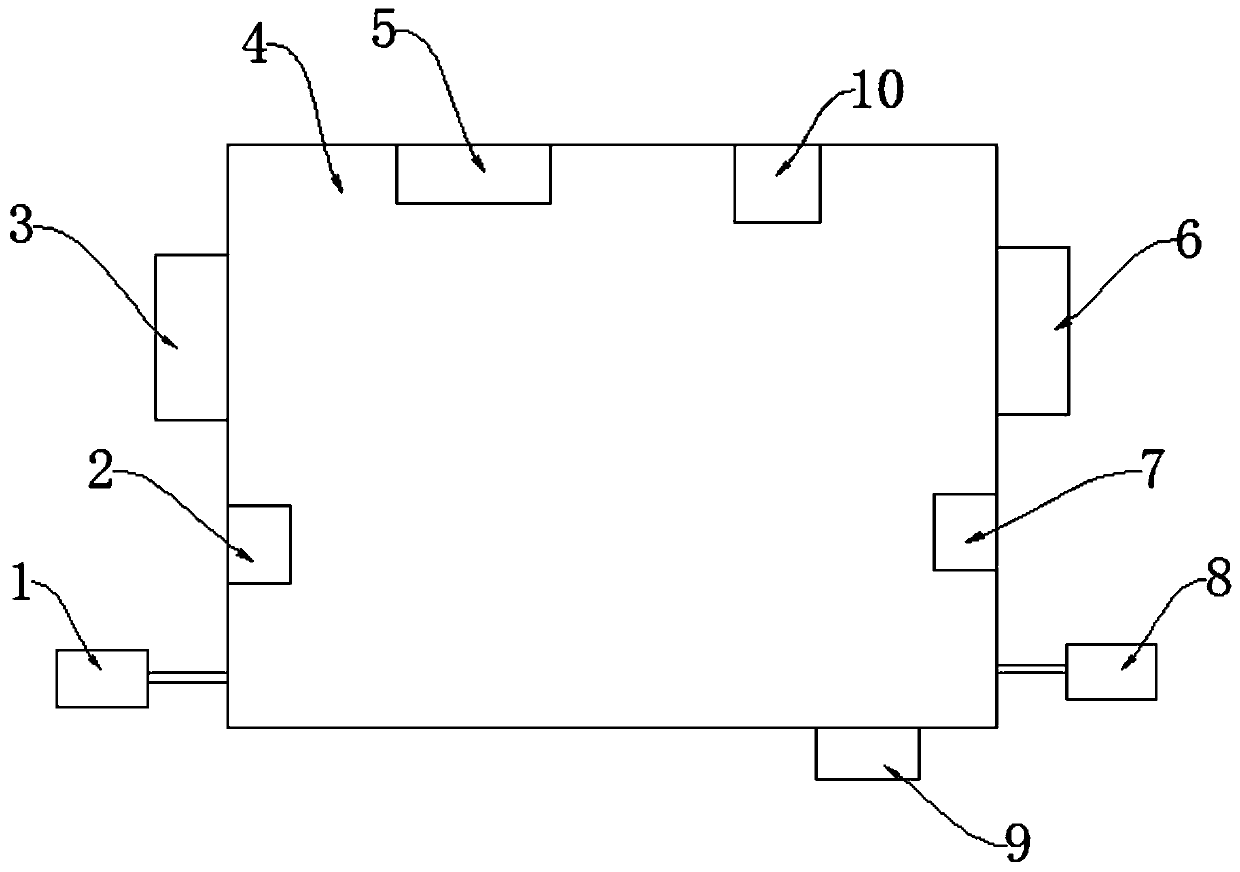

[0037] As shown in the figure, an equipment performance inspection device capable of simulating the complex coupling environment of a mine, including a test chamber 4, a real-time data acquisition system 5, a main controller, a vibration device 9, a dust blower 6, a dust collector 3, and a humidity adjustment device 2. Temperature adjustment device 7, high-definition camera device 10, display device, gas filling / extracting device 1 and pumping / water filling device 8,

[0038] The vibration device 9 is fixed on the outside of the test box 4 for adjusting the vibration state of the test box 4;

[0039] The dust blower 6 communicates with the test box 4, and is used to fill the test box 4 with dust;

[0040] The dust remover 3 communicates with the test chamber 4 for removing the dust in the test chamber 4;

[0041] Described humidity adjustment device 2 is fixed in the test box 4, is used for regulating the humidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com