External corner mould reinforcing method

A technology of external angle and angle mold, which is applied in the direction of formwork/template/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, which can solve wasted materials and poor forming of external corners. and other problems, to achieve the effect of reducing costs, increasing supporting force, and reducing the probability of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

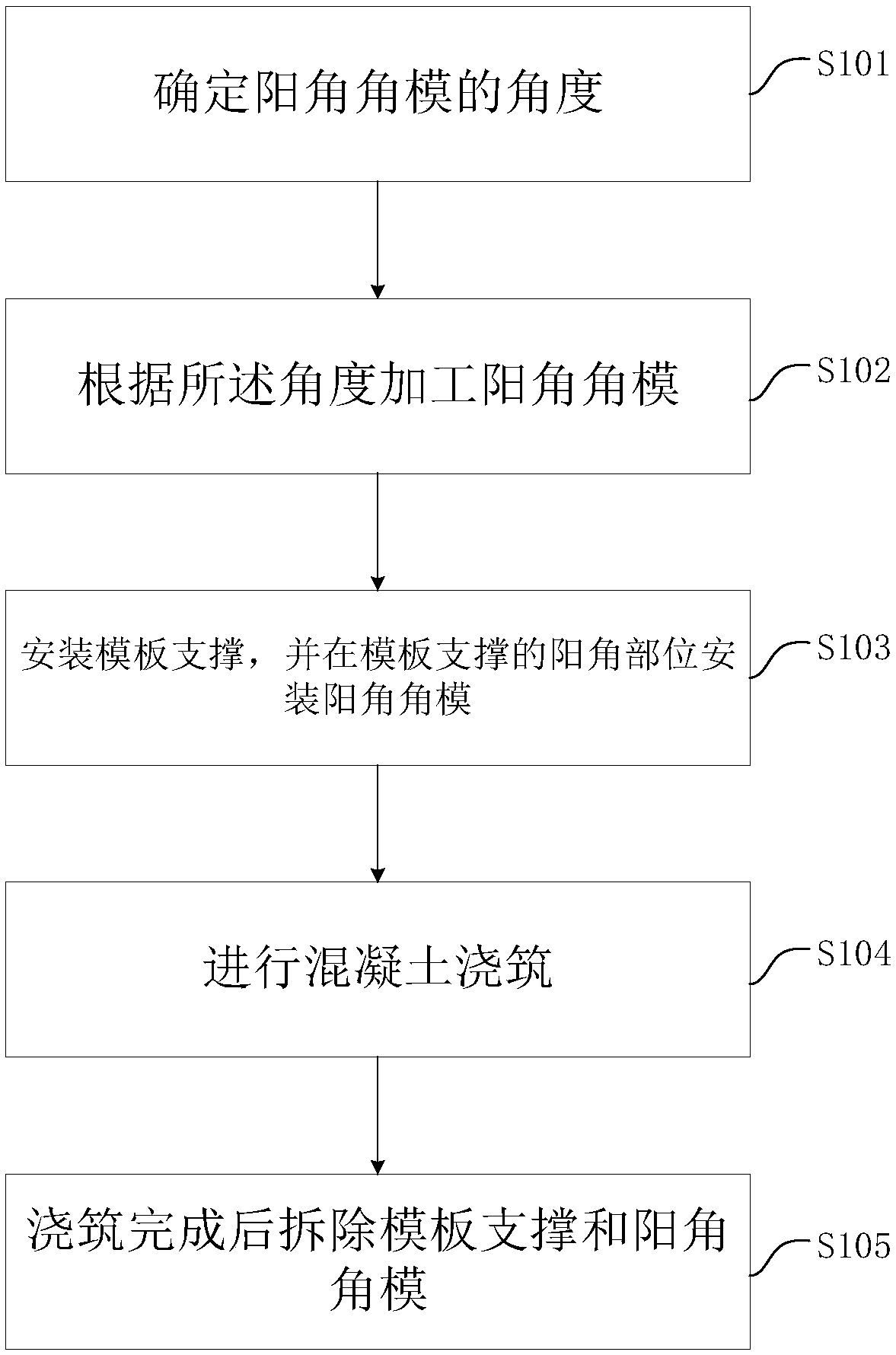

[0026] refer to figure 1 As shown, it is the first flow chart of the method for reinforcing the male corner formwork of the embodiment of the present invention. The steps of the method for reinforcing the external corner angle formwork described in this embodiment are:

[0027] S101 determining the angle of the male angle mold;

[0028] S102 processing the male angle mold according to the angle;

[0029] S103 install the formwork support, and install the external corner formwork on the external corner of the formwork support;

[0030] S104 Concrete pouring;

[0031] S105 After the pouring is completed, remove the formwork support and external corner formwork.

[0032] Specifically, S101 determines the angle of the male angle mold. Before starting to pour the pouring structure with the external angle, first determine the angle of the external angle, and determine the angle of the external angle formwork 1 according to the angle of the external angle. Among the beams, colu...

Embodiment 2

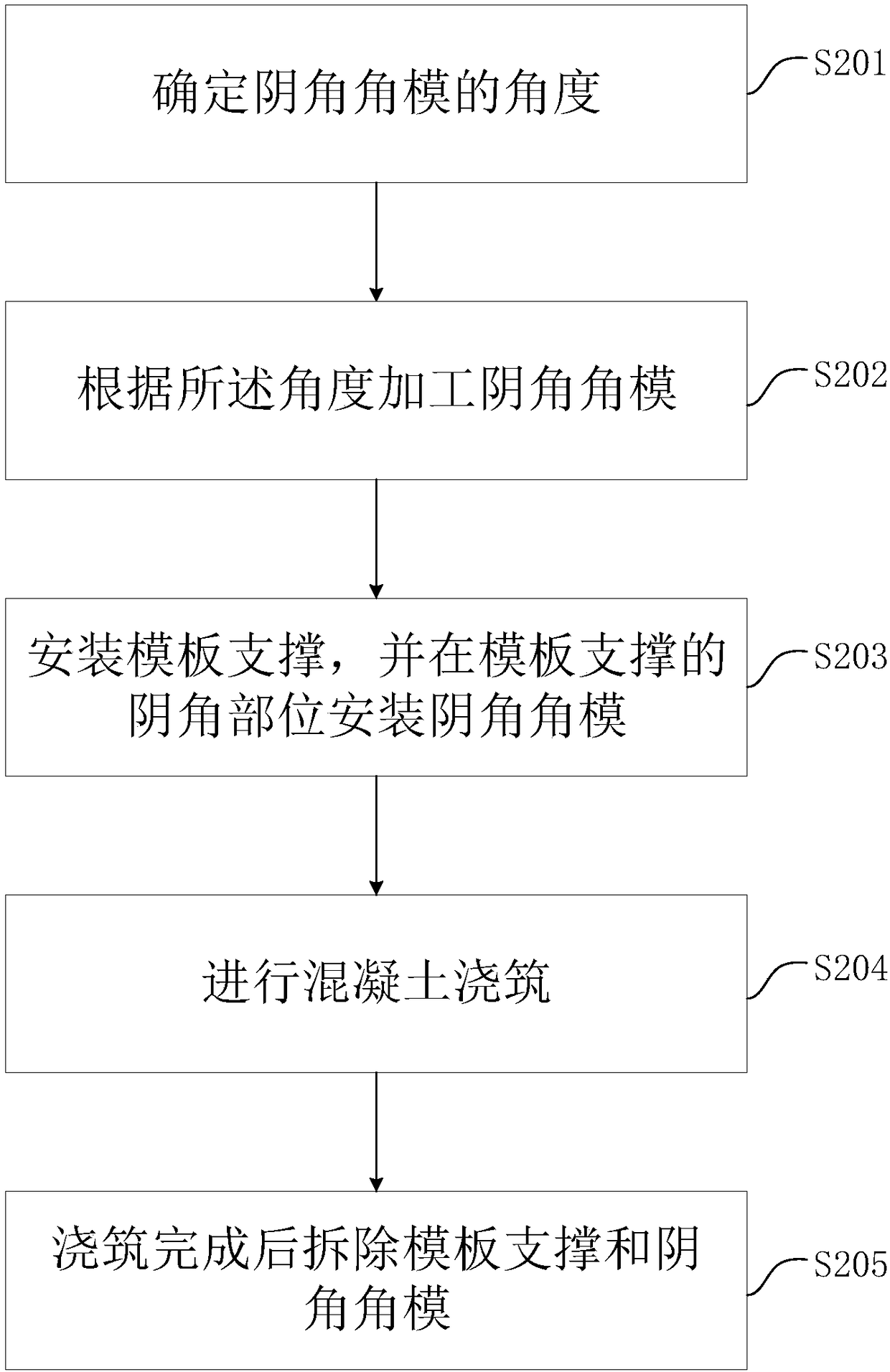

[0041] refer to figure 2 As shown, it is the second flow chart of the method for strengthening the male corner formwork of the embodiment of the present invention. It can be understood that the above construction techniques for external corners can also be applied to the construction of internal corners, and the implementation methods and steps are basically the same. Specifically, the steps applied to the construction of internal corners are as follows:

[0042] S201 determining the angle of the internal angle mold;

[0043] S202 processing the female angle mold according to the angle;

[0044] S203 Install formwork supports, and install internal corner molds at the internal corners of the formwork supports;

[0045] S204 Concrete pouring;

[0046] S205 After the pouring is completed, remove the formwork support and internal corner formwork.

[0047] Specifically, S201 determines the angle of the female corner mold. Before starting to pour the pouring structure with th...

Embodiment 3

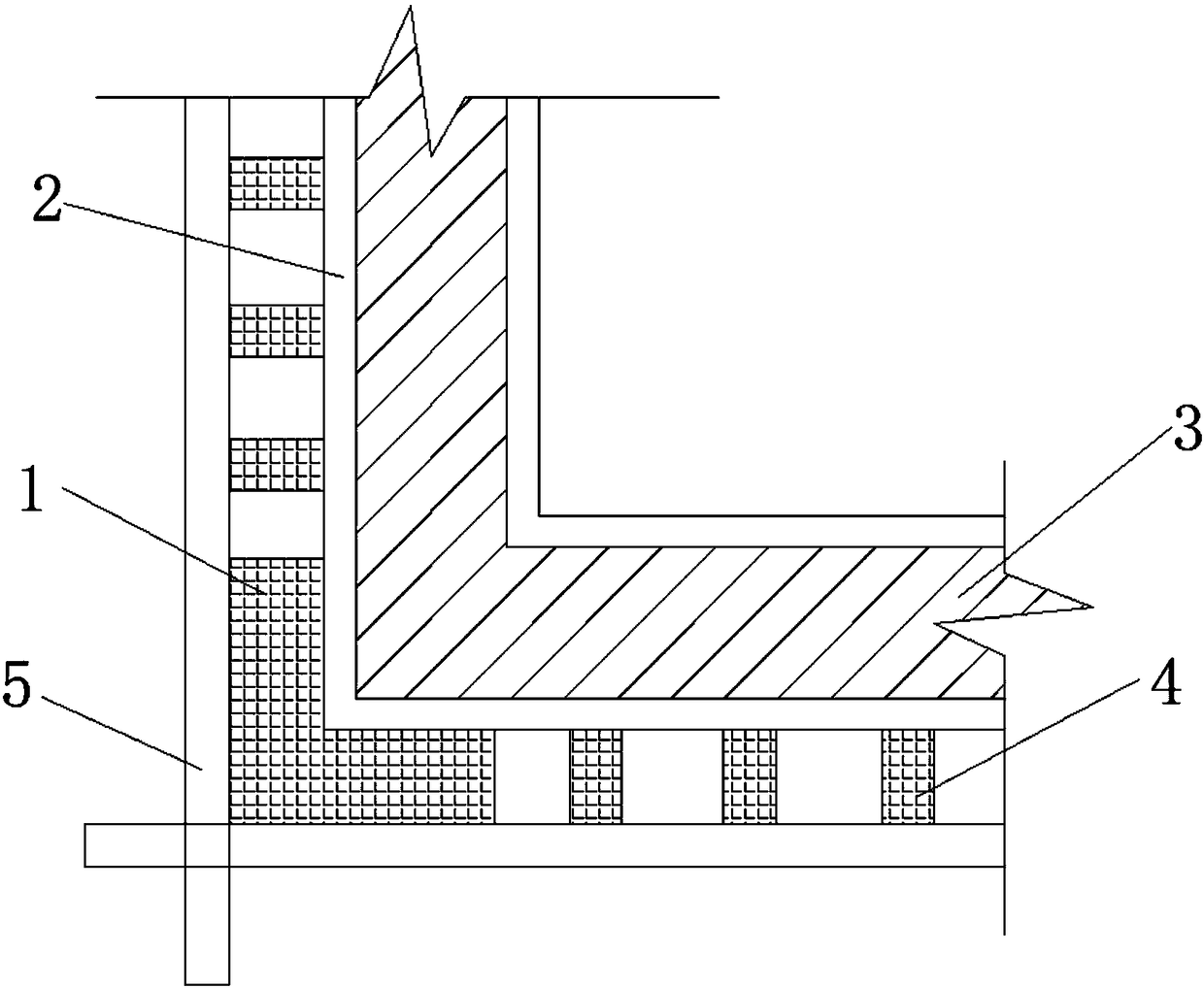

[0056] to combine image 3 and Figure 6 As shown, they are respectively the first cross-sectional schematic diagram and the first longitudinal cross-sectional schematic diagram of the method for strengthening the male corner corner form in the embodiment of the present invention. Specifically, after the male corner mold 1 is made, set the male corner template, and set the male corner mold 1 at the position of the male corner of the male corner template, and evenly set the vertical flute 4 and the horizontal flute on the side of the template 2 5 to fix the formwork 2 and the external corner angle mold 1. The formwork 2 is mainly used to form a blocking surface, and a plurality of formworks 2 cooperate to form a hollow structure for pouring concrete to form walls 3, beams and columns and other structures. The vertical flute 4 and the horizontal flute 5 are intersected to fix the formwork 2; the horizontal flute 5 cooperates with the corner formwork to fix the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com