Testing method for evaluating working performance of self-compacting concrete

A self-compacting concrete and work performance technology, applied in the field of concrete, can solve the problems of not being able to fill the horizontal grooves fully, not being able to simulate the actual working conditions well, and not considering the inhomogeneity problems such as self-compacting concrete segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0043] 1. According to the self-compacting concrete formula in Table 1, see Table 1, take the materials, and then put the materials into the concrete mixer together, stir for 60s, then add mixing water, and continue stirring for 180s to prepare fresh self-compacting concrete. use.

[0044] Two, a kind of test method for evaluating self-compacting concrete workability, it comprises the steps:

[0045] 1) Preparation of the NL-type pourability test device:

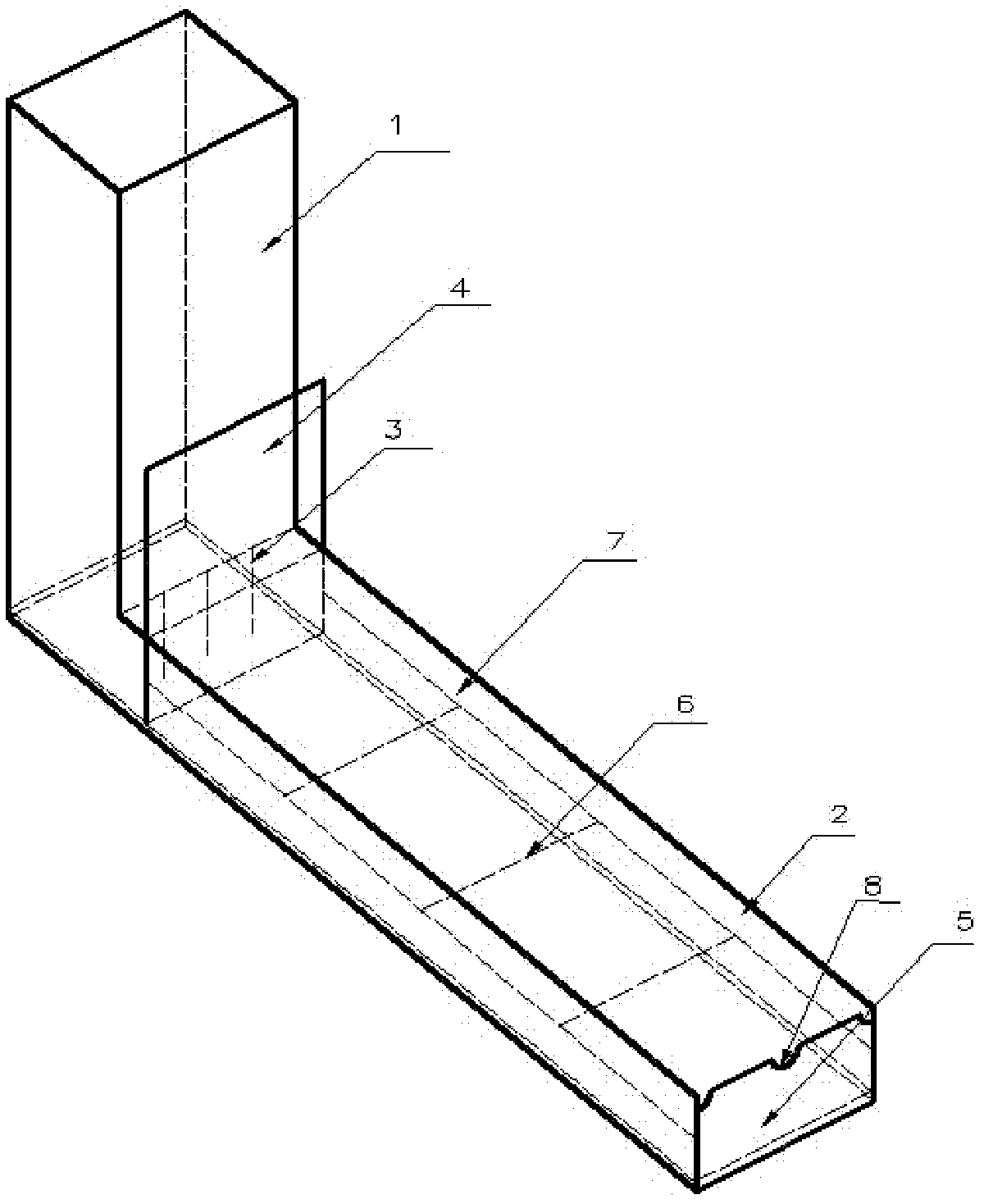

[0046] The NL-type pottability tester is an L-shaped box connected internally. The horizontal part of the L-shaped box is defined as a transverse groove (2). The inner cavity of the transverse groove is 1000mm long, 200mm wide, and 110mm high. A 10mm thick silicon-calcium board (5) is laid, and a vertical steel bar (3) composed of 3 steel bars side by side is arranged in the transverse groove and below the inner surface, and is 40mm from the right side of the inner side of the L-shaped box in the transverse groove A baffle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com