Patents

Literature

72results about How to "Achieve high efficiency and energy saving effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic sintering fluxing agent

InactiveCN1974487ANo significant requirement on particle sizeLow priceCeramic sinteringSolid solution

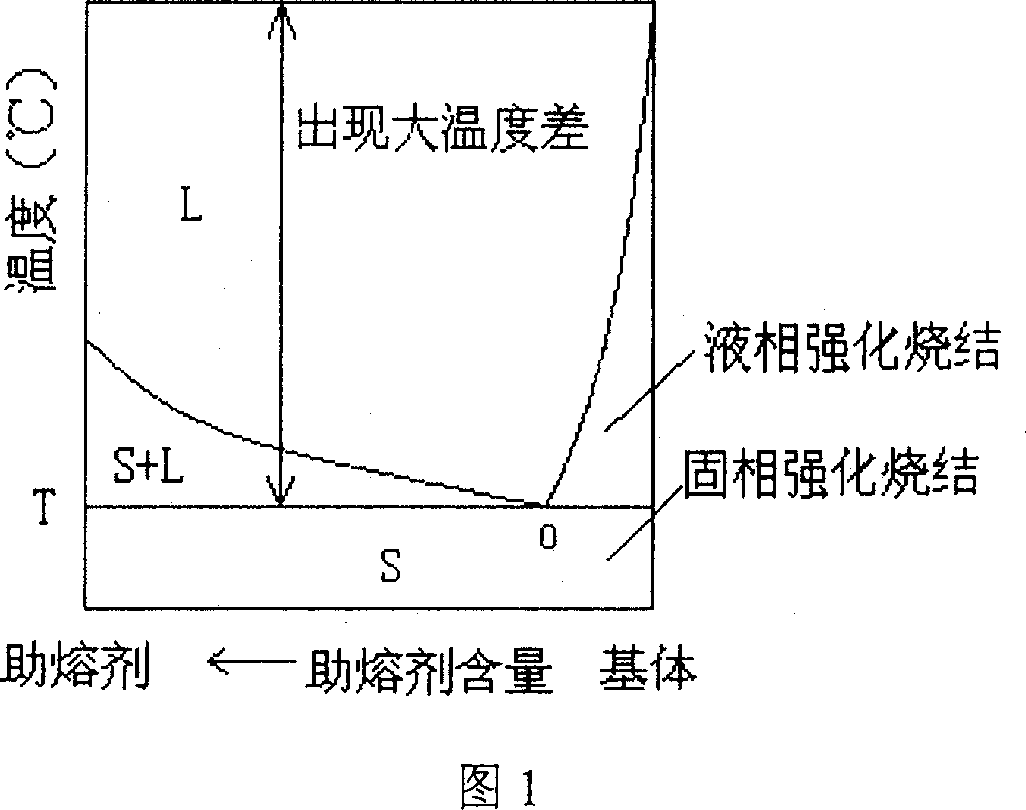

The present invention is ceramic sintering fluxing agent, and belongs to the field of building material technology. The method of the present invention is that the first level fluxing agent capable of generating solid solution of lower smelting point is used in fluxing the second level fluxing agent capable of generating solid solution of higher smelting point, the second level fluxing agent is used in fluxing the third level fluxing agent, and so on to complete the sintering of the material at relatively low temperature and lowered power consumption. The ceramic sintering fluxing agent of the present invention is a composite fluxing agent comprising B2O3, K2O+Na2O and CaF2 separately as the first level, the second level and the third level fluxing agent, or comprising Bi2O3, PbO and CaF2, or comprising V2O5, Bi2O3 and LiF+AlF3. It is added into sintering process in the amount of 0.01-0.5 % to lower the sintering temperature by 100 -170 deg.c.

Owner:UNIV OF SCI & TECH BEIJING

Linear constant-current controller, chip and driving device

ActiveCN102196643ALow costAchieve high efficiency and energy saving effectElectric light circuit arrangementEnergy saving control techniquesElectricityElectrical resistance and conductance

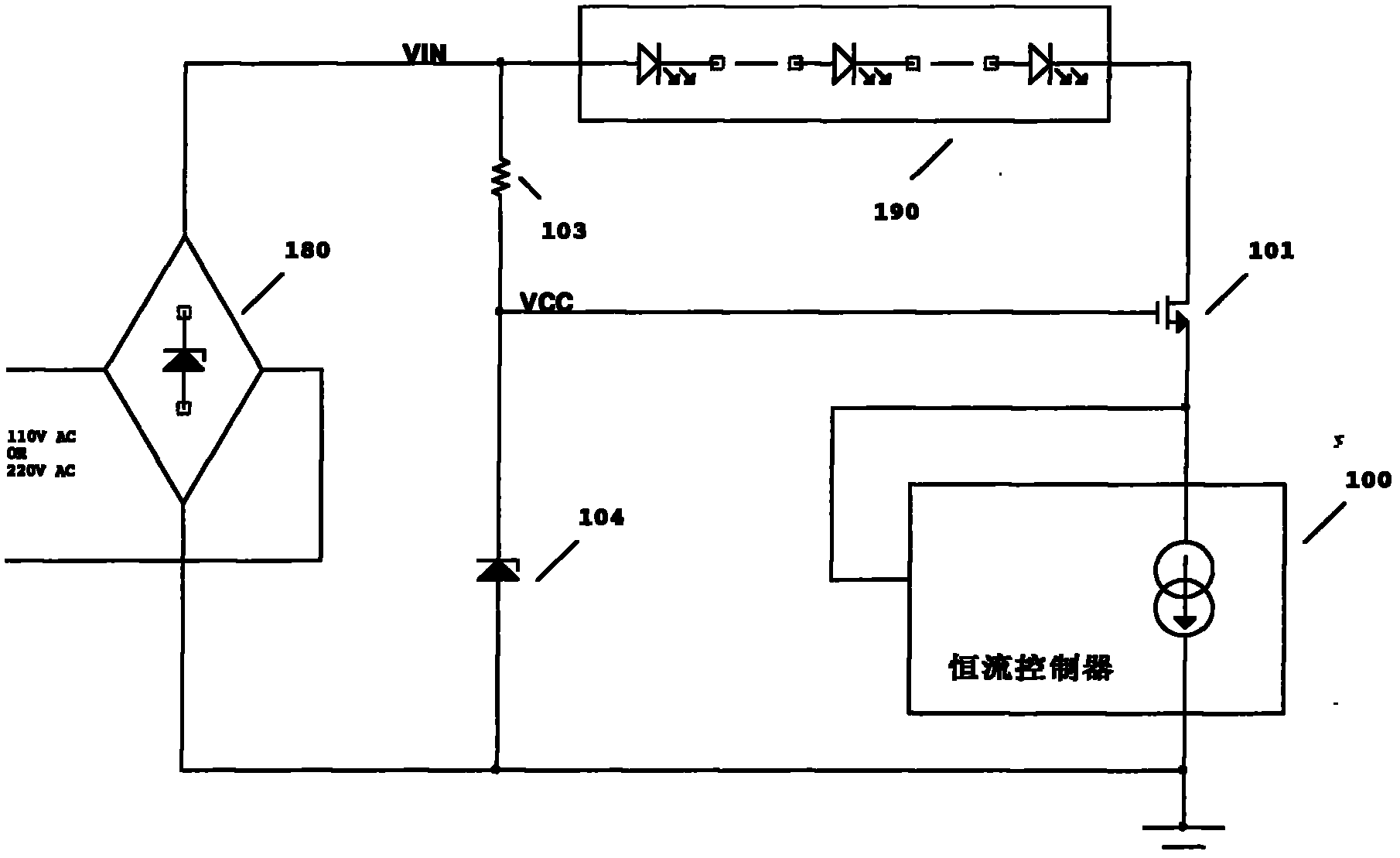

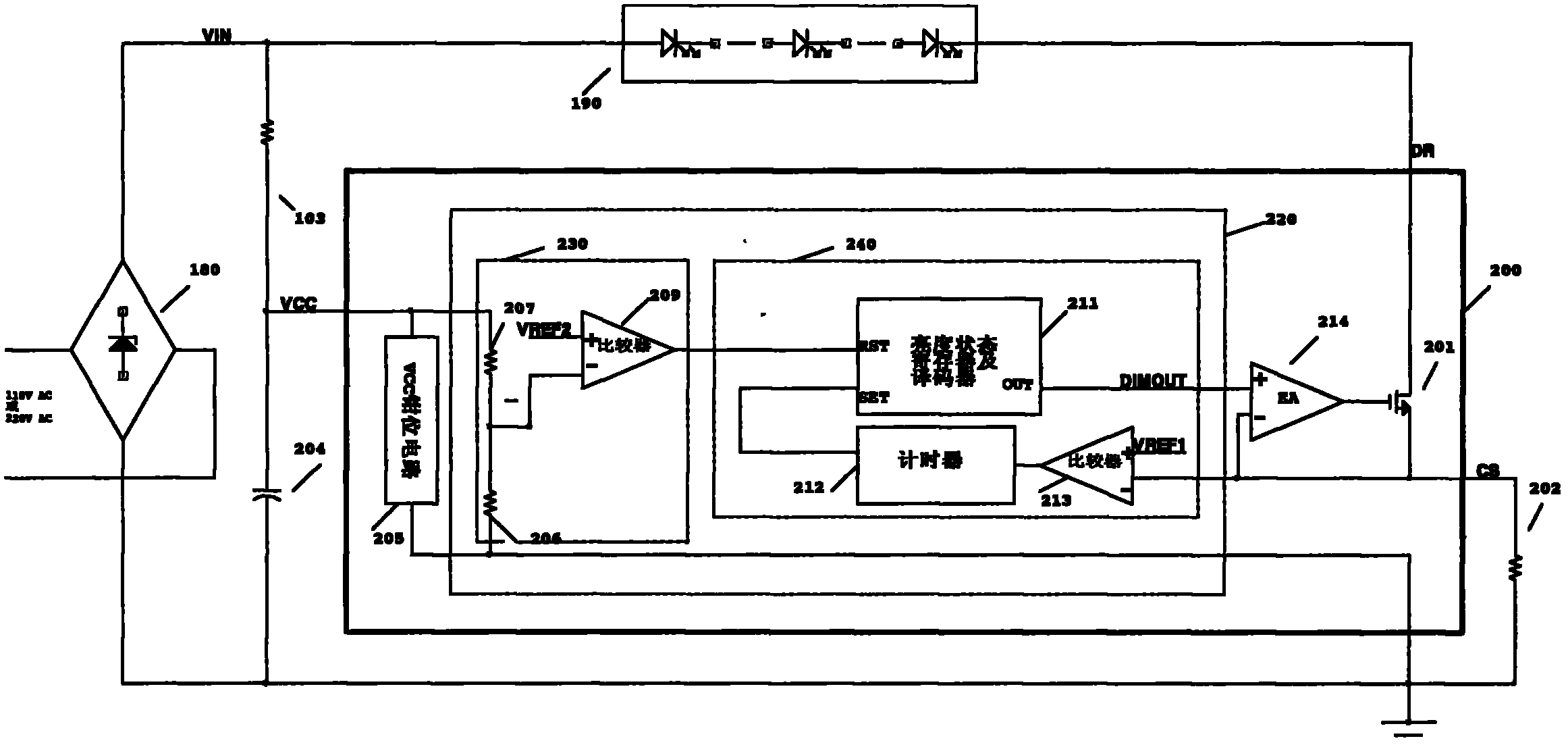

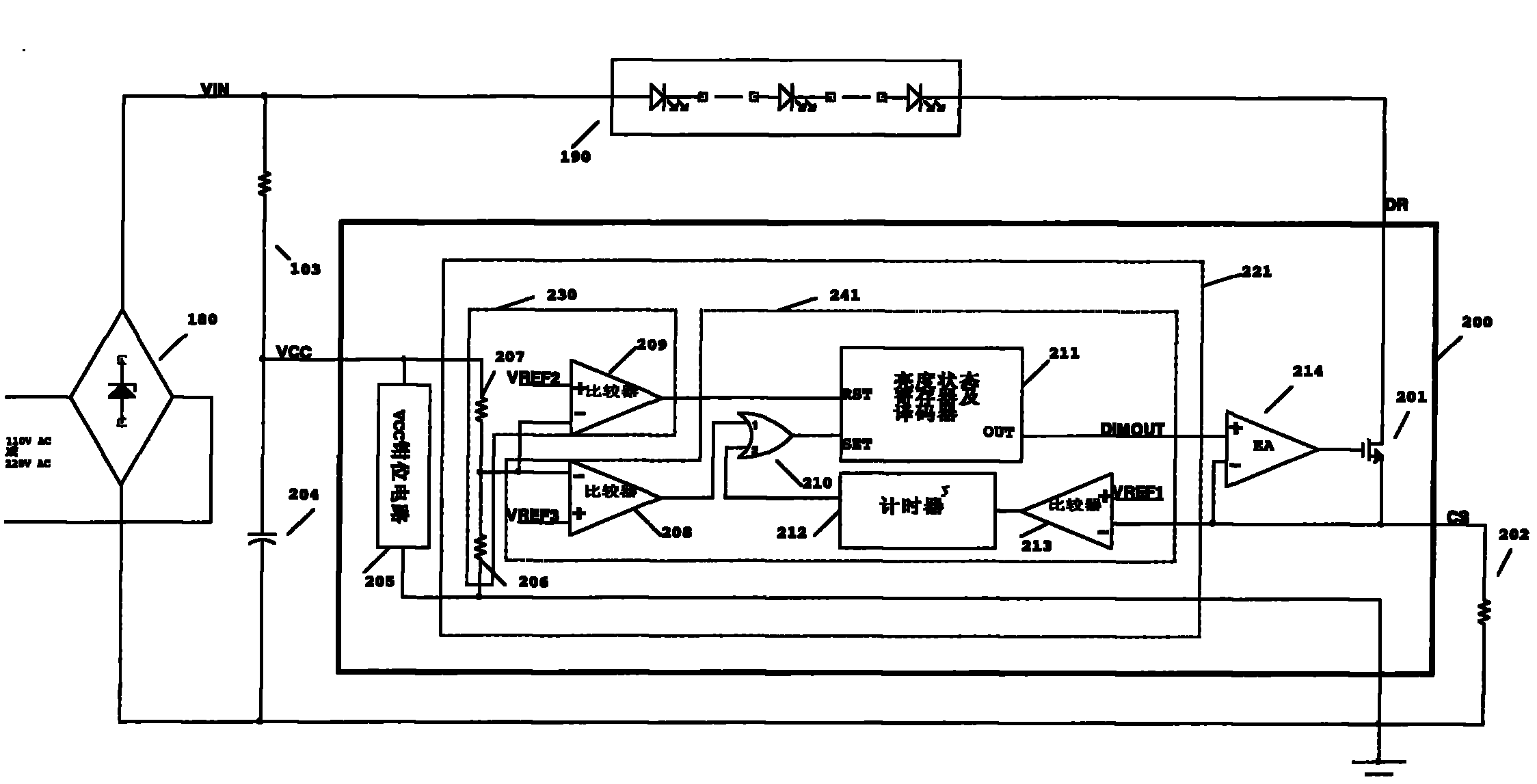

The invention discloses a linear constant-current controller, a chip containing the controller and a driving device, wherein a capacitor is connected between the power end of the controller and reference ground for supplying power for the controller under the state of power failure. The controller comprises a high-voltage MOS (metal oxide semiconductor) tube, an error amplifier and a dimming circuit, wherein the drain electrode of the high-voltage MOS tube is connected to an input voltage source by constant-current source load, and the source electrode is connected to the reference ground by a detection resistor; one input end of the error amplifier receives the detection signal of current flowing through the constant-current source load, the other input end receives a dimming signal, and the output end of the error amplifier is connected with the grid electrode of the high-voltage MOS tube; and the dimming circuit is used for generating the dimming signal when being electrified according to the current detection signal. The linear constant-current controller is characterized in that the resolution mechanism of the dimming function of a linear constant-current switch is realized according to the current detection signal, and energy can be effectively saved.

Owner:许瑞清

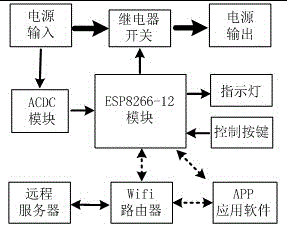

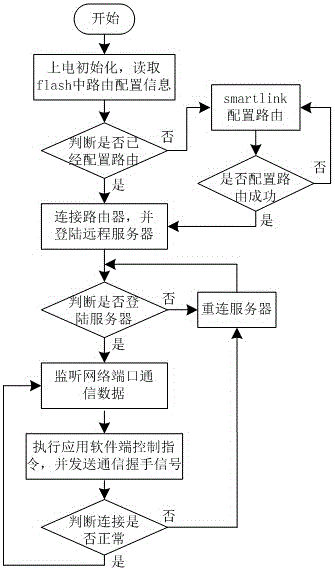

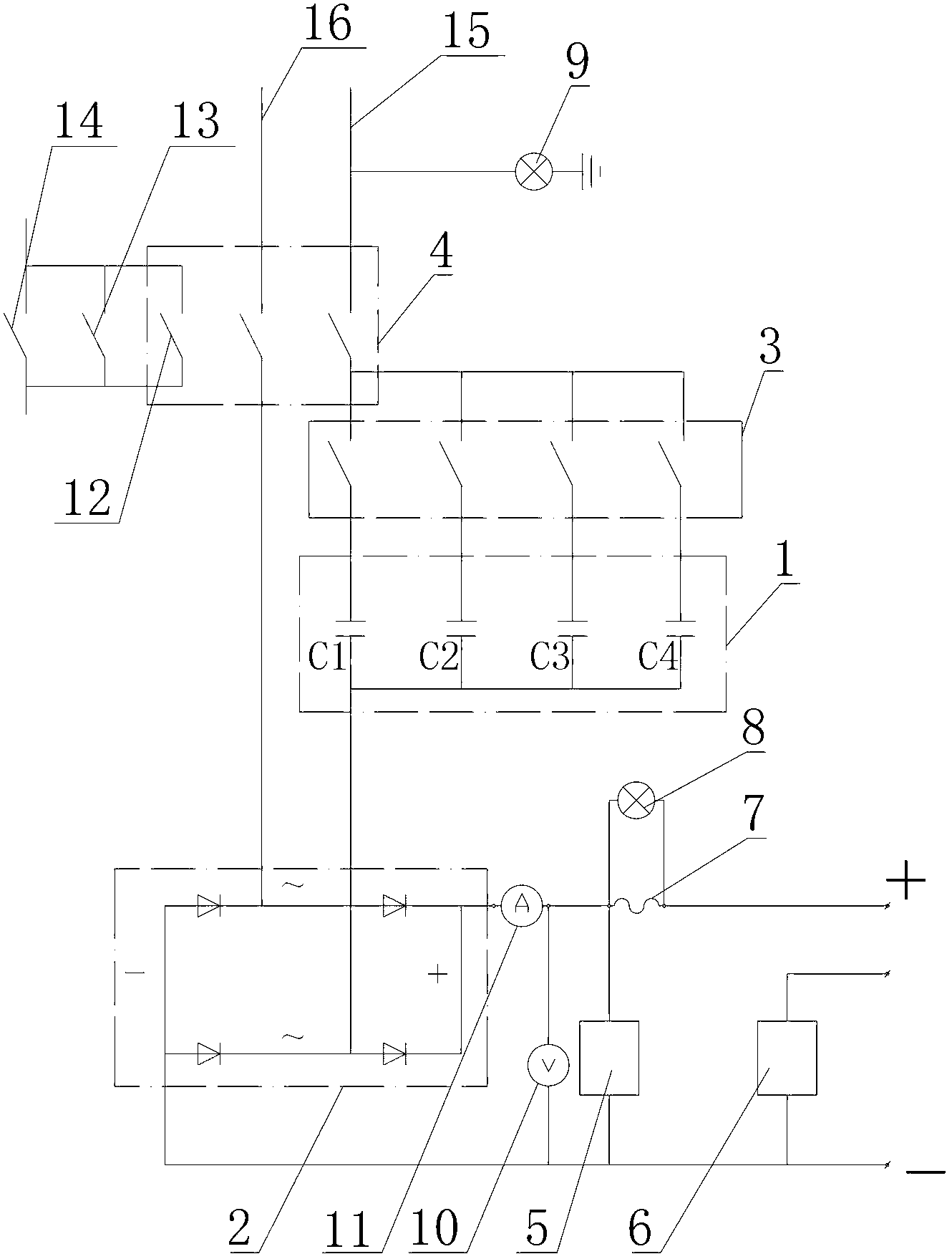

Intelligent socket and control method based on wireless wifi communication technology

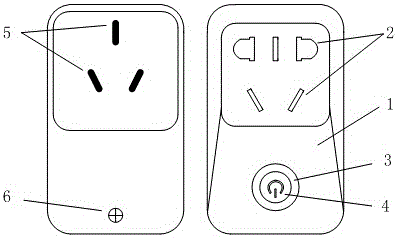

InactiveCN106159579AAchieve high efficiency and energy saving effectCoexistence manualProgramme controlComputer controlEngineeringPersonal computer

The invention relates to an intelligent socket and a control method based on the wireless wifi communication technology. The intelligent socket comprises a shell, a fixing screw hole, a controller, a power input part, a power output part, a relay switch, an ACDC module, an indicating light and a control key. The shell is provided with the fixing screw hole, power input pins are embedded in a bottom shell body of the shell, a five-jack standard socket is arranged at the upper end of a surface shell body of the shell and serves as the power output part, the control key and the double-color LED indicating light are arranged at the lower end of the surface shell body of the shell, the power input part is connected with the ACDC module and the relay switch, the relay switch is connected with the power output part, and the controller is connected with the relay switch, the ACDC module, the indicating light and the control key. The socket is remotely controlled on a mobile terminal such as an intelligent mobile phone or a tablet personal computer, common household appliances such as an electric fan, a water heater and an air conditioner can be changed into intelligent products and can be connected in series through the Internet to be controlled in a centralized mode, an energy-efficient effect can be achieved, and various demands of people in life can be met.

Owner:JIANGXI HONGDU AVIATION IND GRP

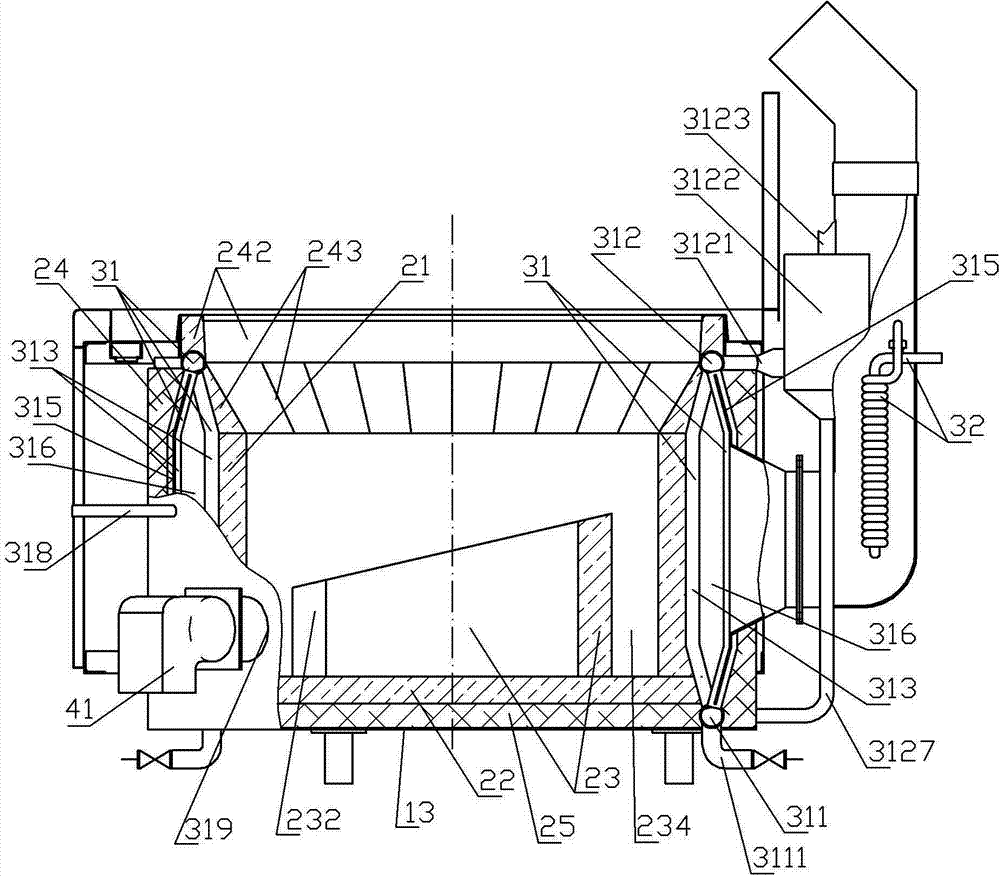

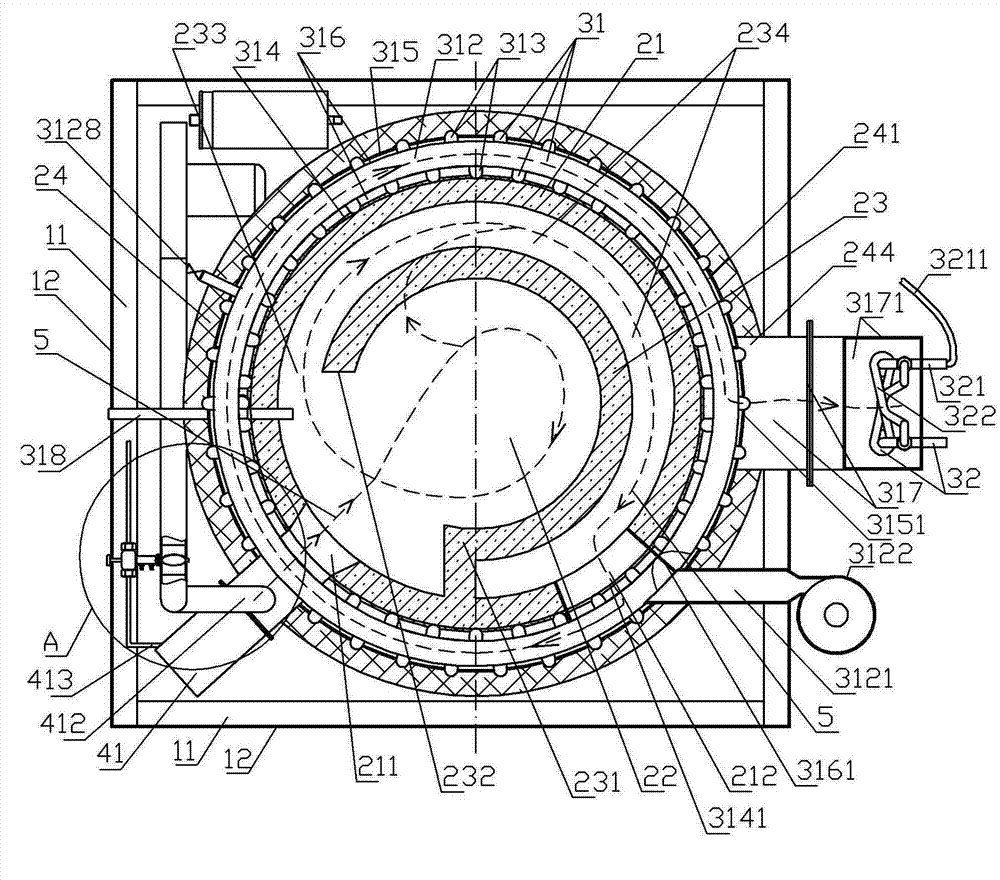

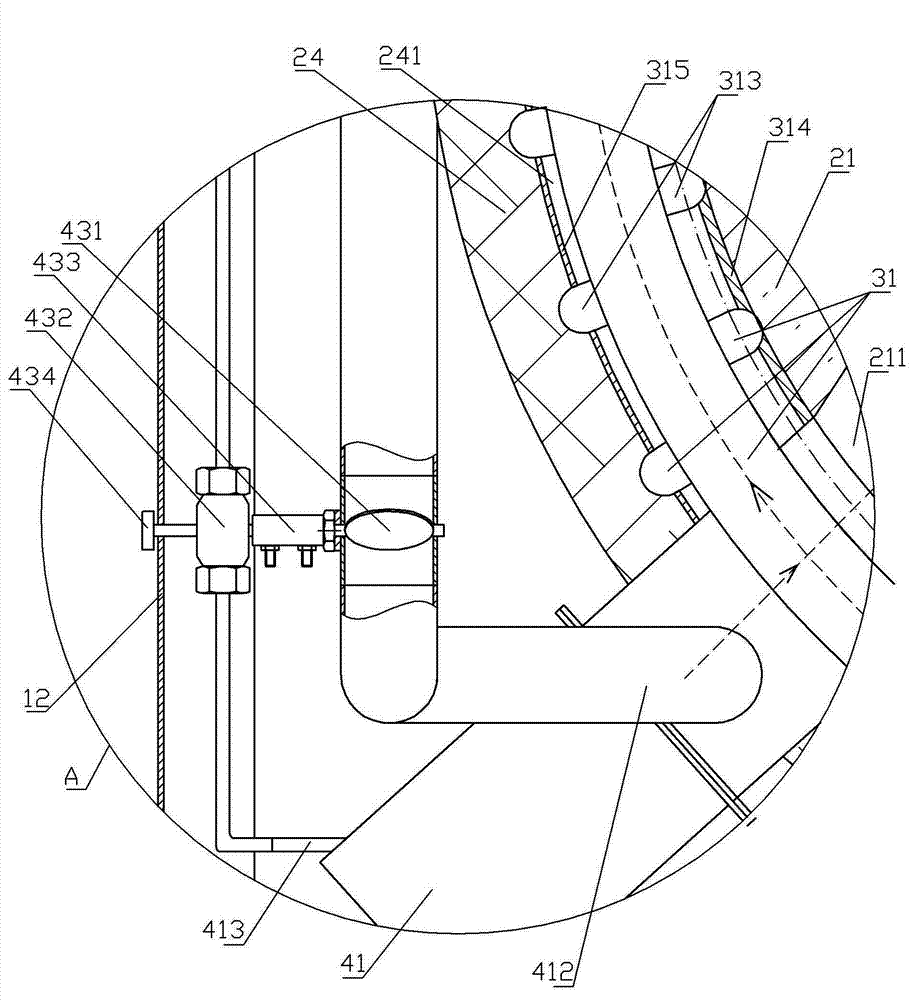

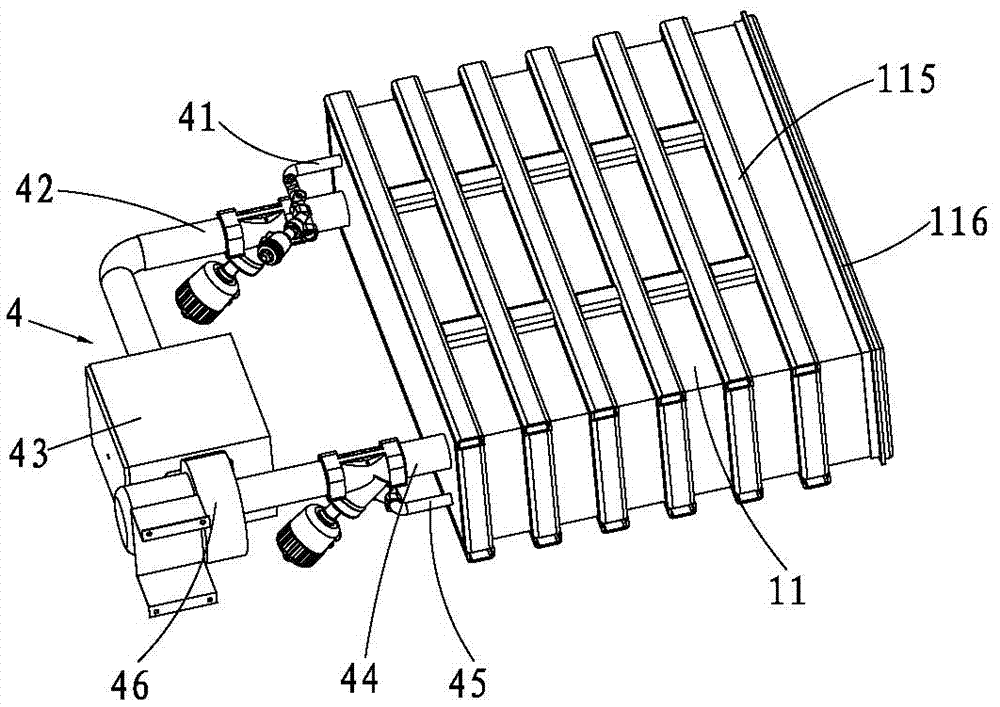

Multi-functional high-temperature efficient energy-saving steam oven

InactiveCN102927594AVersatileSave energyDomestic stoves or rangesSteam generation plantsEngineeringMultiple function

The invention discloses a multi-functional high-temperature efficient energy-saving steam oven which comprises an oven body, a steam generator (31) and a burner (41). The oven body comprises an oven core wall (21), an oven core spinning nest (23) and a heat preservation wall (24). A burning included channel (234) is formed between inner sides of the oven core spinning nest (23) and the heat preservation wall (24). The heat preservation wall (24) is arranged outside the oven core wall (21), an annular smoke waste heat absorbing cavity (241) is formed, and the steam generator (31) is arranged in the smoke waste heat absorbing cavity (241). The burner (41) is arranged on the heat preservation wall (24) and the steam generator (31). The multi-functional high-temperature efficient energy-saving steam oven can achieve purposes of frying and steaming simultaneously, is high in temperature inside the oven and heat energy use rate, sufficient in burning and energy-saving, and reduces environment pollution.

Owner:广东宏丁节能科技发展有限公司

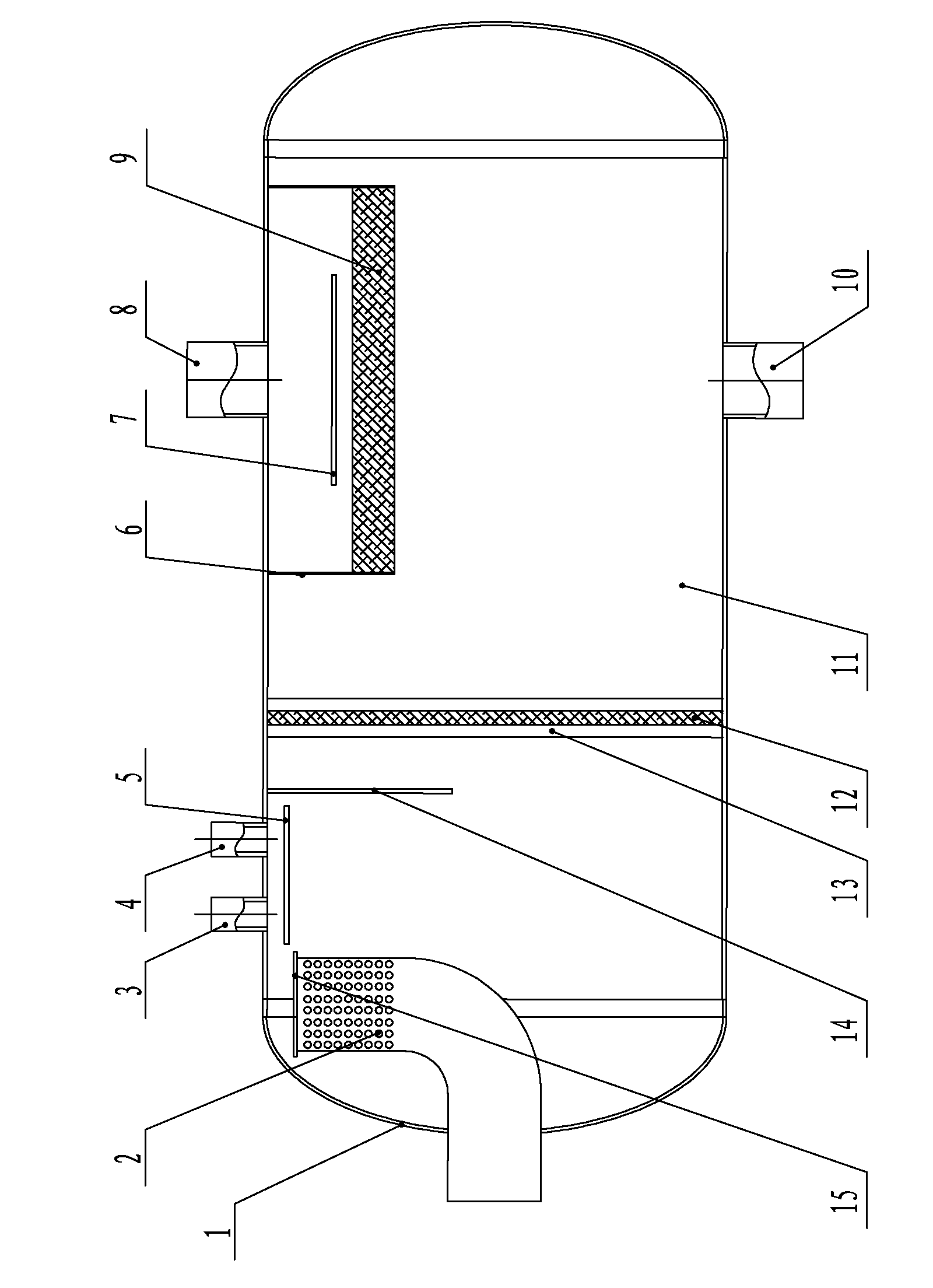

Horizontal flash tank for centrifugal unit

ActiveCN103256761ARun smoothlyImprove energy efficiency ratioNoise suppressionFluid circulation arrangementRefrigerantEngineering

The invention provides a horizontal flash tank for a centrifugal unit. The horizontal flash tank comprises a head, a shell body, a liquid inlet pipe, a liquid outlet, a liquid spraying liquid return opening and an oil cooling liquid return opening. The liquid inlet pipe and the head are welded deep in the inside of the flash tank, an end opening of the liquid inlet pipe is upward, the end portion of the liquid inlet pipe is drilled, and the end opening of the liquid inlet pipe is welded through a plug plate. The liquid spraying liquid return opening and the oil cooling liquid return opening are welded to the shell body, and an opening portion is provided with an impact-resistant baffle. A baffle, a certain distance from the impact-resistant baffle, is welded close to the right side of the impact-resistant baffle. The right side of the baffle is provided with a fixing gird plate and a first-level filtering screen which are welded to the shell body. An air absorbing baffle is arranged under an air outlet and welded to the shell body. A second-level filtering demisting screen assembly is arranged under the air absorbing baffle, two sides of the second-level filtering demisting screen assembly are provided with end plates, and the end plates and the second-level filtering demisting screen assembly are welded to the shell body. The horizontal flash tank can effectively lower noise and severe fluctuation of a liquid face generated after high-speed liquid refrigerants enters the flash tank, and eliminate the phenomenon that liquid exists in gas.

Owner:SHANDONG GRAD GROUP

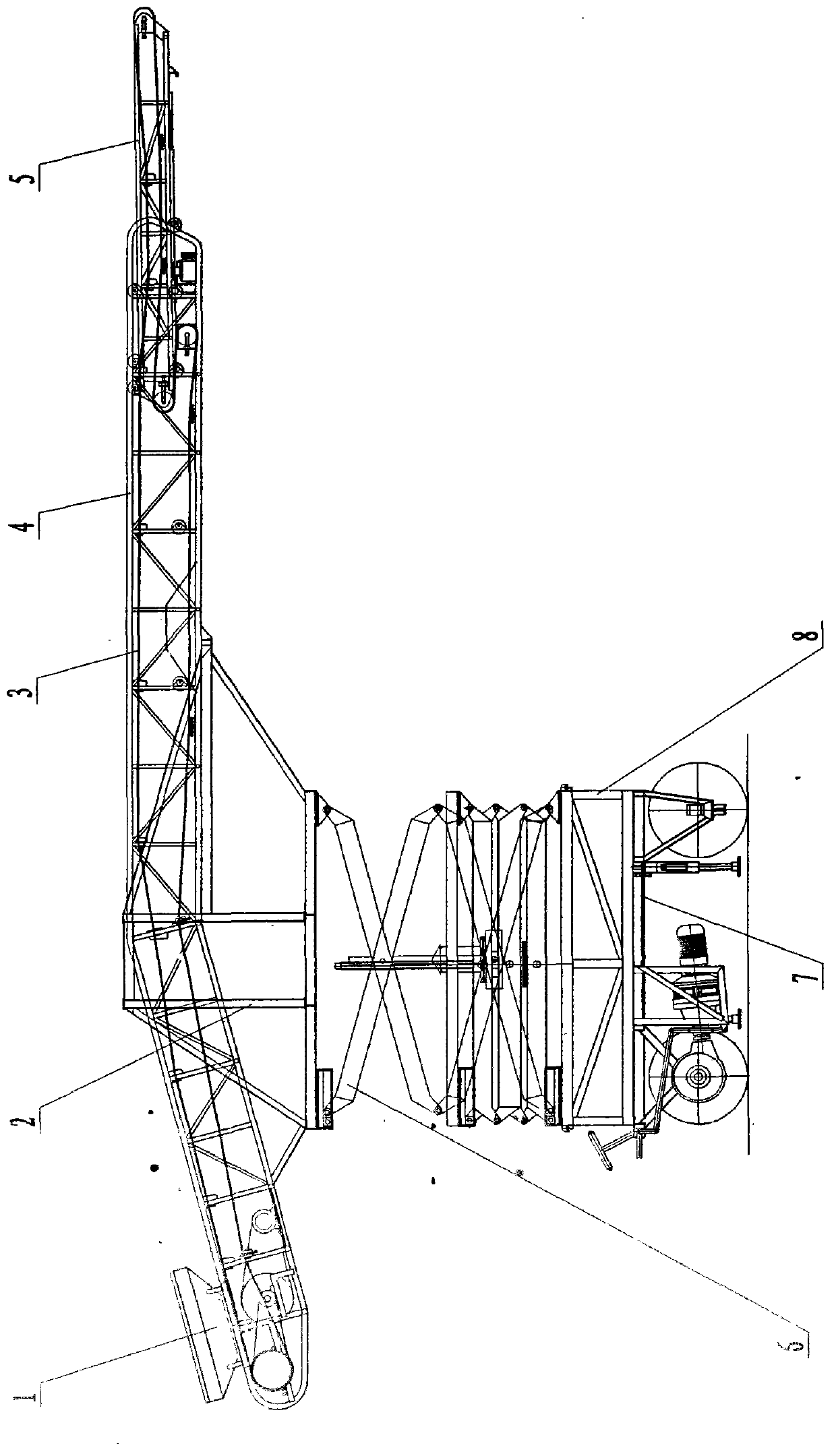

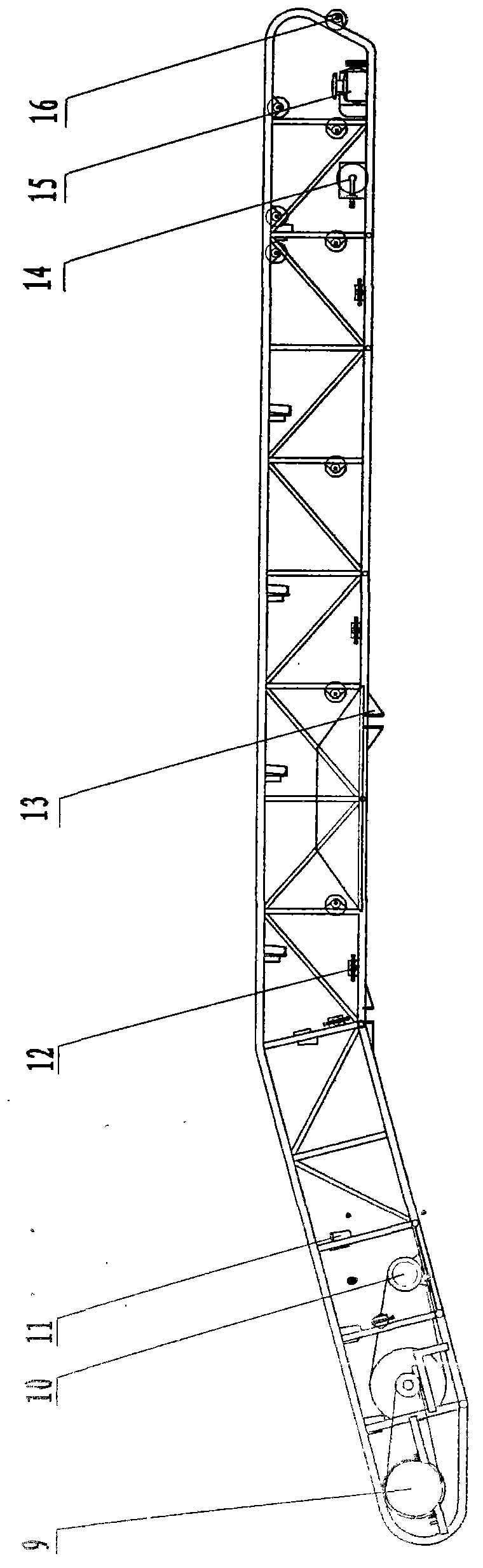

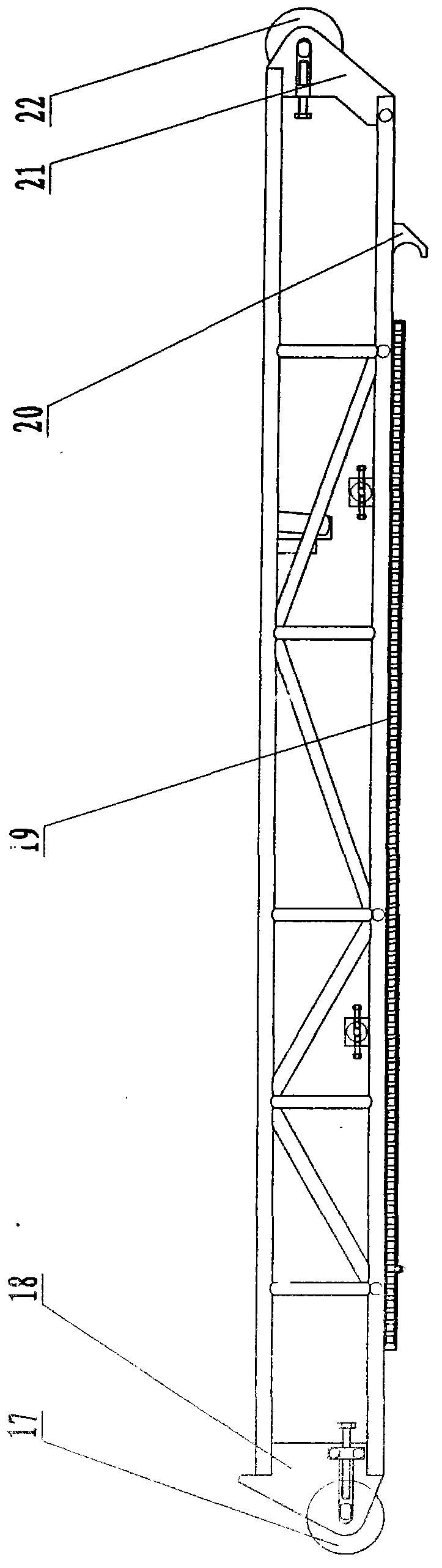

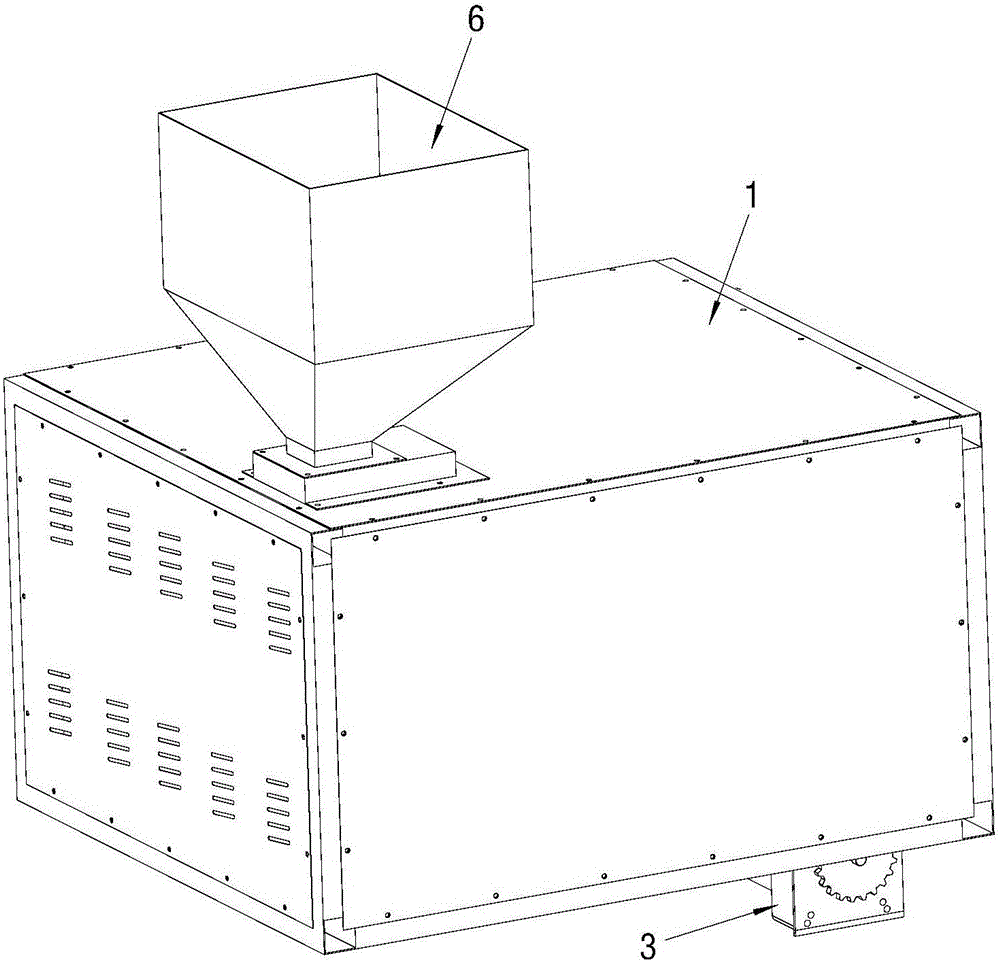

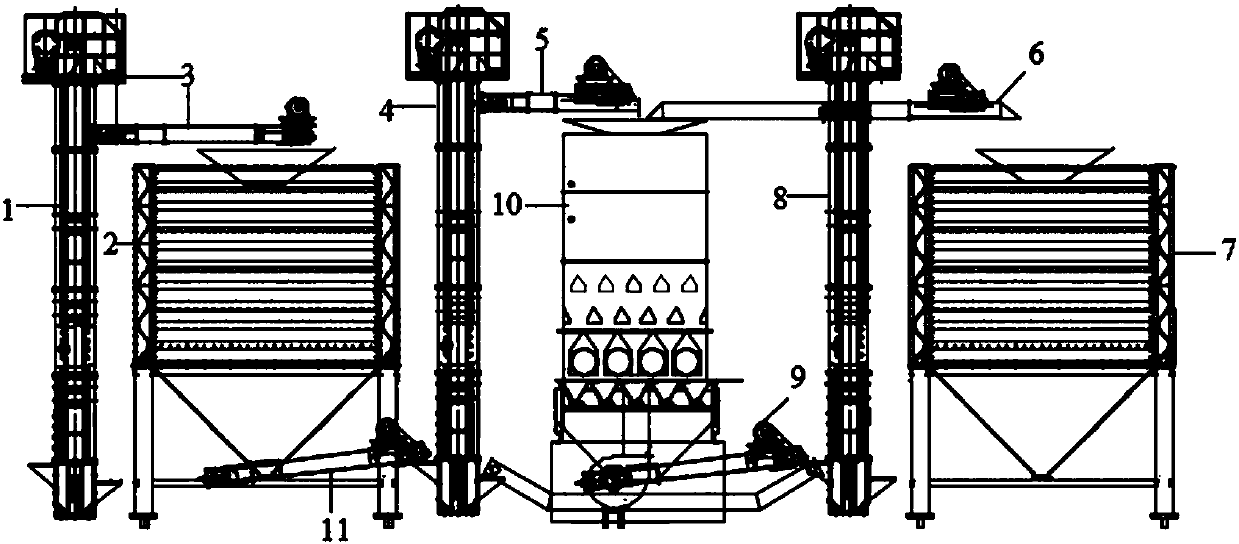

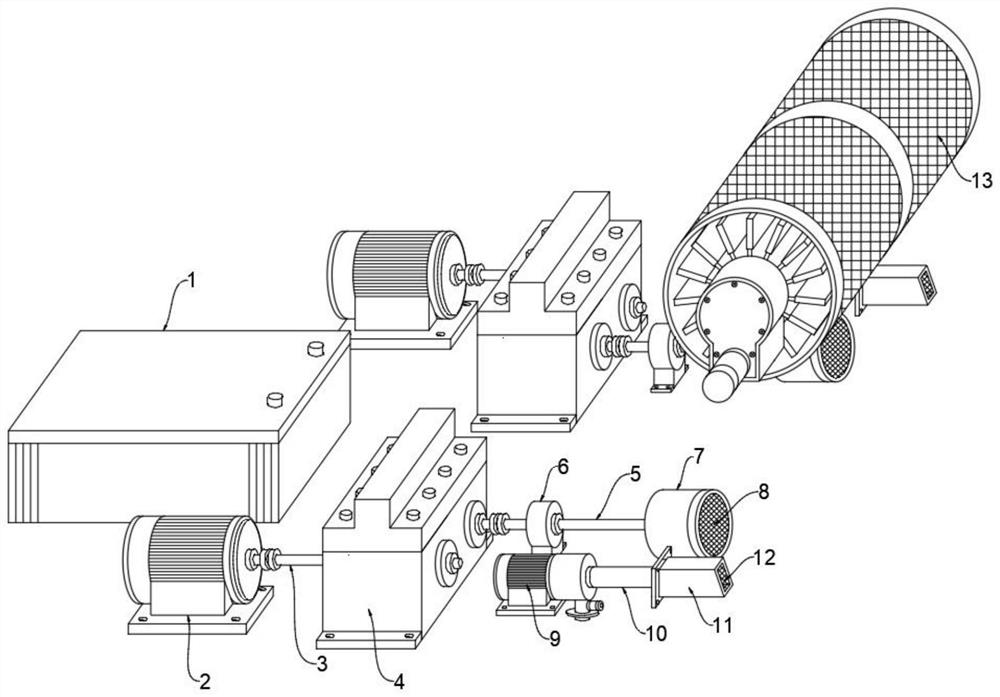

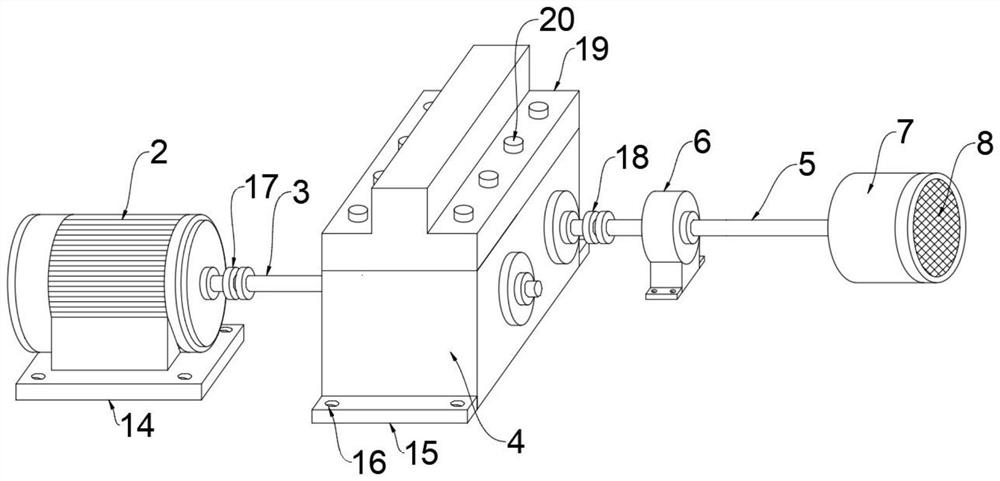

Movable and retractable type elevated grain binning machine

InactiveCN103863836AAdjustable conveying distanceExtend the entry distanceLoading/unloadingAutomatic controlElectric machinery

The invention discloses a movable and retractable type elevated grain binning machine, which is characterized in that an automobile chassis is adopted; an electric transmission mode is provided; the flexible variability of use conditions is improved; a lifting mechanism adopts a fork lever mechanism and an electric rectangular screw lifting mechanism, so that equipment is flexibly controlled to lift; as a retractable type framework structure is adopted for warehousing, the conveying distance of conveying equipment entering a grain bin can be adjusted; a main conveying rack is internally provided with a retractable sub-rack; after a conveying base rack is inserted into a window of the grain bin, the grain warehousing distance can be prolonged by stretching out the sub-rack; a lifting rack adopts a simple-structure fork lever combination and a rectangular screw combination with chain driving and automatic locking; the effect of automatic control on lifting is realized through motor control. According to the movable and retractable type elevated grain binning machine, as the automatic chassis is simultaneously adopted, and a driving mode of a motor and a cycloidal pinwheel speed reducer is also provided, the performances of free movement for workplace change, free retraction, simple operation and the like are realized; the effects of high efficiency and energy conservation are realized as well.

Owner:BEIJING ZHONGTIAN JINGU GRAIN OIL ENG TECH

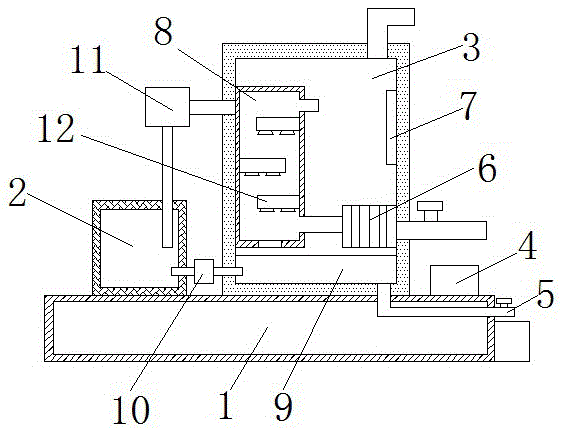

Efficient energy-saving environment-friendly dust treatment device

InactiveCN105664641ASimple structureSave waterCombination devicesDispersed particle filtrationEfficient energy useEngineering

The invention discloses an efficient energy-saving environment-friendly dust treatment device which comprises a base.The upper surface of the base is sequentially provided with a water tank, a dust removal box and a controller from left to right.The right end of the base is provided with a garbage collection box.The bottom of the dust removal box is provided with a blow-off pipe.The end, away from the dust removal box, of the blow-off pipe sequentially penetrates through the upper surface and the right side face of the base and extends out of the base.A primary dust removal device is arranged on the lower middle portion of the inner wall of the right side of the dust removal box.An ultraviolet disinfection lamp is arranged on the upper middle portion of the inner wall of the right side of the dust removal box.An air inlet pipe is arranged on the right side face of the dust removal box in a penetrating mode.The air inlet pipe extends into the dust removal box and is connected with the primary dust removal box.According to the efficient energy-saving environment-friendly dust treatment device, the primary dust removal device and a secondary dust removal device in the dust removal box achieve the effect of thoroughly filtering and removing dust, water treated through the secondary dust removal device falls into a sedimentation basin, a water pump recycles clean water into the water tank again, and water resources are saved.

Owner:林丽芳

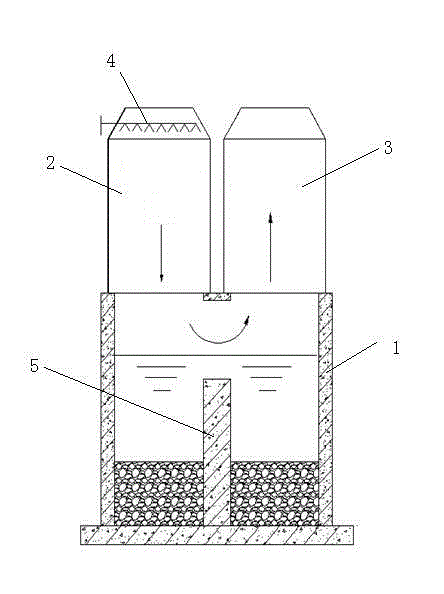

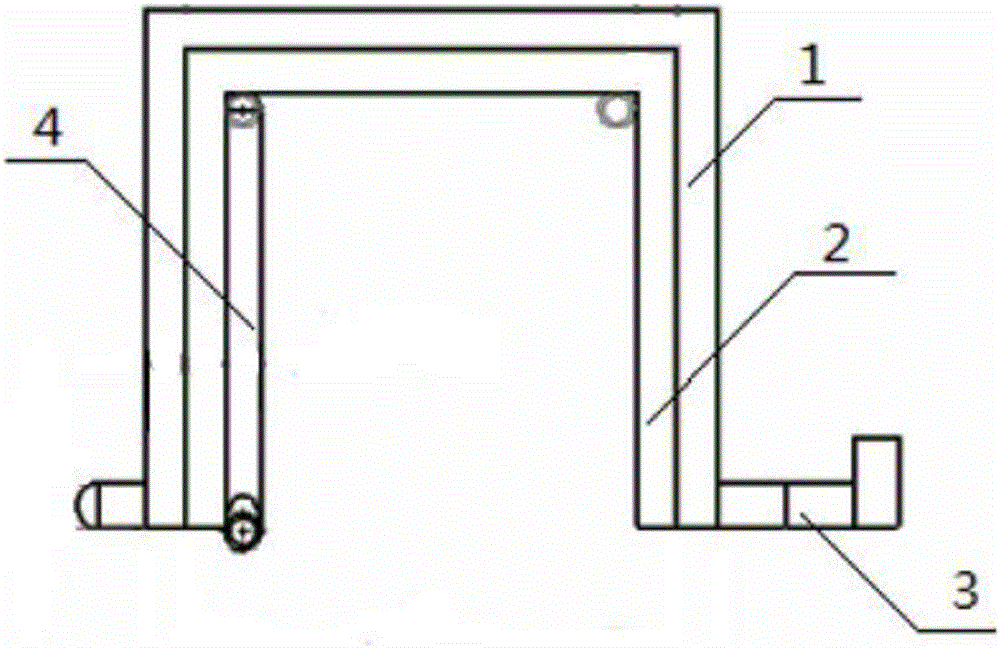

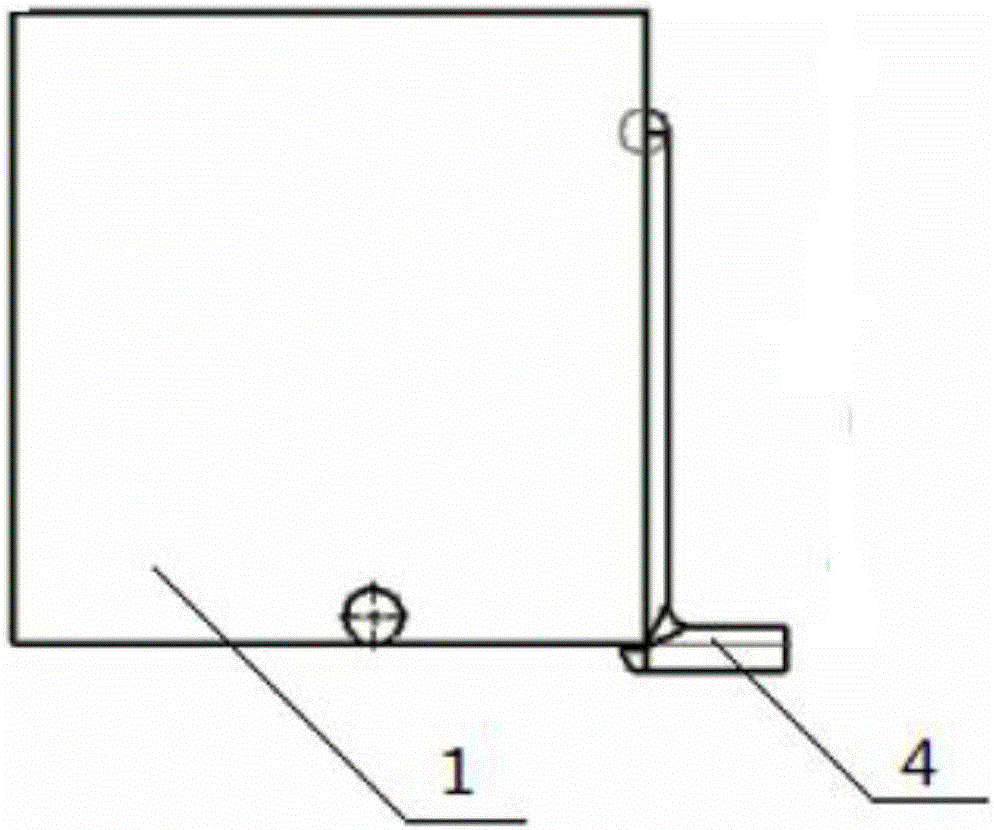

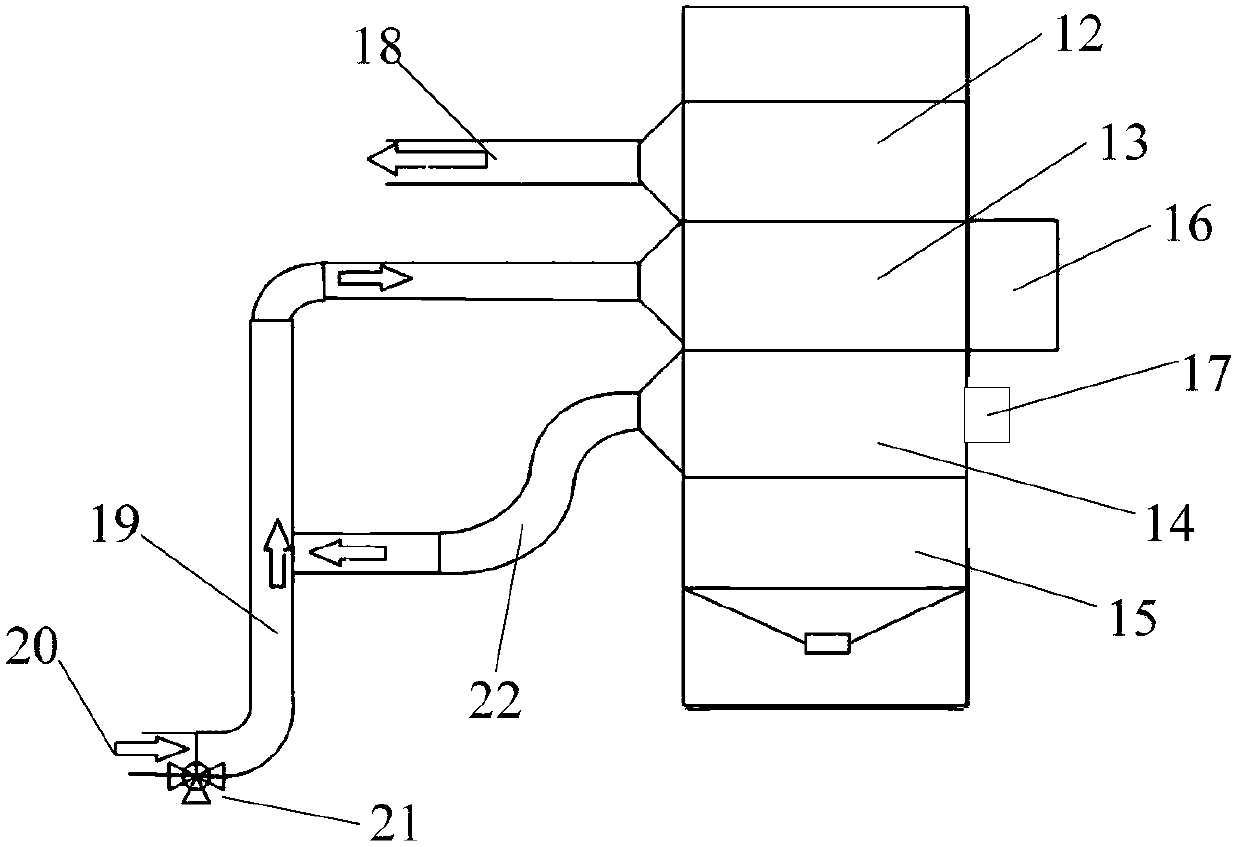

Wet-type desulfurizing deduster downstream spraying structure

InactiveCN102743942AReduce motor powerSmall running resistanceCombination devicesUsing liquid separation agentEngineeringMotor power

The invention discloses a wet-type desulfurizing deduster downstream spraying structure, which is characterized by comprising a base cylinder (1), which is provided with a desulfurizer cylinder (2) and a dehydrator cylinder (3). The upper port diameters of the desulfurizer cylinder (2) and the dehydrator cylinder (3) are both smaller than the lower port diameters. A spraying pipe (4) is disposed at the upper port of the desulfurizer cylinder (2). While meeting the desulfurization effect requirement, the spraying structure disclosed in the invention can reduce the equipment running resistance by 400-500Pa and greatly reduce the motor power of a fan, thus really reaching the effects of high efficiency and energy saving. The running mode is safe and reliable, the equipment resistance is small. Simultaneously, a lot of energy can be saved, and the running cost is low.

Owner:无锡翱翔环保机械有限公司

Distribution method of heat consumption of fuel gas and steam combined cycle combined heat and power generation unit

InactiveCN108644858AImprove power generation efficiencyBest ratioLighting and heating apparatusSpace heating and ventilation detailsDistribution methodCogeneration

Owner:南京瑞松信息科技有限公司

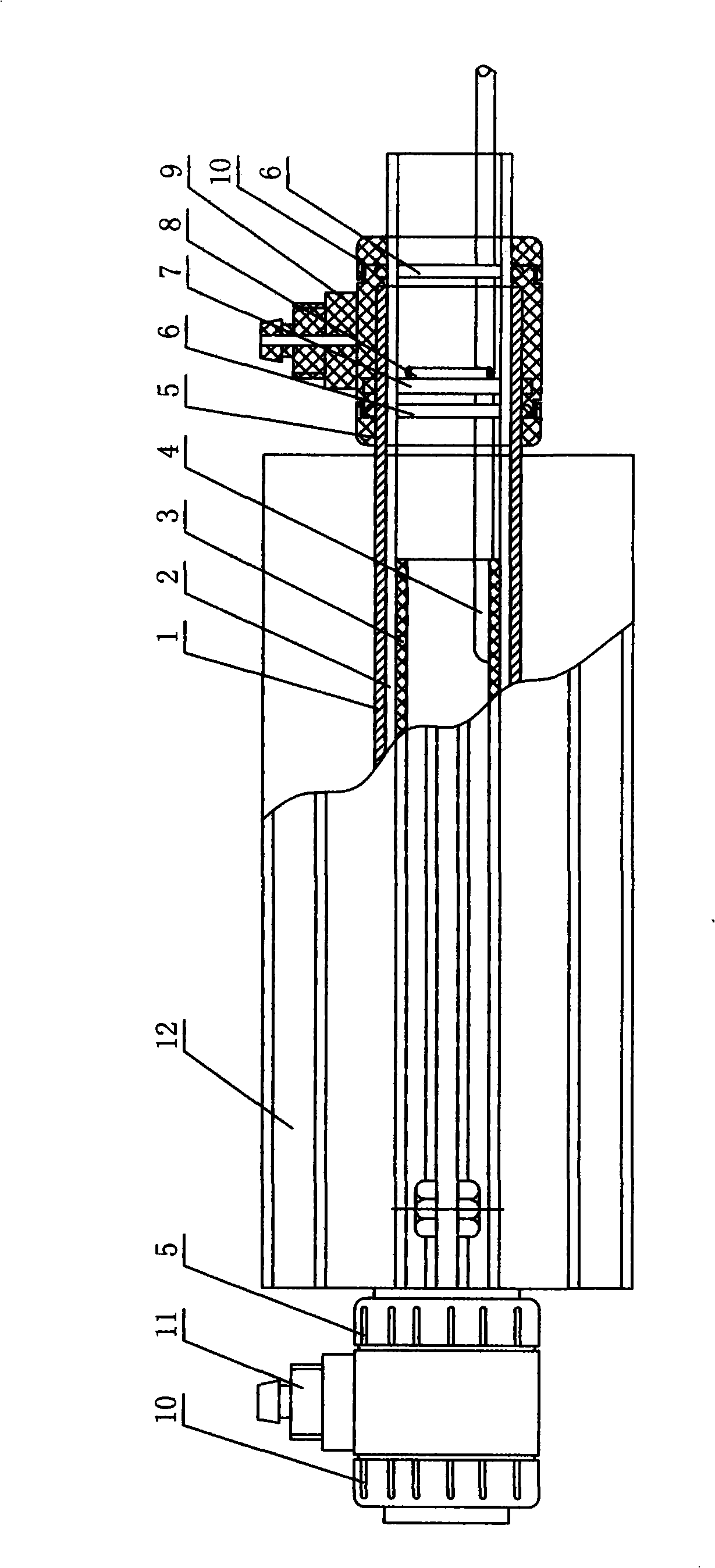

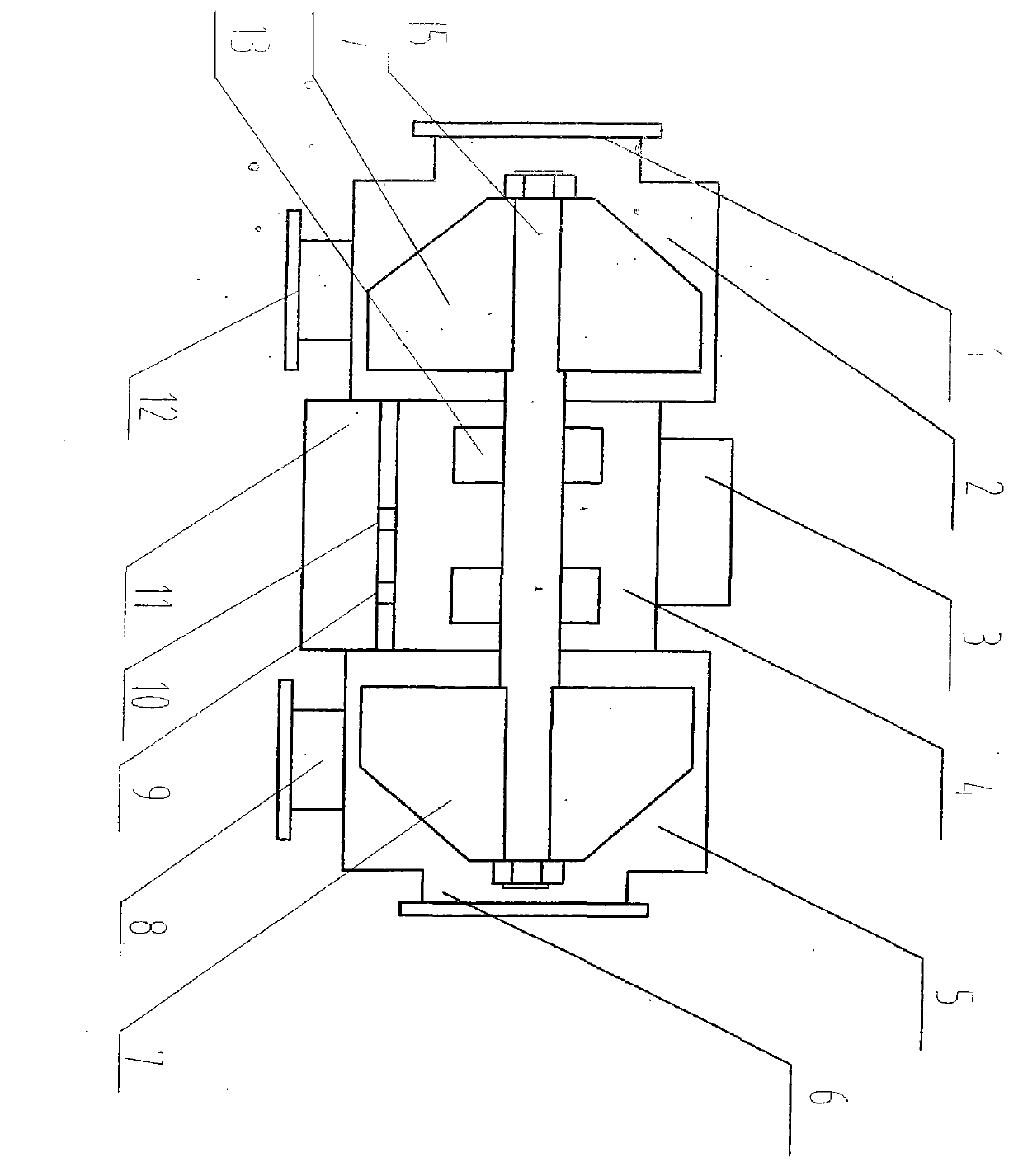

High-frequency high-voltage energy-saving ozone generator

InactiveCN101559928AIncrease temperatureExtended service lifeOzone preparationEngineeringHigh pressure

The invention relates to a high-frequency high-voltage energy-saving ozone generator which utilizes ozone for sterilization, disinfection and deodorization and is suitable for an ozone machine. The high-frequency high-voltage energy-saving ozone generator comprises an outer metal electrode tube, a silica tube, an inner electrode, a high-voltage wire, an inner sealing cover, sealing rings, positioning rings, positioning clamps, a generator air inlet nozzle, an outer sealing cover, a generator air outlet nozzle and an aluminum alloy radiator, wherein the outer metal electrode tube is sleeved on the outer layer of the silica tube, and the inner electrode is arranged on the inner wall of the silica tube; a layer of graphite is coated on the inner wall of the silica tube, and the inner electrode is embedded in the graphite and connected with the high-voltage wire; the generator air inlet nozzle and the generator air outlet nozzle are respectively arranged at two top ends of the outer metal electrode tube, and the sealing rings, the positioning rings and the positioning clamps are respectively arranged in the two generator air nozzles; the inner sealing cover and the outer sealing cover are in threaded connection with the generator air inlet nozzle, and a semi-circular arc of the aluminum alloy radiator is vertically clamped on the outer metal electrode tube. The ozone generator achieves the effects of high efficiency and energy saving by the structural innovative method and solves the technical problem that wind cooling is inferior to water cooling.

Owner:盐城市亨泰环保设备制造有限公司

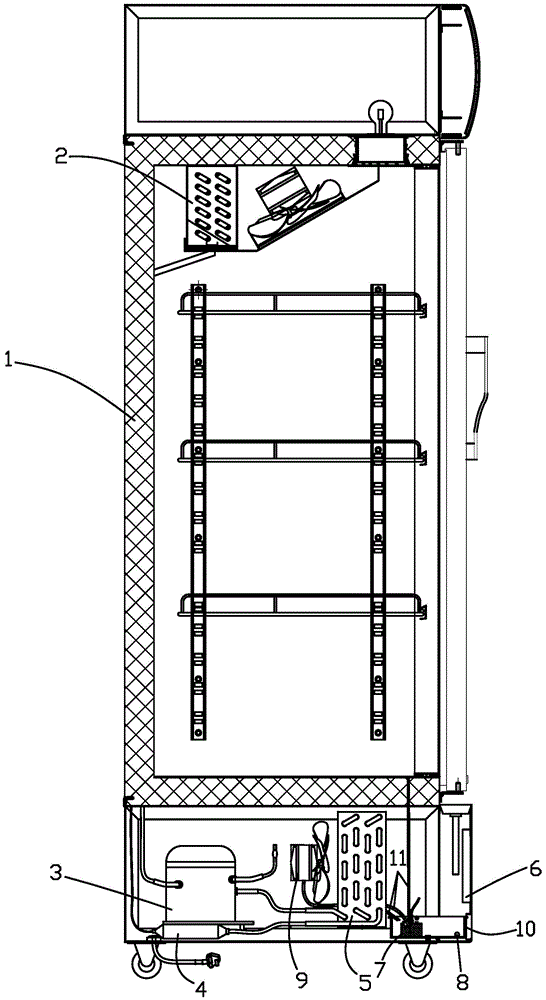

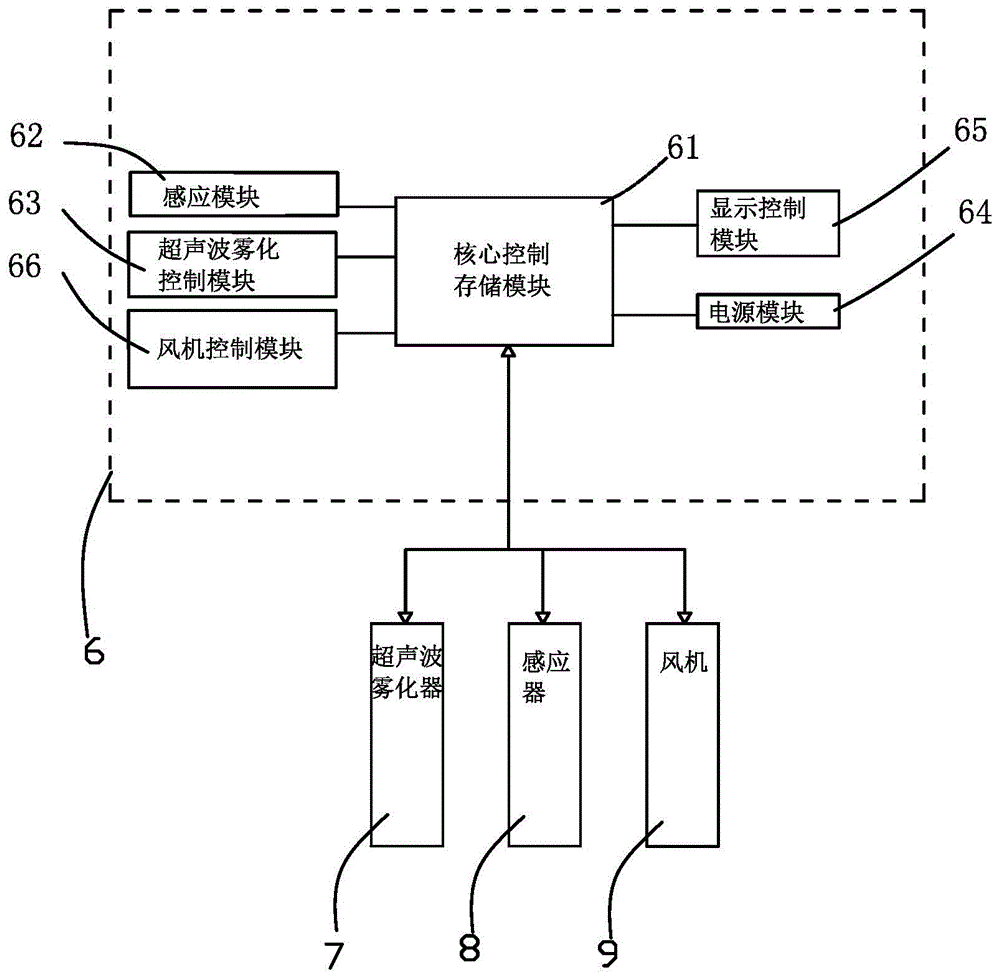

Refrigerator defrosting water heat dissipation system

InactiveCN105020966AExtended service lifeIntelligent control of cooling effectLighting and heating apparatusDefrostingUltrasonic nebulizersInductor

The invention provides a refrigerator defrosting water heat dissipation system which comprises a refrigerator body. An evaporator, a compressor, a filter and a condenser are arranged in the refrigerator body. The system is characterized in that an intelligent controller, an ultrasonic nebulizer, an inductor and a water collection cup are further arranged in the refrigerator body, the draught fan and the water collection cup are arranged on one side of the condenser, drainage pipes are arranged in the condenser and the refrigerator respectively to be connected with the water collection cup, the ultrasonic nebulizer and the inductor are arranged in the water collection cup, and the intelligent controller is connected with the ultrasonic nebulizer, the inductor and the draught fan. Defrosting water and condensed water in the refrigerator body are guided into the water collection cup through the drainage pipes, the intelligent controller acquires induction of the inductor to the water amount and then starts or stops the ultrasonic nebulizer and adjusts and controls the speed of the draught fan. The refrigerator defrosting water heat dissipation system is high in controllability and practical and is an intelligent efficient heat dissipation and energy conservation system, manual water pouring operation can be omitted, and the system is particularly suitable for a commercial exhibition refrigerator.

Owner:广州市穗凌电器有限公司

Portable refrigeration transport channel

InactiveCN106285092AReduce heatAchieve high efficiency and energy saving effectDomestic cooling apparatusLighting and heating apparatusRefrigerator carHeat flow

The invention discloses a convenient and telescopic refrigeration transport channel. The invention includes a channel airflow layer, a folded insulation layer, a moving cold source and a telescopic air duct, wherein the folded insulation layer is provided at the inner side of the channel airflow layer, the moving cold source is communicated with the telescopic air duct, and the telescopic air duct, consistent with the channel in length, is attached to the inner side of the folded insulation layer. The transport channel of the invention is provided between a refrigerator car and a cold storage. Due to the folding characteristics, the portable refrigeration transport channel can protect frozen goods, and also reduces the heat flowing into the cold storage and the refrigerator car, thereby achieving the effects of high efficiency and energy saving, and providing a transport environment suitable for freezing chilled foods and retaining freshness for the channel between the cold storage and the moving refrigeration.

Owner:TIANJIN UNIV OF COMMERCE

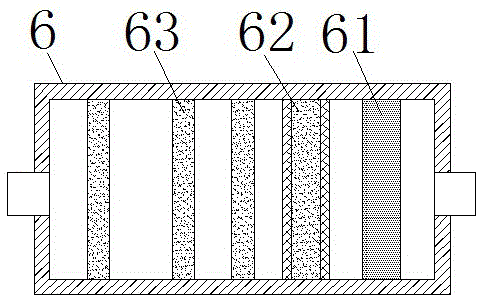

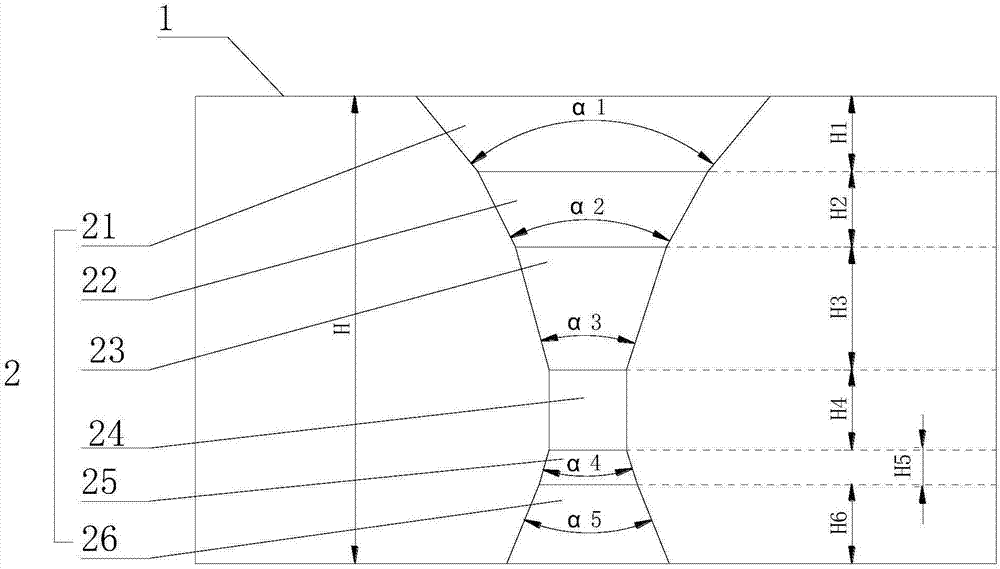

Steel cord wire-drawing die

The invention provides a steel cord wire-drawing die. The steel cord wire-drawing die comprises a die body; a wire drawing hole is formed in the die body; the conical angle of an inlet zone is alpha 1; the conical angle of a lubrication zone is alpha 2; the conical angle of a sizing zone is alpha 3; the conical angle of a decompression zone is alpha 4; the conical angle of an outlet zone is alpha 5; and alpha 1 is greater than alpha 2; alpha 2 is greater than alpha 5; alpha 5 is greater than alpha 3; alpha 3 is equal to alpha 4; the height of the die body is H; the height of the inlet zone is H1; the height of the lubrication zone is H2; the height of a working zone is H3; the height of the sizing zone is H4; the height of the decompression zone is H5; the height of the outlet zone is H6; H3 is greater than H4; H4 is greater than H6; H6 is greater than H2; H2 is equal to H1; and H1 is greater than H5. According to the steel cord wire-drawing die, during wire drawing, stability of a metal wire is increased; the metal wire can transit smoothly, so that the metal wire is not easily broken; thickness of the product is uniform; plastic deformation and elastic deformation of the metal wire are reduced; the conical angle of the working zone is equal to that of the decompression zone, so that reduction and uniform distribution of the friction force are favorably realized during a drawing process of the metal wire; abrasion of a die hole of the wire-drawing die is lowered; heat generated by friction of the metal wire and the die can be dissipated in time; and the service life of the die is prolonged.

Owner:杨飞

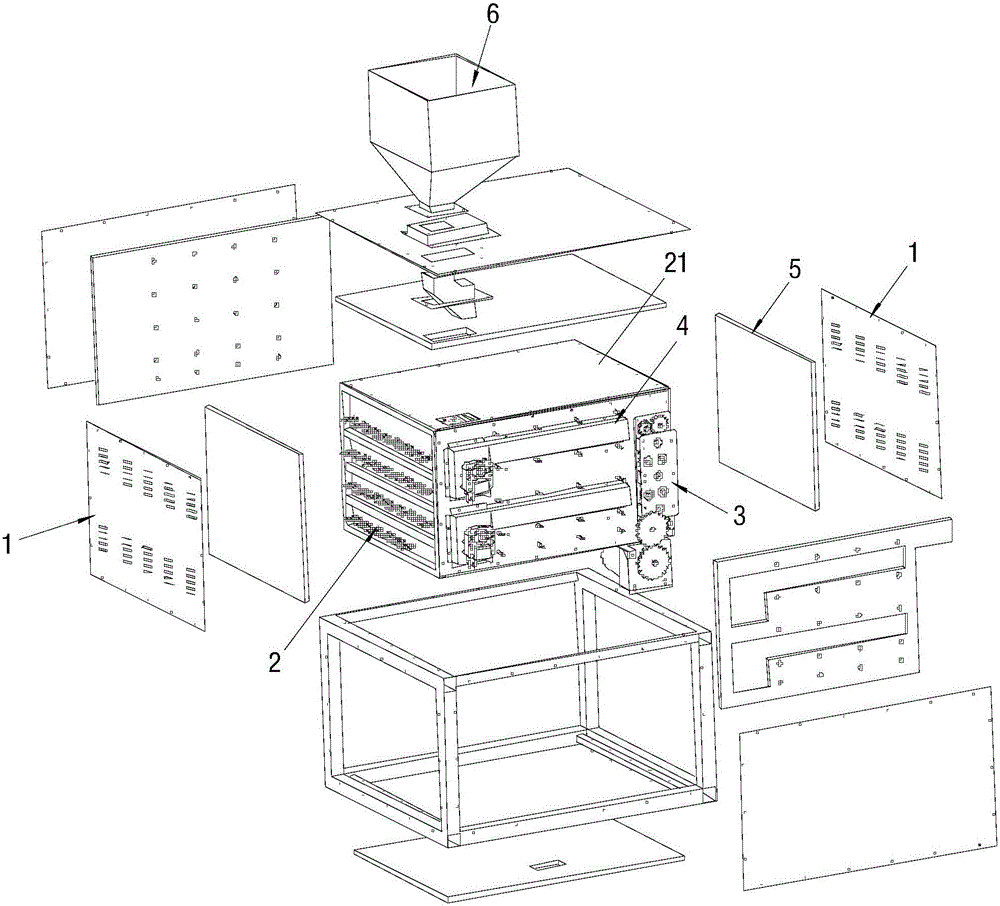

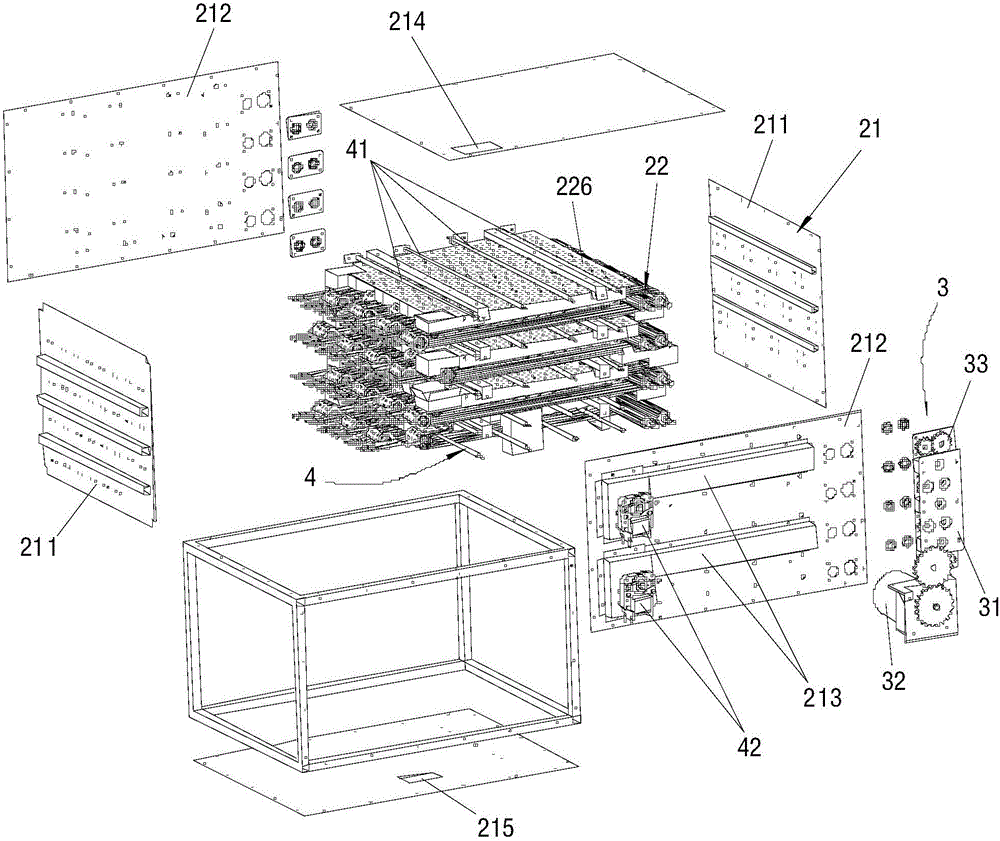

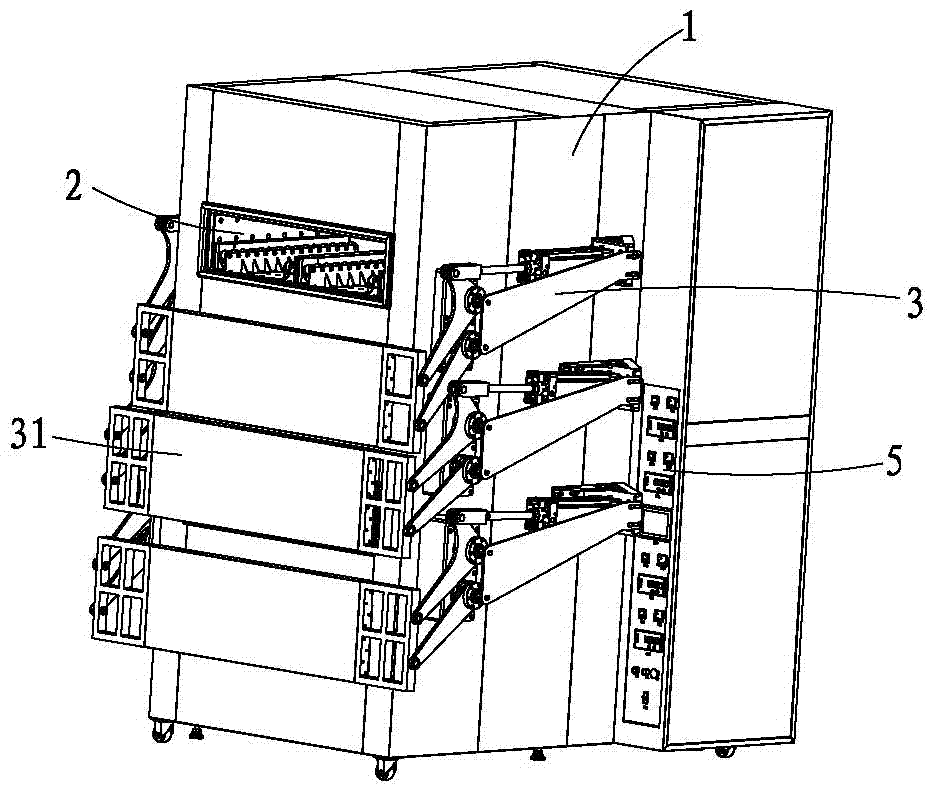

Baking device

ActiveCN106029856AReduce lossAchieve high efficiency and energy saving effectFatty-oils/fats productionFood treatmentCooking & bakingEngineering

Provided is a baking device, comprising a housing (1) and a transfer mechanism (2), a driving mechanism (3) and a baking mechanism (4) which are all arranged in the housing, wherein the baking mechanism penetrates the transfer mechanism; the transfer mechanism comprises an inner housing (2) and a plurality of transfer units (22) laminated in the inner housing at intervals and connected to the driving mechanism; the transfer paths of two adjacent transfer units are connected. The transfer unit comprises a guiding frame (225), a forward transfer element (221) and a reverse transfer element (222); the transfer directions of the forward transfer element and the reverse transfer element are opposite; and the forward transfer element and the reverse transfer element are staggered. According to the invention, the plurality of transfer units are laminated at intervals, and the transfer paths of two adjacent transfer units are connected, so that a enough long baking transfer path is realized under a certain occupation space, thereby increasing a space utilization rate, guaranteeing baking quality, and meanwhile reducing production costs.

Owner:东莞市乾道食品有限公司

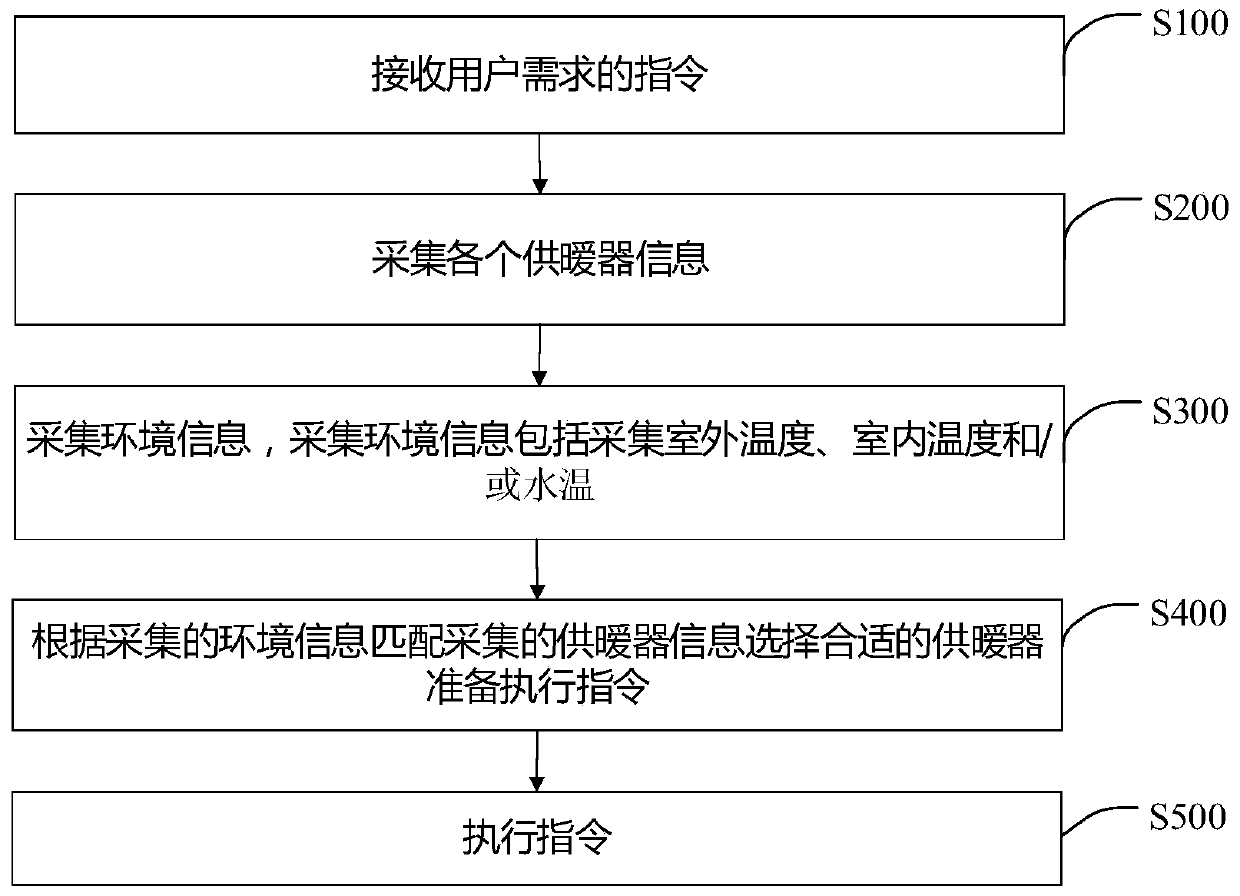

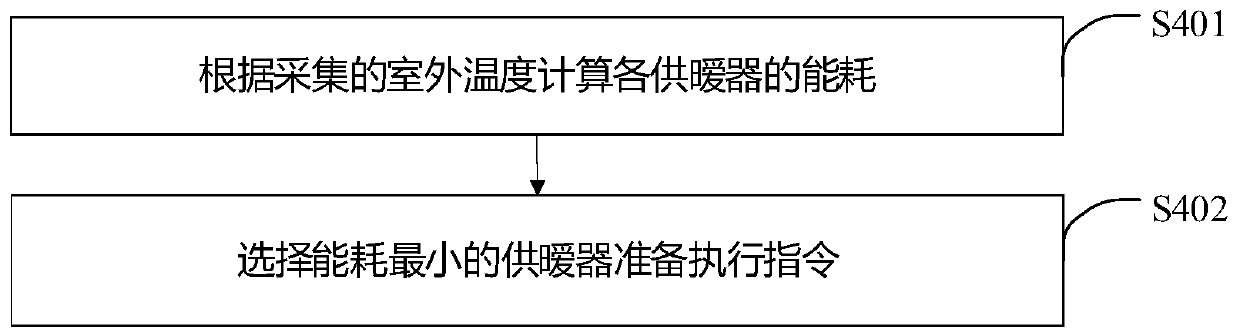

Energy-saving heating equipment and control method and system thereof

ActiveCN109915886AHigh degree of automationAvoid wasting energyLighting and heating apparatusSpace heating and ventilation detailsOutdoor temperatureEngineering

The invention is applicable to the technical field of energy-saving heating, and provides energy-saving heating equipment and a control method and system thereof. The method comprises the following steps of receiving instructions of demands of users; collecting the information of each heater; collecting the environmental information, specifically, the collection of the environmental information comprises the collection of outdoor temperature, indoor temperature and / or water temperature; according to the collected environmental information matching the collected information of the heaters, selecting the appropriate heater to prepare for executing instructions; and executing the instructions. By means of the energy-saving heating equipment and the control method and system thereof, the degree of automation is effectively improved, and energy is saved by collecting the environmental information and matching the most suitable heater according to the environmental information for heating.

Owner:SHENZHEN ALLIED CONTROL SYSTEM CO LTD

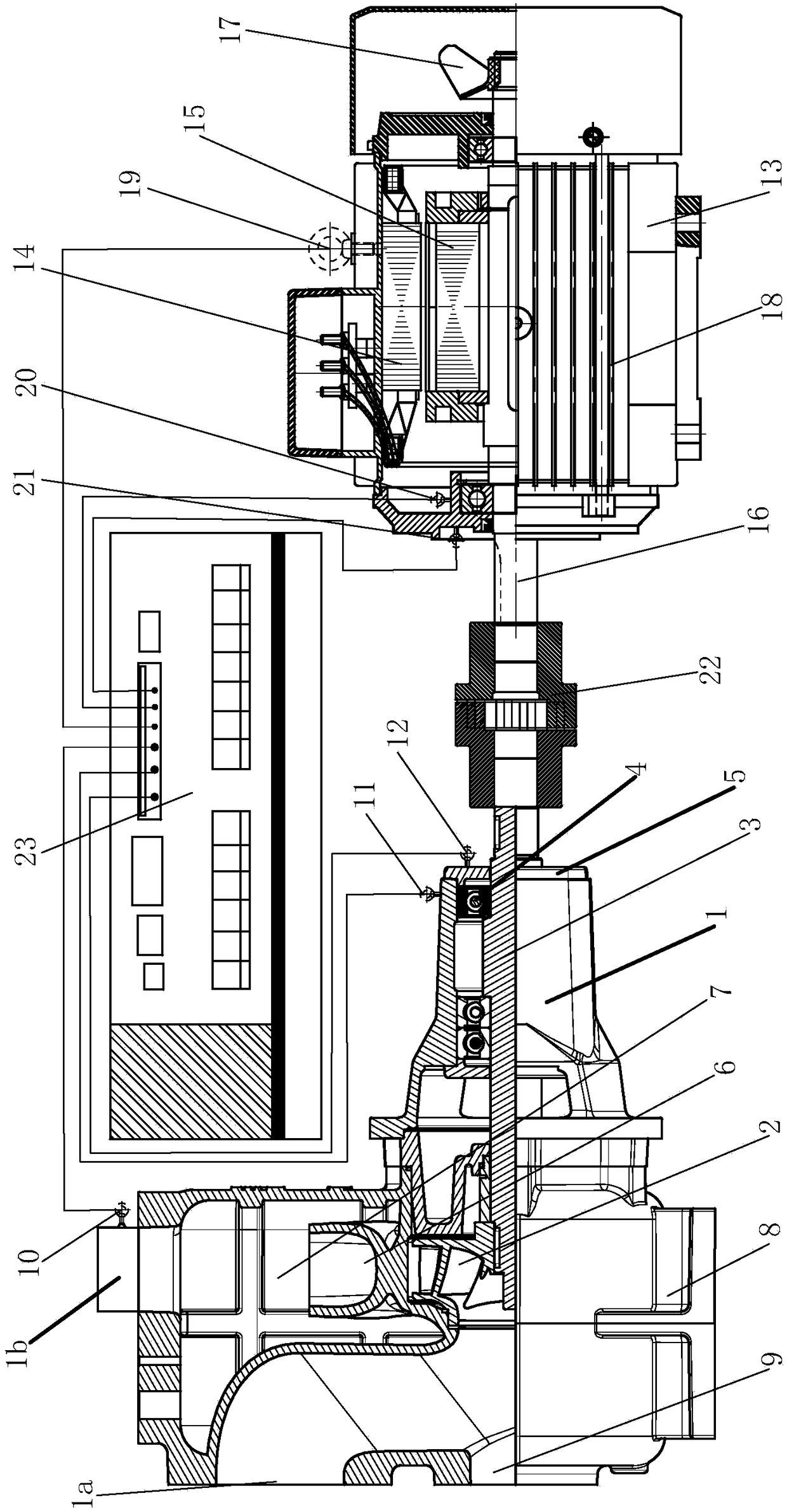

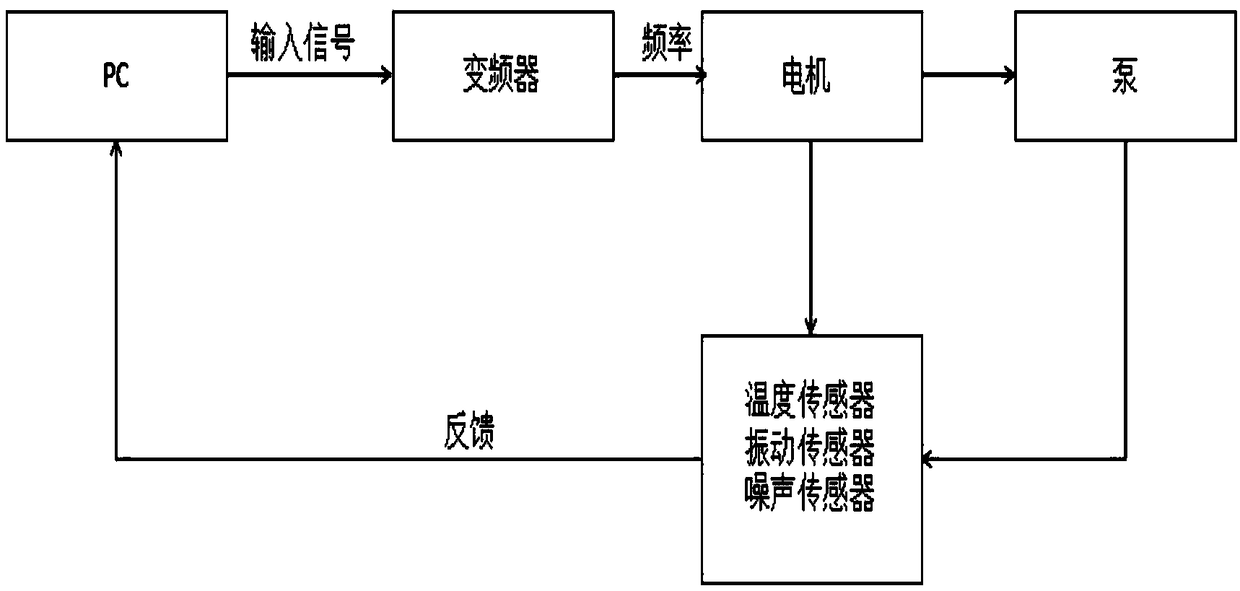

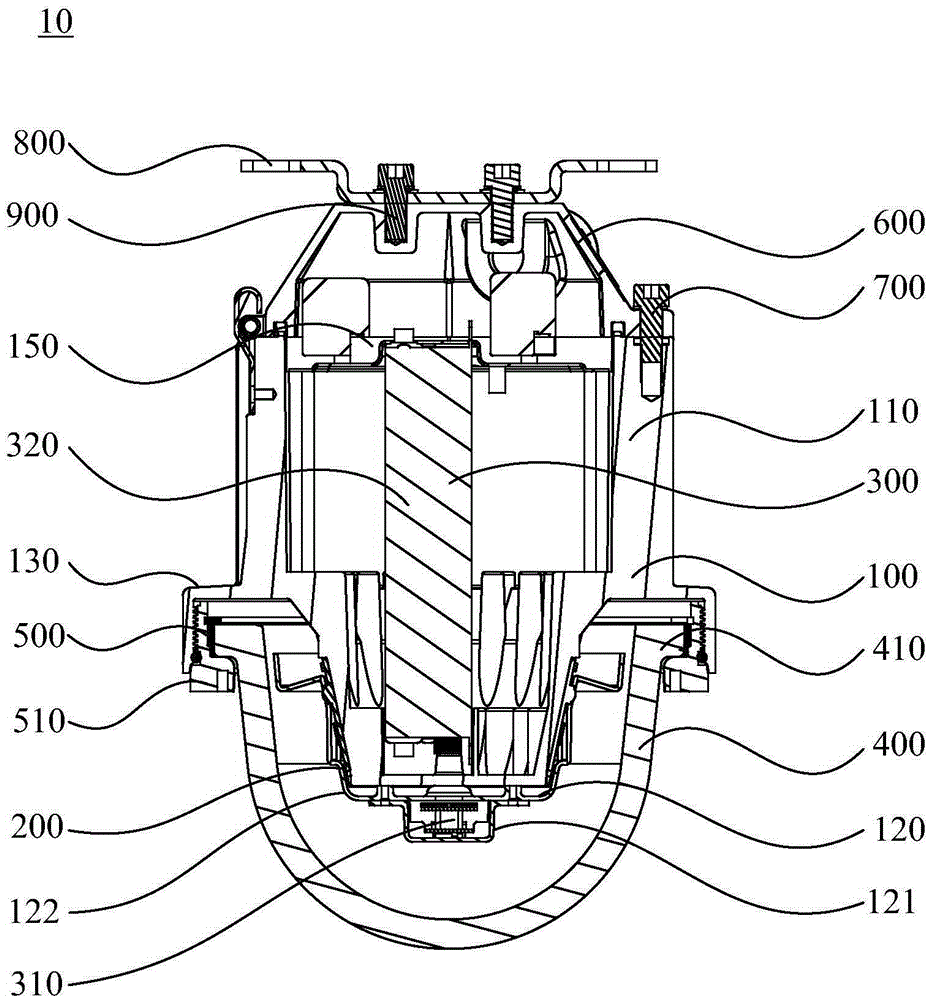

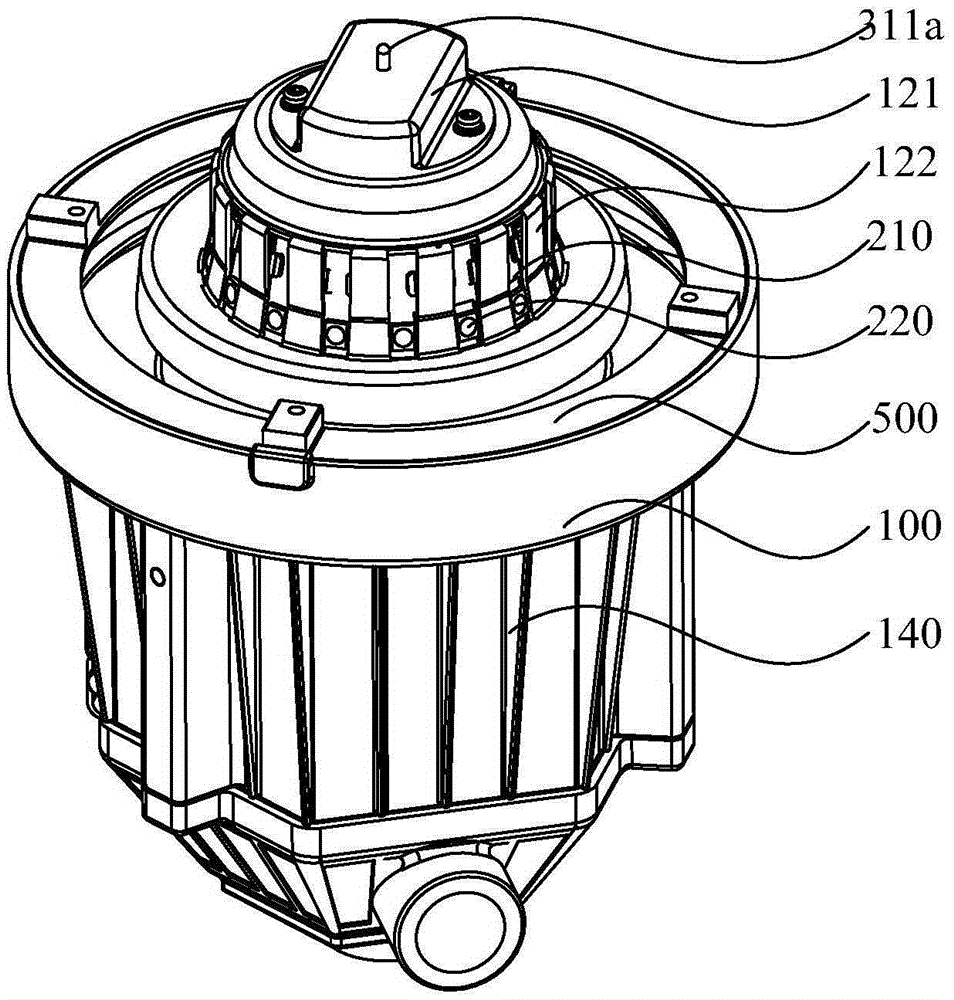

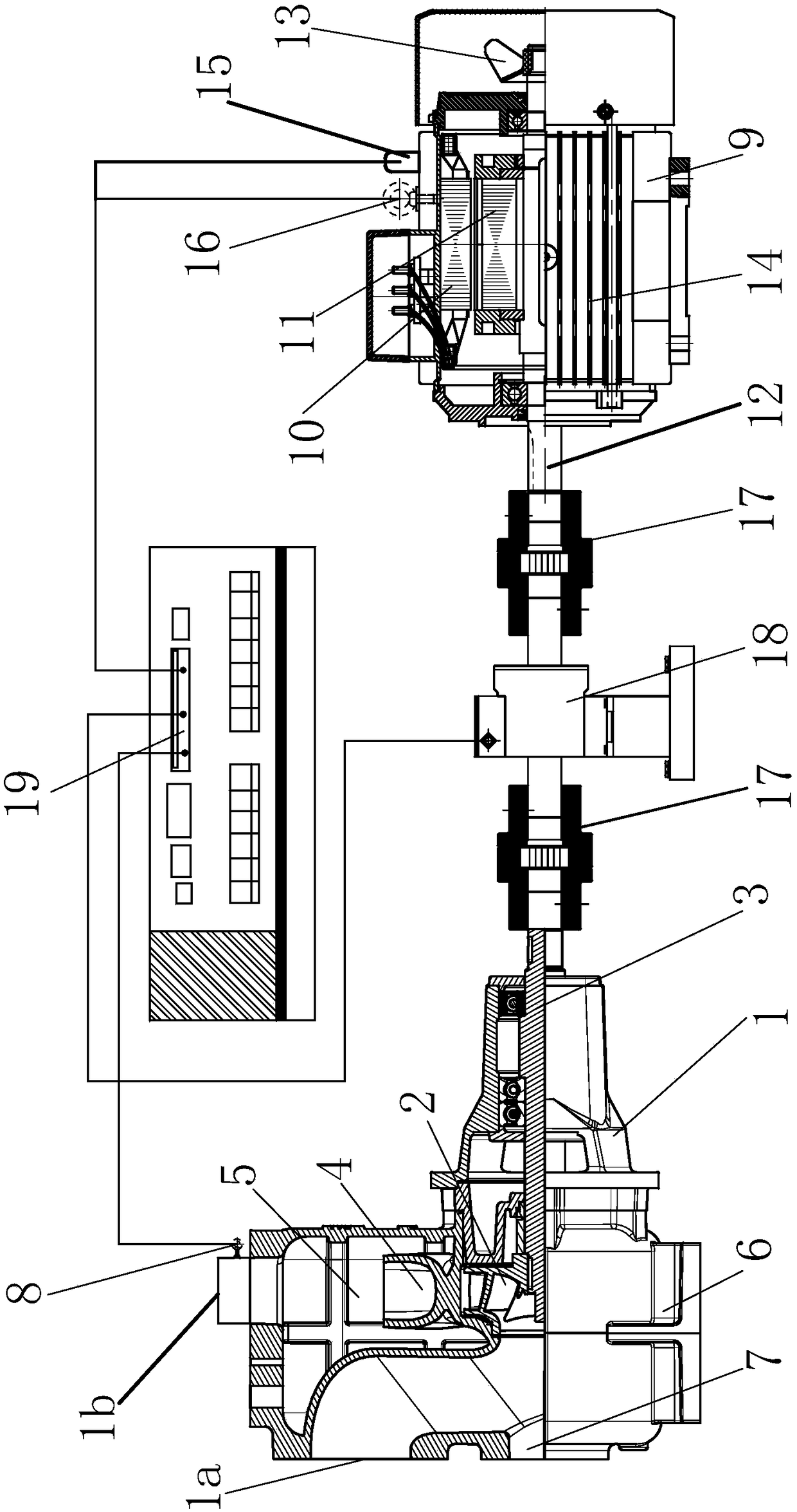

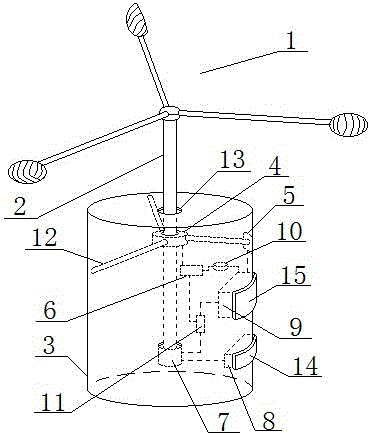

Centrifugal pump and permanent magnet motor safe operation control device and regulation and control method thereof

PendingCN108488075AGuaranteed uptimePlay a preventive rolePriming pumpPump controlFrequency changerPermanent magnet synchronous motor

The invention provides a centrifugal pump and permanent magnet motor safe operation control device and a regulation and control method thereof. According to the centrifugal pump and permanent magnet motor safe operation control device, an impeller is arranged in a pump shell of a centrifugal pump, the transmission end of a pump body shaft of the impeller is sleeved with a pump bearing and a pump end cover, a water inlet and a water outlet are formed in the pump shell, and a noise sensor is arranged at the water outlet; a pump body temperature sensor and a pump body vibration sensor are arranged at the pump end cover, and the noise sensor, the pump body temperature sensor and the pump body vibration sensor are connected with a servo driver through electric wires; a stator and a rotor are arranged in a motor shell of a permanent magnet synchronous motor, the driving end of a motor shaft of the rotor is sleeved with a motor bearing and a motor end cover, a first temperature sensor is arranged on the outer wall of the motor shell, a second temperature sensor and a motor vibration sensor are arranged at the motor end cover, and the first temperature sensor, the second temperature sensorand the motor vibration sensor are connected with the servo driver through electric wires; and the motor shaft is fixedly connected with the pump body shaft through a coupler, and the servo driver isconnected with the permanent magnet synchronous motor through a frequency converter in an electrical control mode.

Owner:ZHEJIANG YONGFA ELECTROMECHANICS LTD

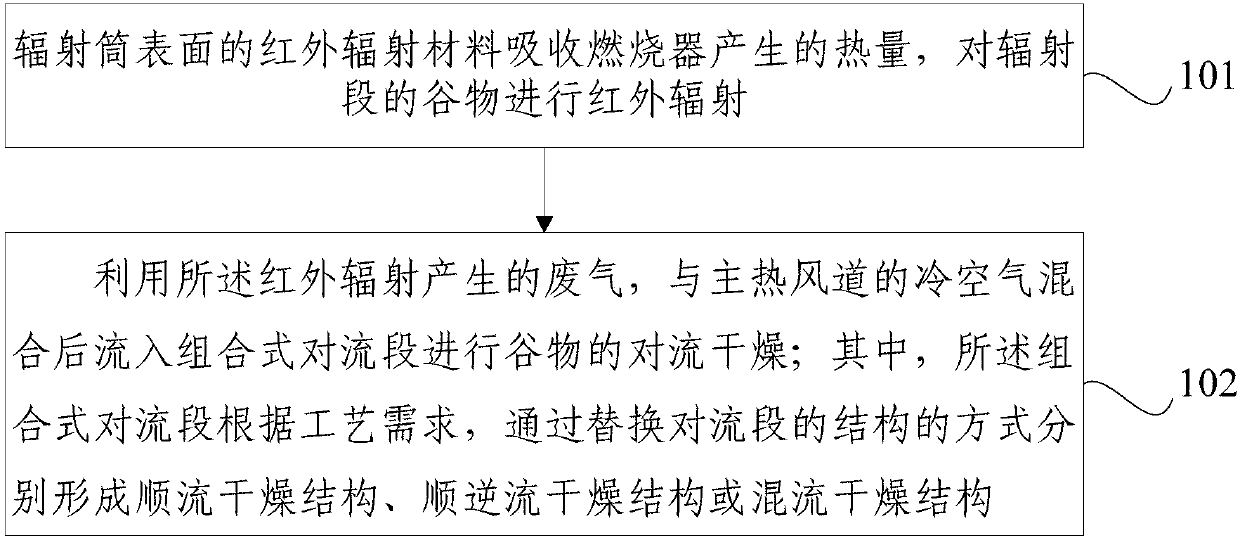

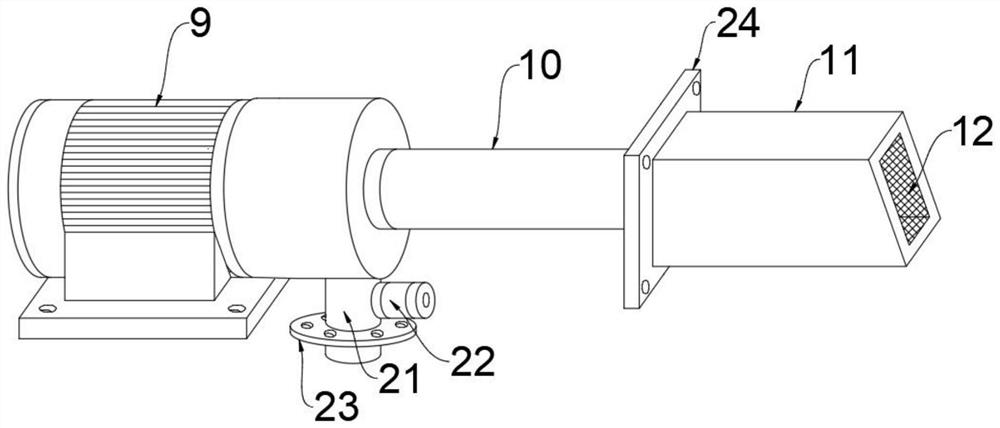

Grain drying method and system

PendingCN107788110AAchieve high efficiency and energy saving effectFood processingSeed preservation by dryingCold airCombustor

The invention provides a grain drying method and system. The method comprises the steps: an infrared radiation material on the surface of a radiation cylinder absorbs heat generated by a burner for carrying out infrared radiation drying on grains in a radiation section; and waste gas generated by the infrared radiation is mixed with cold air of a main hot air duct, and then the mixed gas flows into a combined type convection section for carrying out convection drying on grains. According to the grain drying method and system, the characteristics of infrared radiation and hot air convection combined drying are combined, the waste gas generated after infrared radiation drying is used to be mixed with the cold air of the main hot air duct, and then the mixed gas flows into a combined type convection section for carrying out convection drying on the grains, thereby achieving the effects of high efficiency and energy saving; the combined type convection section of a drying machine adopts acombined design process, is detachable and replaceable, and respectively realizes forward flow drying, forward and back flow drying or mixed flow drying through changing the modes of the combined typeconvection section; and by adopting infrared radiation and hot air convection combined heat drying, the drying rate of the grains in the drying machine is higher and the quality of the grains after drying is better.

Owner:BEIJING UNIV OF POSTS & TELECOMM

An explosion-proof platform lamp

InactiveCN106609948AAchieve high efficiency and energy saving effectSimple structureLighting applicationsMechanical apparatusLight sourceEngineering

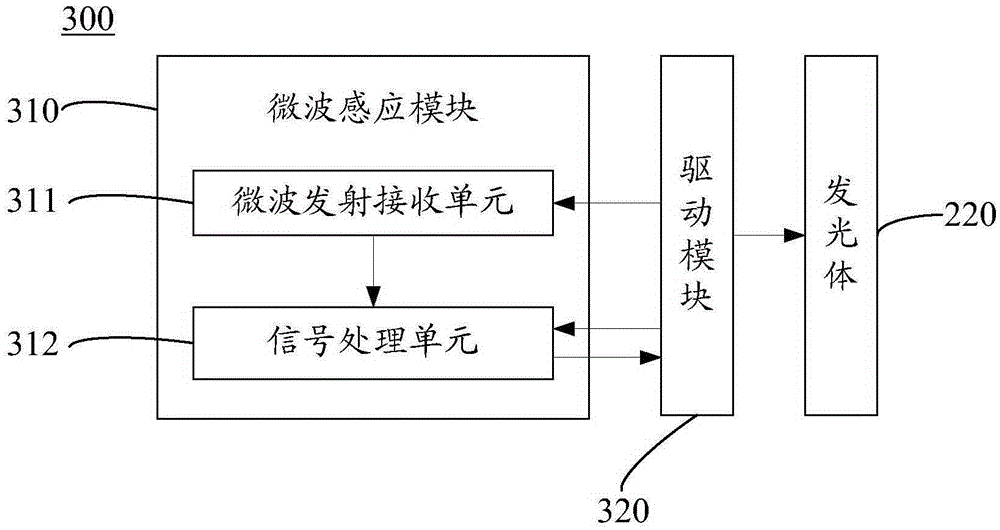

The invention relates to an explosion-proof platform lamp comprising a shell, a light source assembly, and a dimming module. The shell comprises a body and an installing boss, wherein the body is of a columnar hollow structure and the installing boss is arranged at one end of the body; the light source assembly comprises a light reflecting mirror and a light emitting body, wherein the lift reflecting mirror is installed on a side wall of the installing boss and the light emitting body is installed on the light reflecting mirror; the dimming module comprises a microwave sensing module and a drive module, wherein the drive module is located in the body and the microwave sensing module is arranged on the end surface with a smaller diameter of the installing boss. The microwave sensing module is in communication connection with the drive module; the drive module is electrically connected with the light emitting body; the microwave sensing module is used for emitting microwave signals to sense moving objects, receiving and processing microwave signals reflected by the moving objects and sending control signals to the drive module, and thus the drive module can adjust light emitted by the light emitting body. The explosion-proof platform lamp can adjust light emitted by the light emitting body, so that the efficiency is high and energy can be saved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

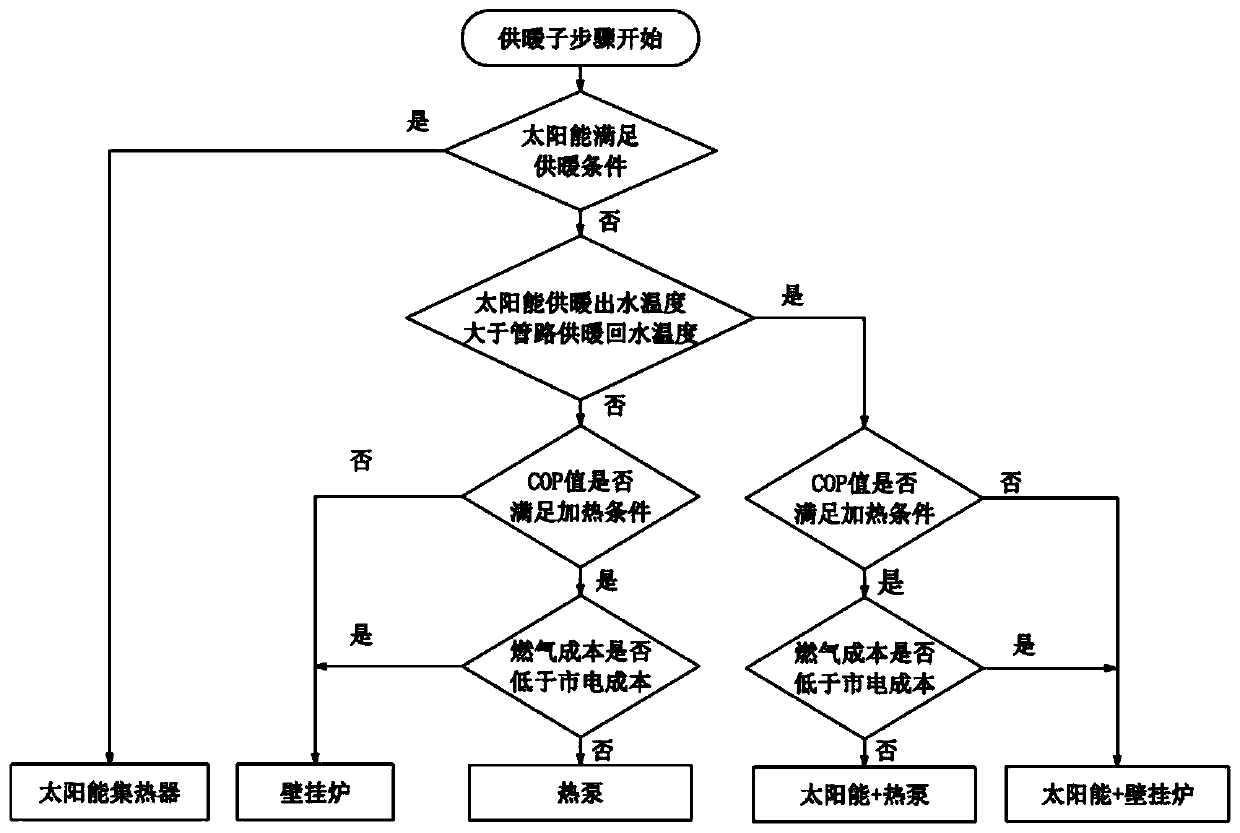

Solar energy wall-hanging boiler heat supply system

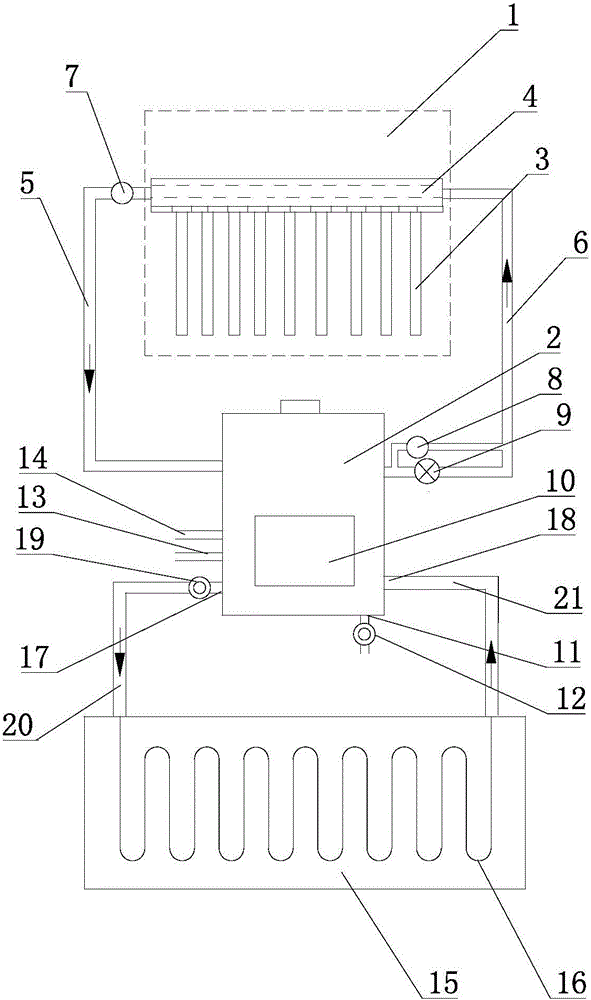

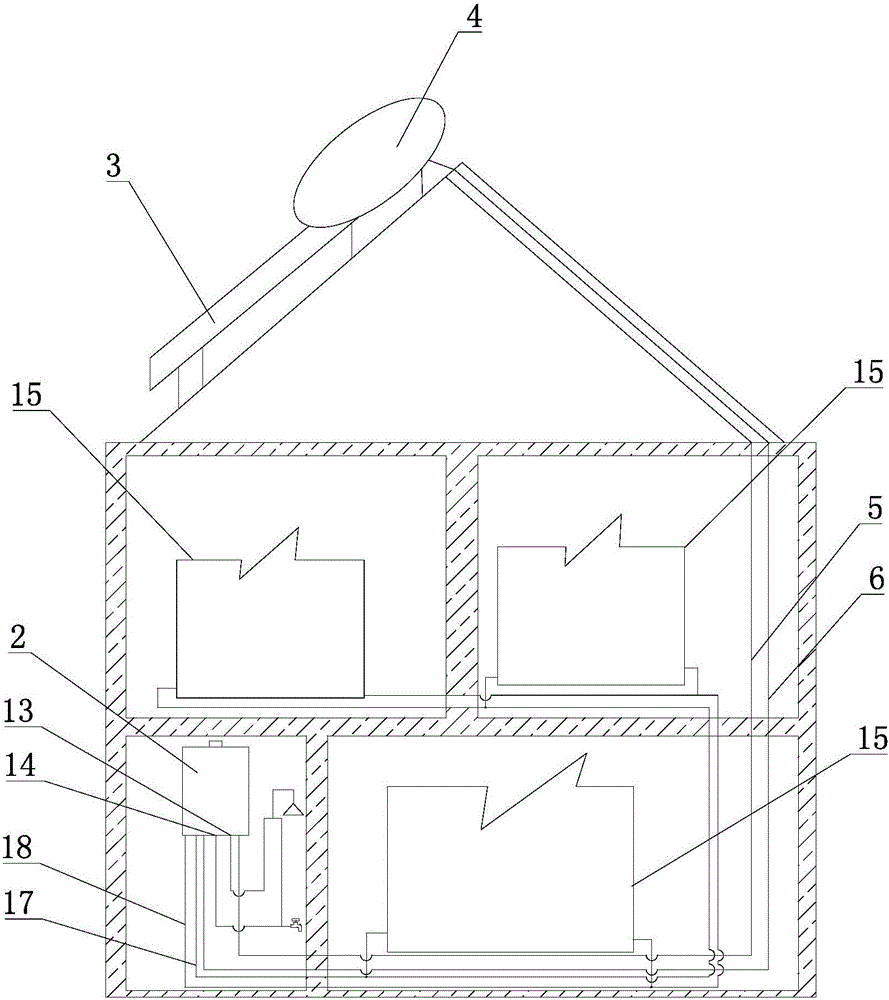

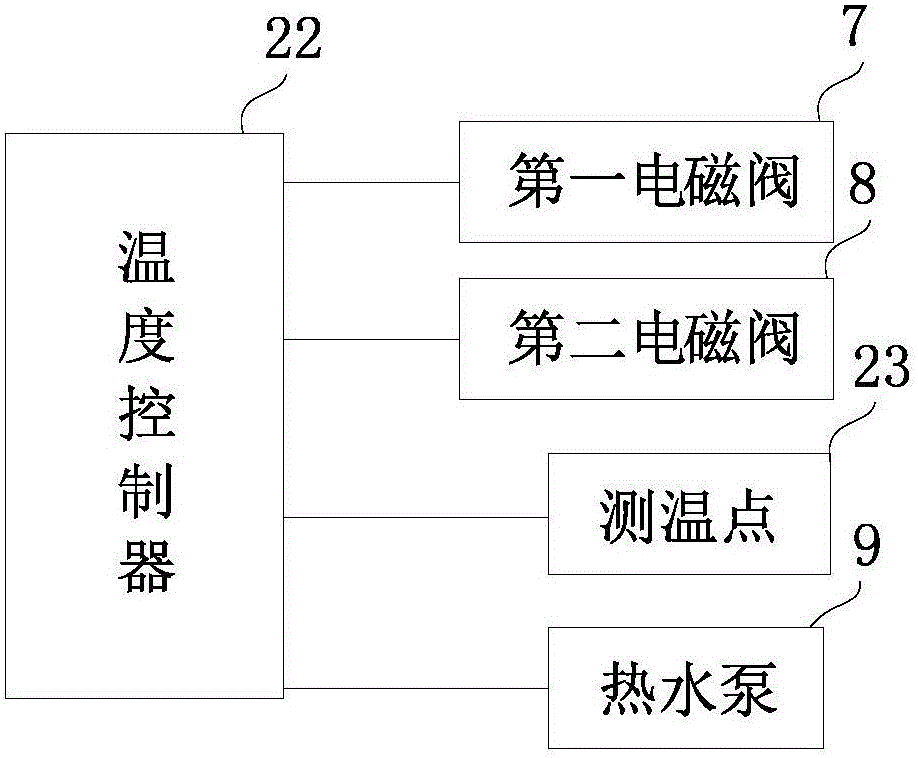

InactiveCN106016418AAchieve high efficiency and energy saving effectGuaranteed operational safetyCovering/liningsLighting and heating apparatusEngineeringHuman–computer interaction

The invention provides a solar energy wall-hanging boiler heat supply system. According to the solar energy wall-hanging boiler heat supply system, the technical problems that the conventional solar energy wall-hanging boiler heat supply system is low in efficiency and wasteful of resources can be solved. The solar energy wall-hanging boiler heat supply system comprises a solar energy heating device and a wall-hanging boiler heating device. The solar energy heating device is connected with the wall-hanging boiler heating device through a water inlet pipe and a water outlet pipe. The solar energy heating device comprises a solar energy heat collector and a solar energy water collector. The wall-hanging boiler heating device is provided with an intelligent control device, a man-machine interaction display screen and a temperature controller. An input end of the intelligent control device is connected with the temperature controller and an output end of the intelligent control device is connected with the man-machine interaction display screen. The system is widely applied to the heat supply field.

Owner:WEIHAI HEGUANG FLOOR CO LTD

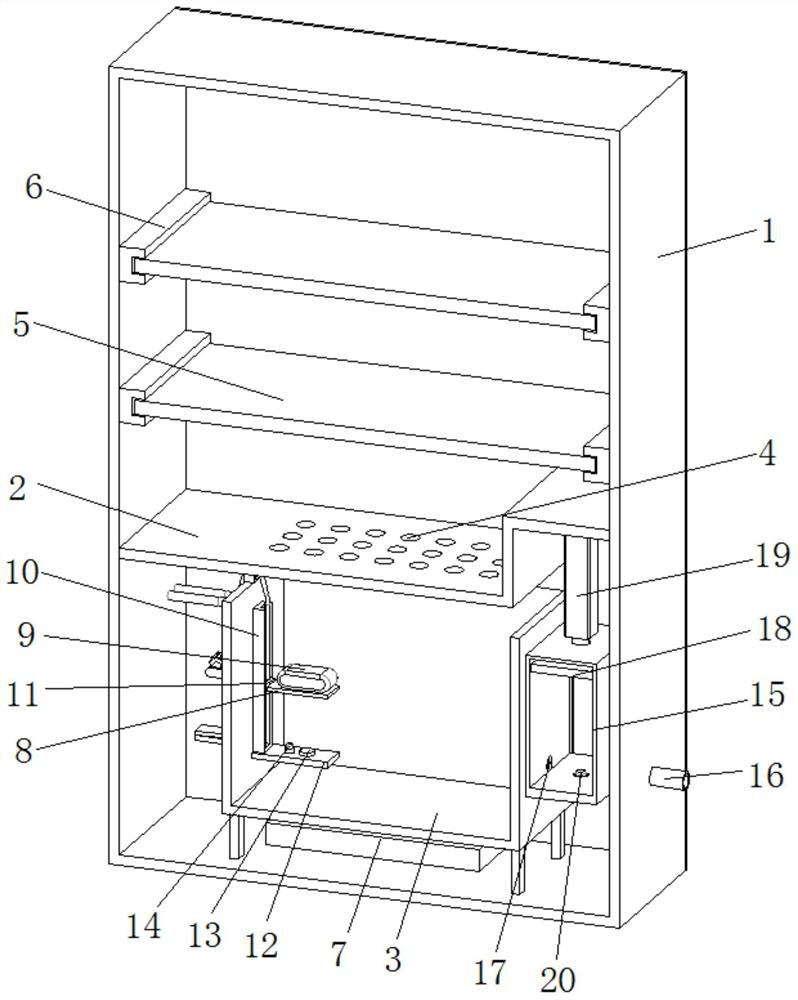

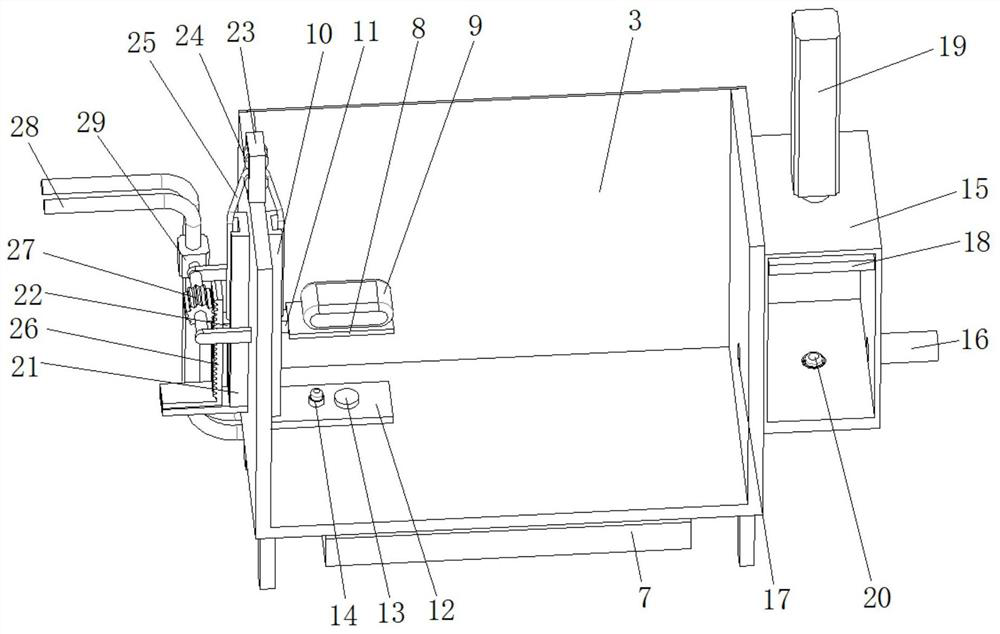

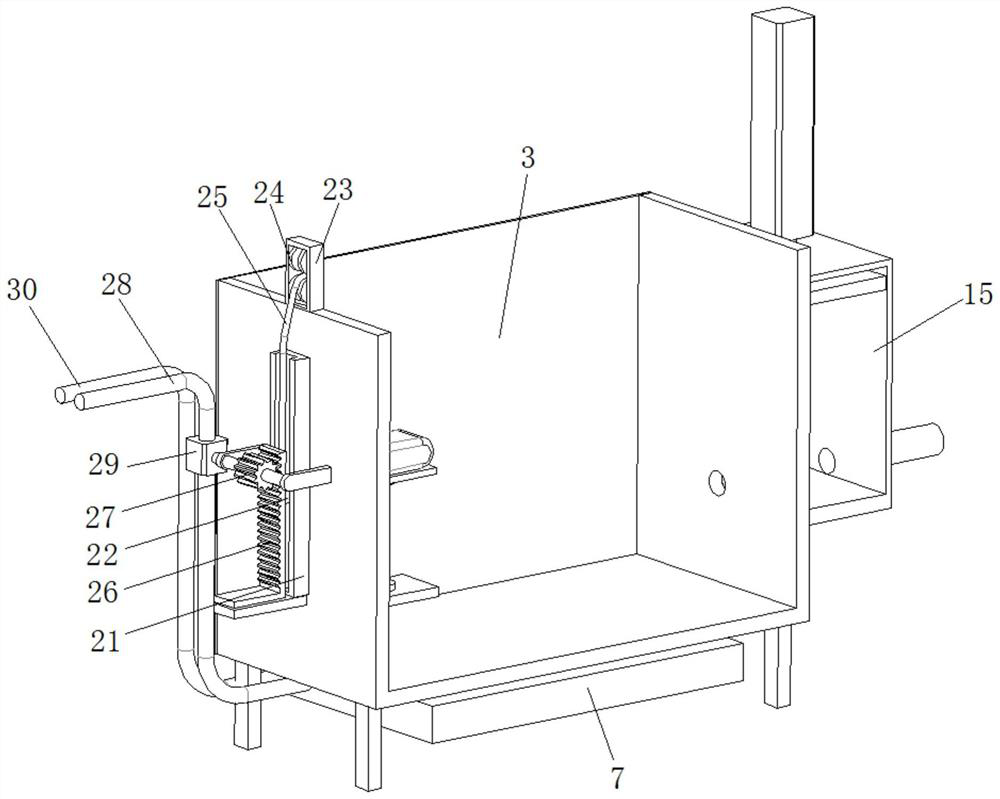

Energy-saving intelligent steam box and using method thereof

ActiveCN111956062ANo manual monitoring requiredClose the gas openingCooking vesselsHydraulic cylinderThermodynamics

The invention provides an energy-saving intelligent steam box and a using method thereof. The energy-saving intelligent steam box comprises a box body, a partition plate, a water tank, a plurality ofsteaming racks and heating stoves, the partition plate is arranged below the inner cavity of the box body, compact through holes are formed in the partition plate, the two ends of the steaming racks are connected with the box body in a sliding mode through sliding rails, the multiple steaming racks are vertically arranged above the partition plate at equal intervals, the water tank is arranged inthe inner cavity of the box body and located below the partition plate, and the heating stove is used for heating the water tank. When a support plate at the bottom of the floating ball contacts the bottom plate, electromagnets between the two can attract each other, meanwhile, the supporting plate presses the hydraulic cylinder switch to actuate a hydraulic cylinder, the hydraulic cylinder pushesthe piston to press water in the water tank into the water tank for water supplementation, when water supplementing is completed, the piston reaches the bottom of the water tank, the piston triggersthe power-off switch to enable the electromagnets to be separated from each other, the floating ball on the supporting plate floats upwards to the water surface, meanwhile, the hydraulic cylinder switch is loosened to enable the hydraulic cylinder to reset, and compared with the prior art, the energy-saving intelligent steam box can automatically supplement water along with water level lowering.

Owner:绍兴市载沣智能科技有限公司

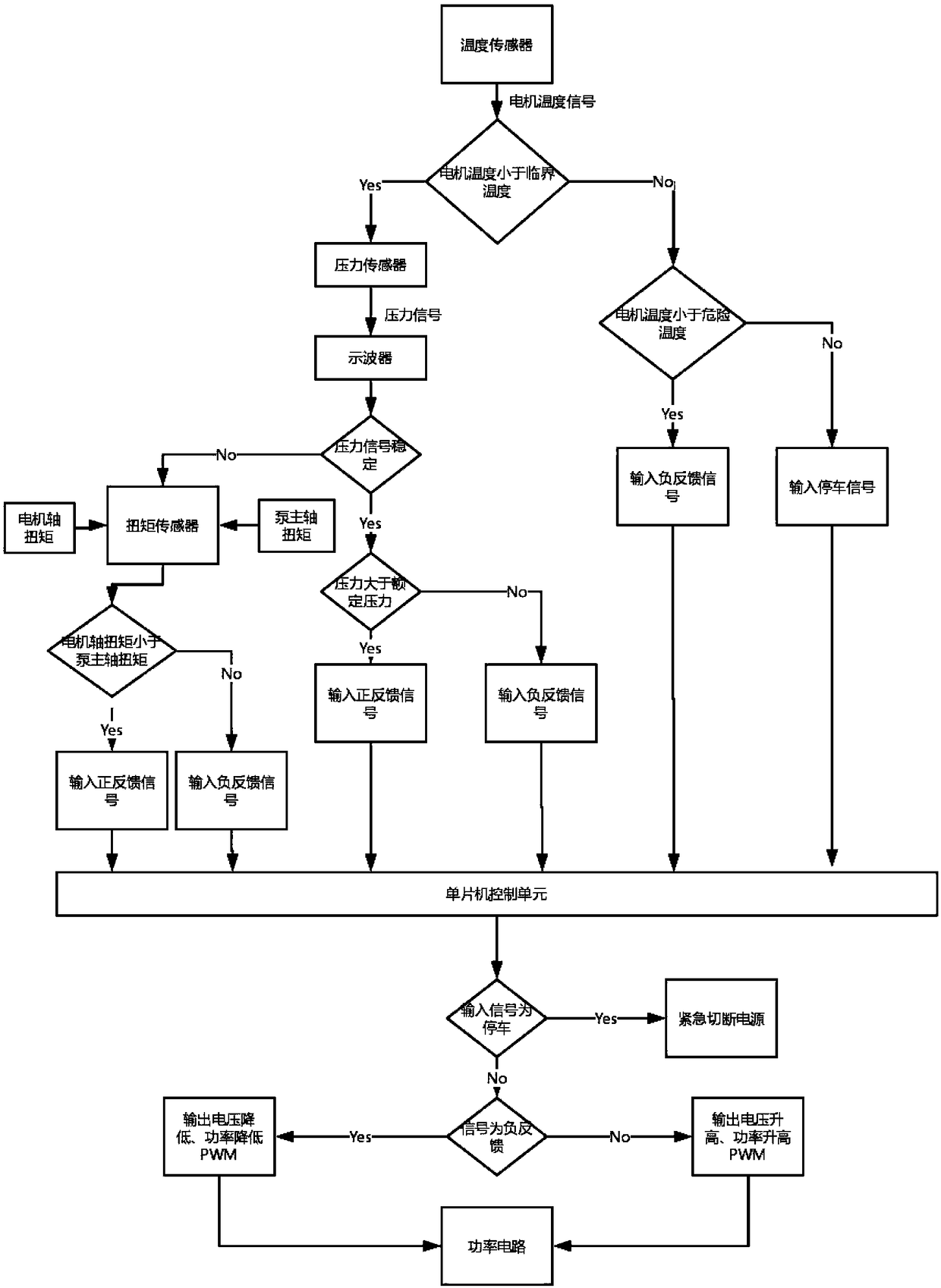

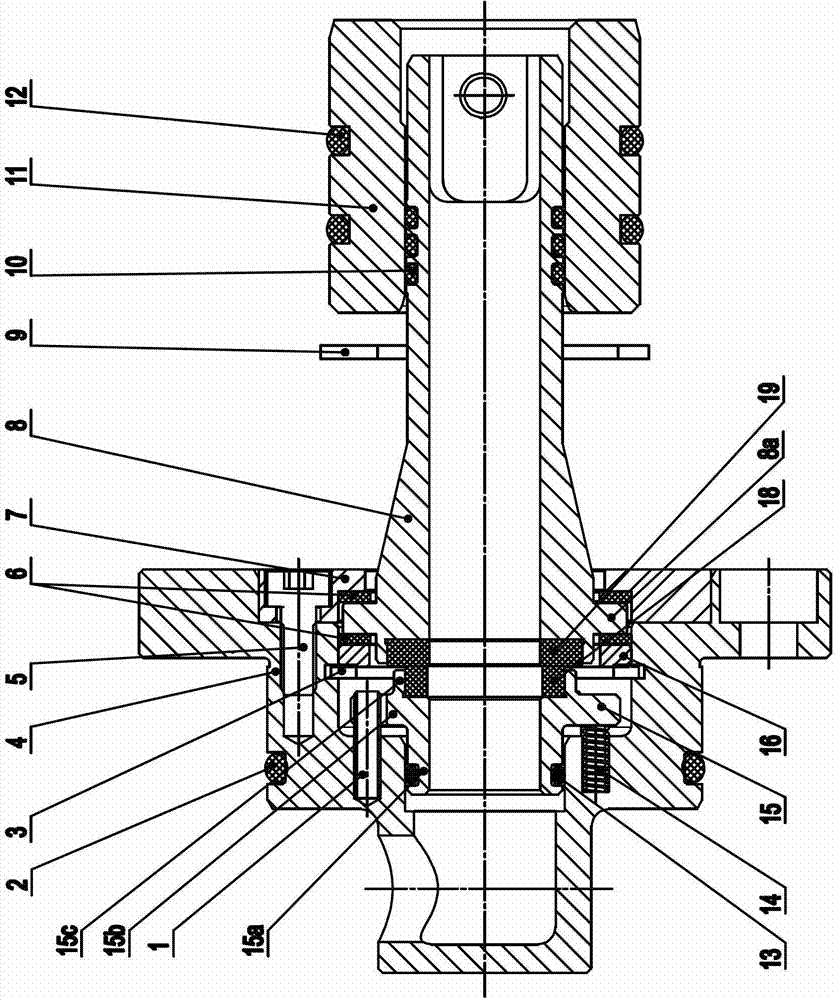

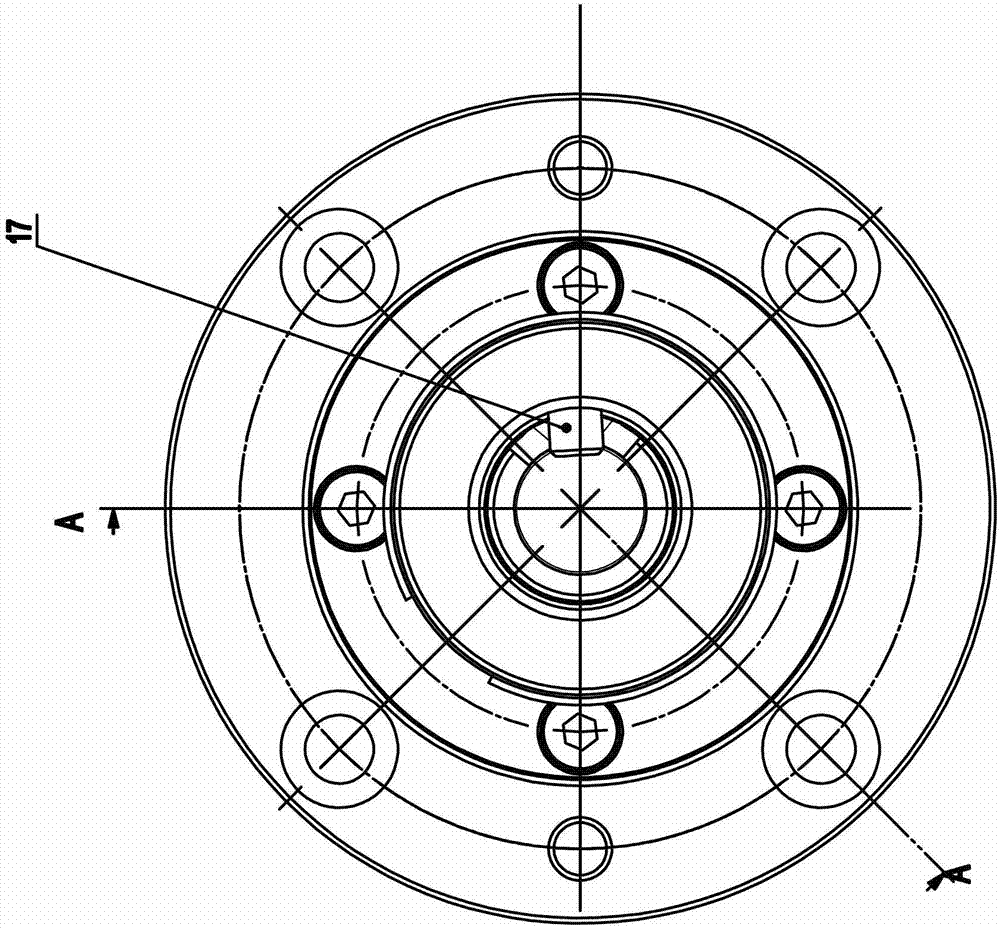

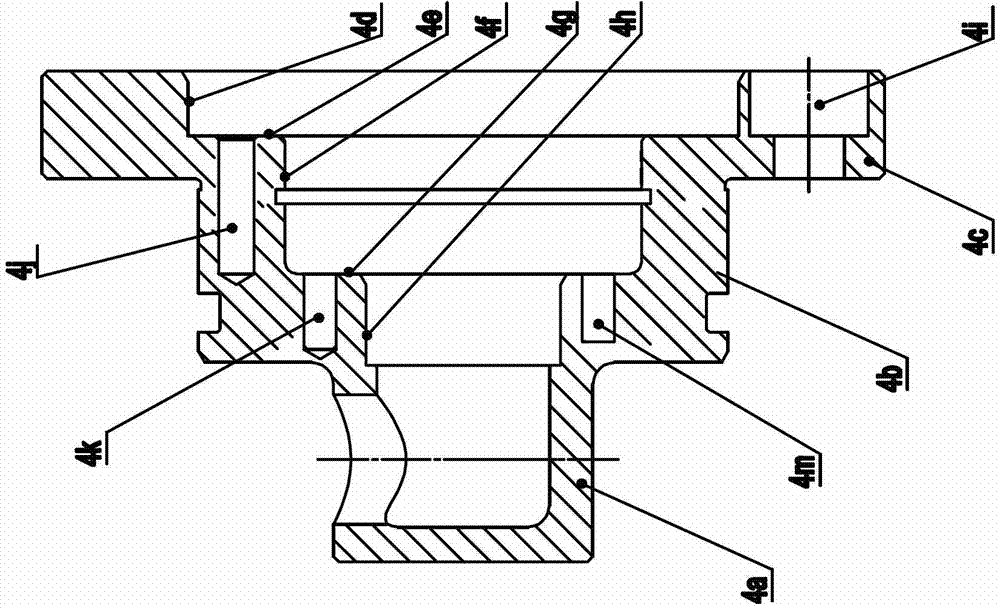

Centrifugal pump and permanent magnet synchronous motor matching device and monitoring, regulating and controlling method thereof

PendingCN108488076AControl operationEasy to controlTorque ripple controlPump controlElectric machinePermanent magnet synchronous motor

The invention provides a centrifugal pump and permanent magnet synchronous motor matching device and a monitoring, regulating and controlling method thereof. The centrifugal pump and permanent magnetsynchronous motor matching device comprises a centrifugal pump, a permanent magnet synchronous motor and a servo driver. An impeller is arranged in a pump cavity of a pump shell of the centrifugal pump, and a pump shaft fixedly penetrating the center of the impeller stretches out of the pump shell. The pump shell is provided with a water inlet and a water outlet, and the water outlet is sequentially connected with an oscilloscope and a pressure sensor in series. The signal output end of the pressure sensor is connected with the servo driver through a wire. A stator and a rotor are arranged ina motor shell of the permanent magnet synchronous motor. A motor shaft fixedly penetrating the center of the rotor stretches out of the motor shell. The motor shell is provided with a temperature detector and a rotation speed sensor, and the signal output end of the temperature detector and the signal output end of the rotation speed sensor are connected with the servo driver through wires. A torque sensor is arranged between the drive end of the motor shaft and the transmission end of the pump shaft, the signal output end of the torque sensor is connected with the servo driver through a wire,and the servo driver is connected with the permanent magnet synchronous motor through a frequency converter in an electric control manner.

Owner:ZHEJIANG YONGFA ELECTROMECHANICS LTD

Efficient cooling swivel joint

ActiveCN102927391AIngenious design structureImprove cooling effectAdjustable jointsRevolute jointEngineering

The invention relates to an efficient cooling swivel joint comprising a stop pin, a check ring for a first hole, a shell, a cover, an outer tube, a second O-shaped ring, a transition sleeve, a fourth O-shaped ring, a small spring, a stationary seal ring, a round pin, a static sealing ring and a motive sealing ring. The designed structure is ingenious; the original single spring blocking liquid inlet is eliminated, and the cooling medium is unobstructed, so that the cooling medium of the fully-embedded swivel joint is not blocked to cause leakage; the cooling liquid turn volume is increased by 1.5 times at the same diameter joint; the cooling effect is increased by 75%; and the efficient energy-saving effect is achieved. Multiple springs and a balanced sealing design are adopted to enable the stress at a sealing surface to be uniform and self-balanced, reduce the failure rate, and prolong the service life. A plurality of radial through holes are arranged on the thin section of the shell; the liquid inlet is smoother; and the phenomenon of blocking the liquid inlet port is completely eradicated. A outer tube cantilever beam stress part is configured as a thickened taper structure, so that the strength of the outer tube is increased, and fatigue break of the outer tube is completely eradicated.

Owner:TENGXUAN TECH

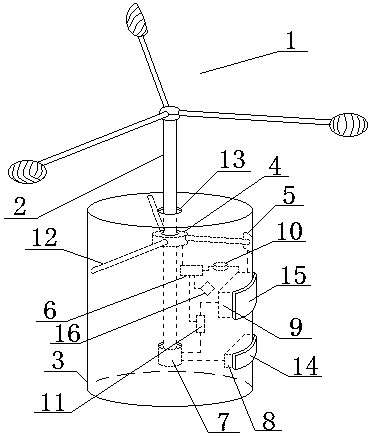

An intelligent power supply delay wind speed meteorological sensor

InactiveCN106199068BAchieve high efficiency and energy saving effectGuarantee job stabilityAcceleration measurement using interia forcesElectricityCapacitance

The invention relates to an intelligent power supply delay wind speed meteorological sensor. The sensor synchronously obtains the detection operation of a three-cup wind rotating device (1) through a design structure of a conductive fixed ring (4) and a conductive rotating rod (12), and combines with the design of an elastic conductive piece (5) to achieve the triggering operation of a high-frequency signal through a power supply module (9). The continuous power supply mode of a storage capacitor (10) is introduced, and the sensor achieves the instant power supply of a designed rotating sped sensor (7) based on the instant control closed operation of a motor electric control switch (11) through cooperating with the delay switching-off operation of a designed timing circuit (16). The sensor captures a wind speed detection result, generated by the three-cup wind rotating device (1) through an insulating transmission rod (2), through the operation of the designed rotating sped sensor (7). A long-term continuous power supply scheme for the rotating sped sensor (7) is cancelled, thereby achieving the high-efficiency energy-saving effect of the wind speed sensor while guaranteeing the operation stability.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

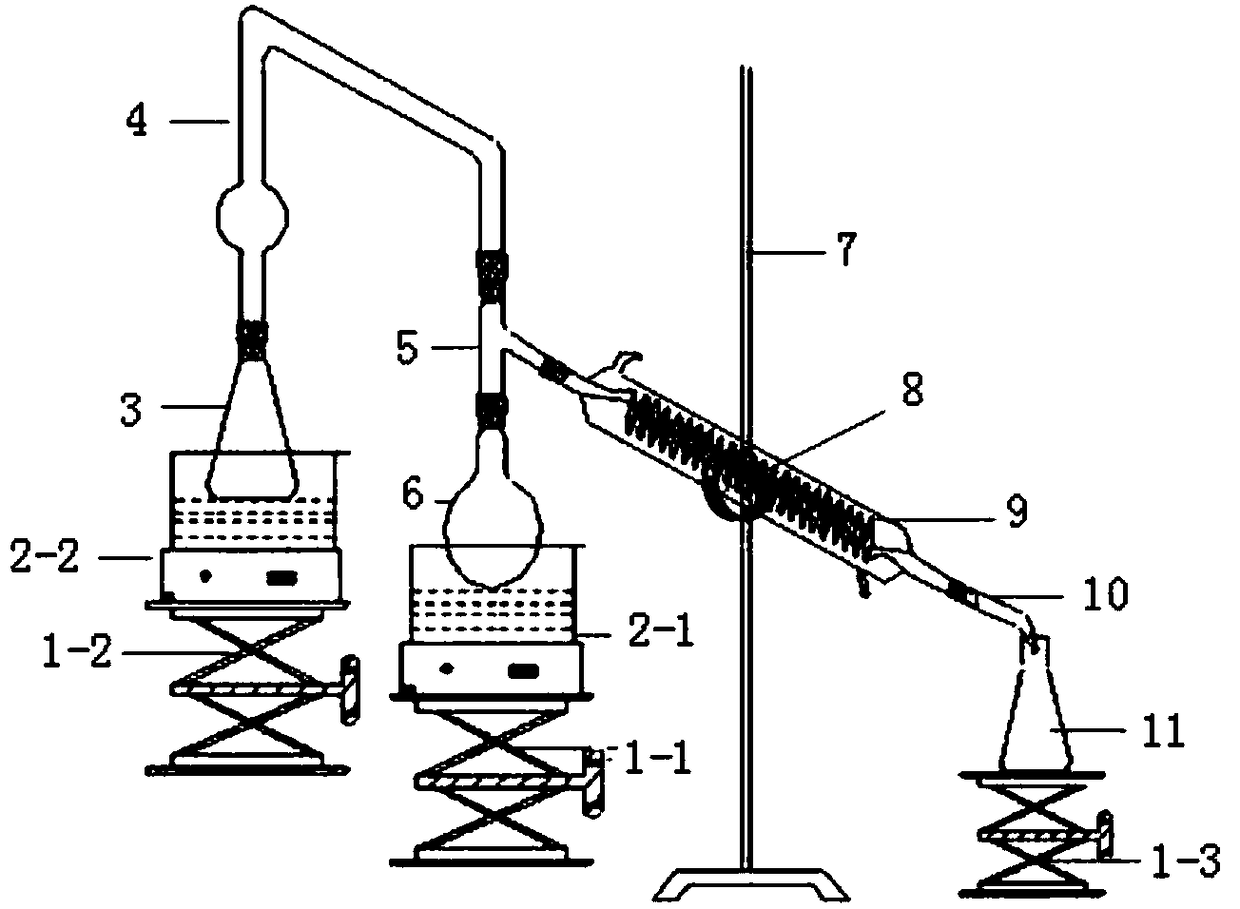

Method for preparing ethanol with ultralow metal ion concentration

InactiveCN108178722ATake advantage ofImprove thermodynamic efficiencyOrganic compound preparationHydroxy compound preparationFermentationMetal

The invention discloses a method for preparing ethanol with ultralow metal ion concentration. Absolute ethanol produced from tapioca flour through fermentation is taken as a raw material and processedwith a heating reflux method, an ethanol liquid is distilled off in a sub-boiling state, and metal ions in ethanol is removed. The metal ion concentration of purified ethanol is ultralow and is tested and verified by a Perkin Elmer-PinAAcle 900T type atomic absorbing instrument. The method has the beneficial effects as follows: the method and equipment for improving purity of ethanol by a simpledevice are invented, chemical development is promoted, and particularly, the method has great significance for promoting production and popularization of electronic grade ethanol.

Owner:GUANGXI COFCO BIO ENERGY

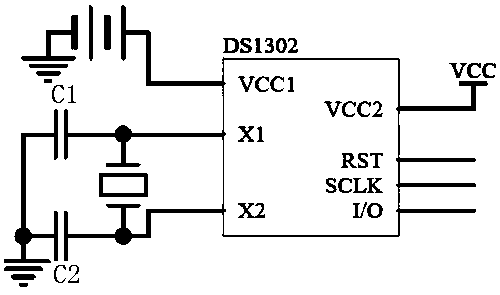

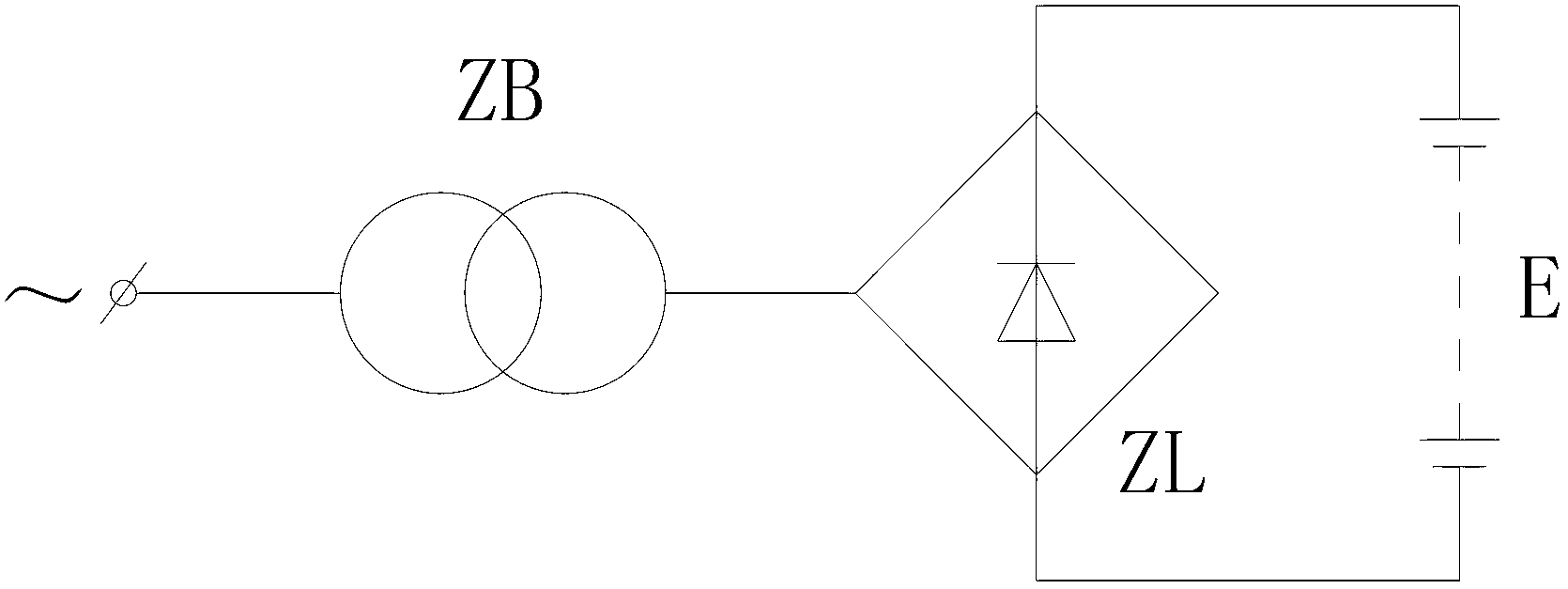

Energy-saving charger

InactiveCN102709999AGuaranteed service lifeAchieve high efficiency and energy saving effectBatteries circuit arrangementsEmergency protective circuit arrangementsIn vehicleCapacitance

The invention discloses an energy-saving charger, which comprises a voltage-reducing current-stabilizing circuit, an earth leakage circuit breaker and a rectifier, wherein the earth leakage circuit breaker as a master power switch is respectively connected to a live line and a zero line of a power supply; the pressure-reducing and current-stabilizing circuit is connected with multiple groups of capacitors with different capacities in parallel and then connected to the live line of the power supply in series; and the input end of the rectifier is respectively connected with a power zero line controlled by the earth leakage circuit breaker and the power fire line which is controlled by the earth leakage circuit breaker and connected with the capacitor group in series, and the output end of the rectifier is connected to a storage battery to be charged for realizing charging. According to the energy-saving charger, two ends of a test button of the earth leakage circuit breaker are led out by wires and are connected with normally-opened auxiliary contact points of a sampling controller and a no-load protector to realize the functions of no-load protection and automatic poweroff when the storage battery is completely charged, and output current of the charger is changed by a universal conversion switch, therefore charging requirements of different specifications of storage batteries can be met. The energy-saving charger disclosed by the invention can be widely applicable to charging of storage batteries in vehicle repair plants, motorcades, storage battery business departments and electric vehicles.

Owner:贵州天昱金泰电力建设工程有限公司

Energy saving wind speed meteorological sensor device

InactiveCN106199058AAchieve high efficiency and energy saving effectGuarantee job stabilityFluid speed measurementElectricityCapacitance

The invention relates to an energy saving wind speed meteorological sensor device. Novel structure design is used. A mechanical trigger power supply mechanism is introduced. The detection of a three-cup type wind rotation device (1) is synchronously acquired through the design of a conductive fixation ring (4) and a conductive rotating rod (12). The trigger action of a high-frequency signal is realized through a power supply module (9) in combination with the design of a flexible conductive piece (5). A storage capacitor (10) is introduced for continuous power supply. Real-time power supply for a designed rotation speed sensor (7) is realized based on the instant control closing action and the delay opening action for a motor electronic control switch (11). Through the operation of the rotation speed sensor (7), a wind speed detection result which is detected by the three-cup type wind rotation device (1) through an insulation transmission rod (2). A long-term continuous power supply scheme for the rotation speed sensor (7) is cancelled. The wind speed sensor has the advantages of stable work, high efficiency and energy saving.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

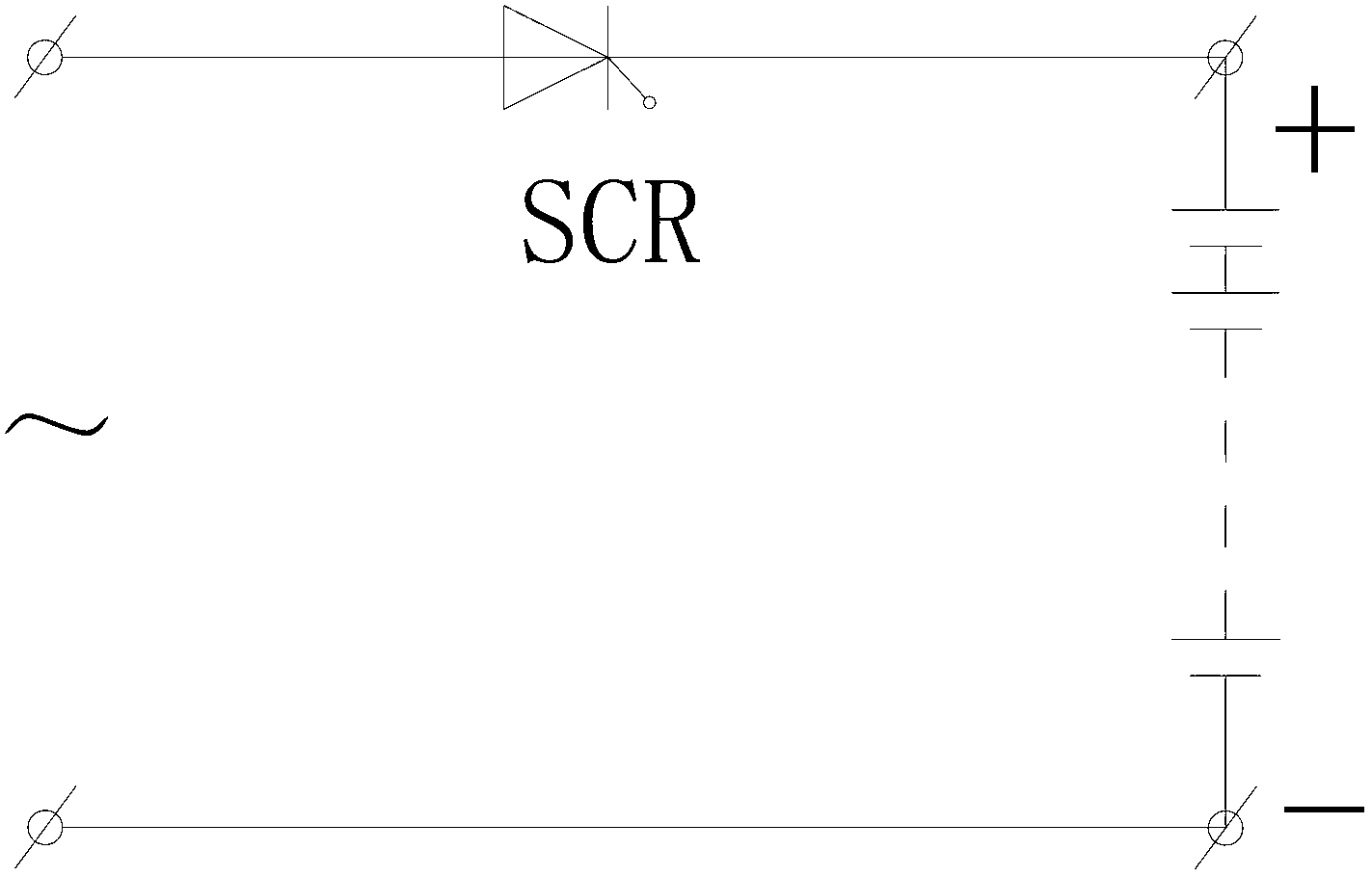

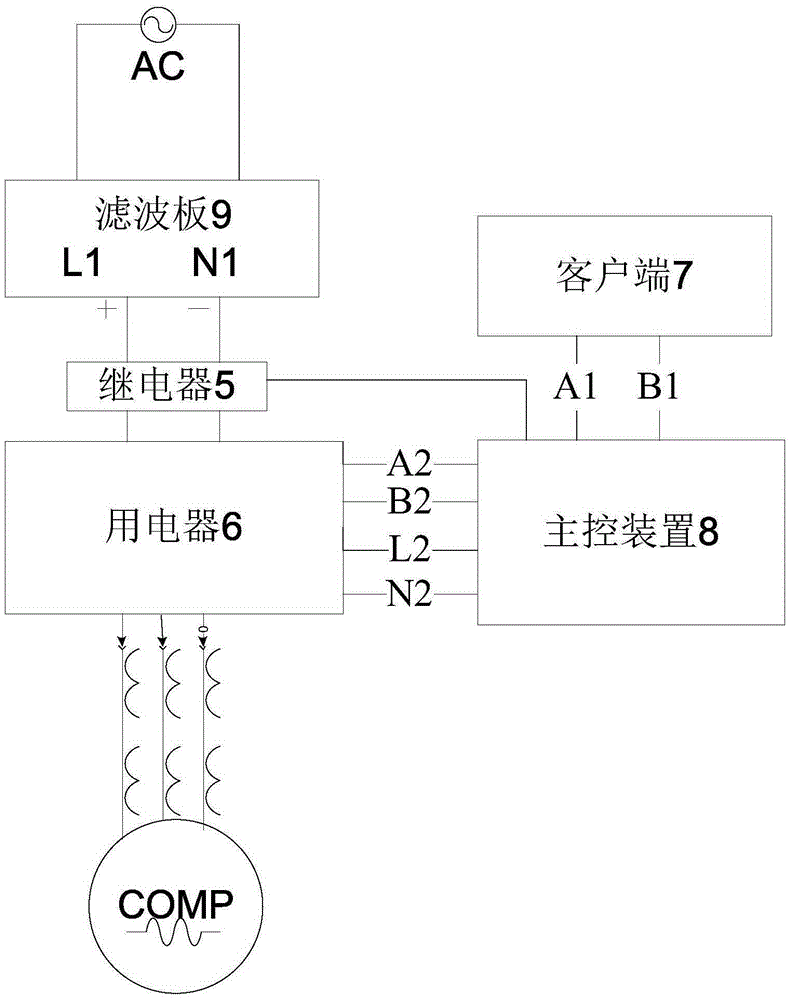

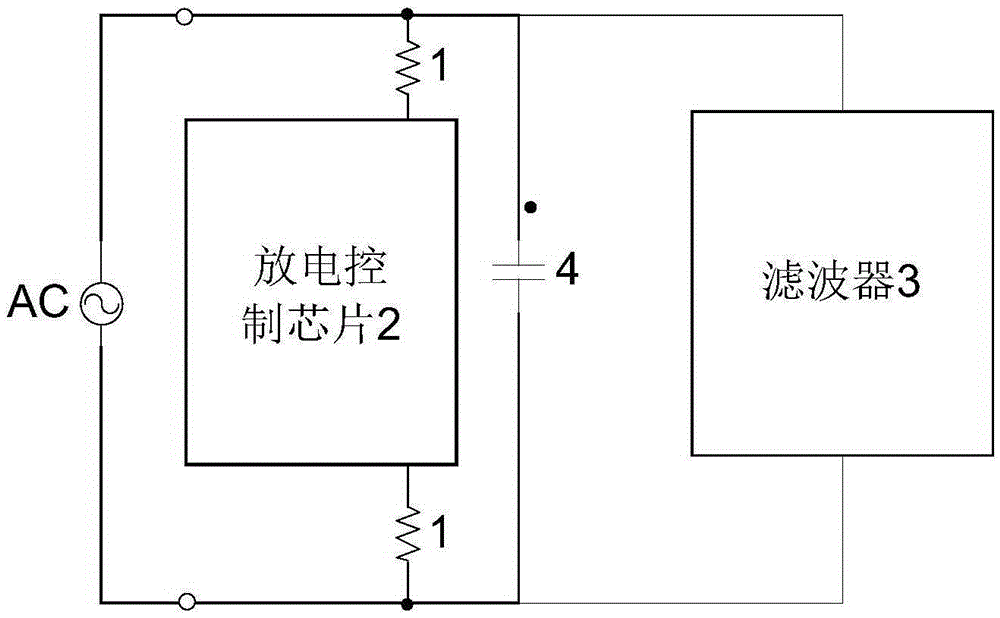

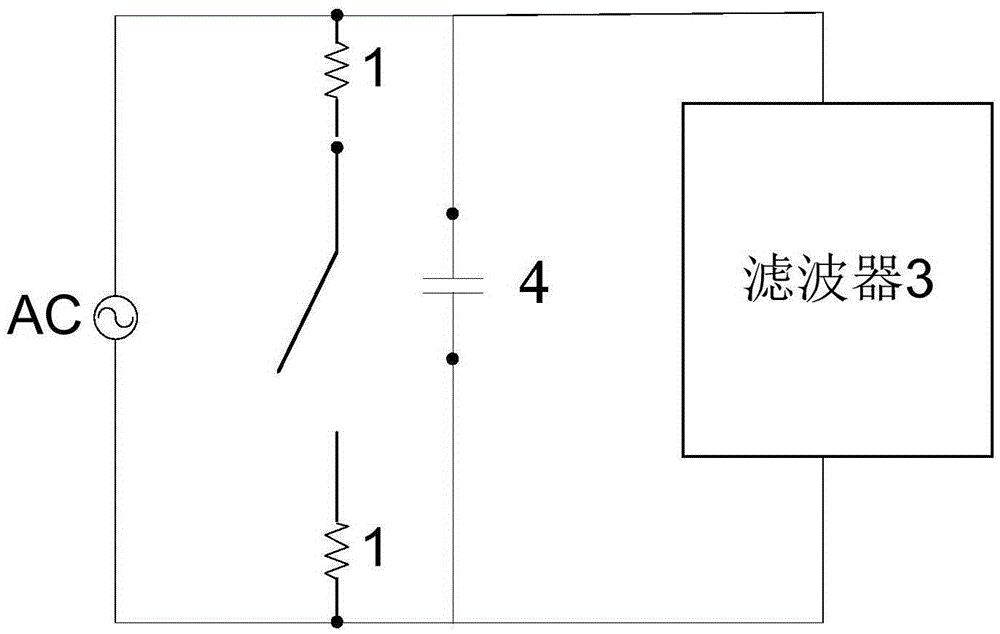

Standby control circuit, standby control method and electrical apparatus

ActiveCN105302214AReduce standby power consumptionAchieve high efficiency and energy saving effectElectric variable regulationStandby powerControl circuit

The invention discloses a standby control circuit, a standby control method and an electrical apparatus. The standby control circuit comprises discharging resistors, a discharging control chip, a filter and an X-capacitor, wherein the discharging control chip and the discharging resistors are in series connection so as to form a discharging circuit; the discharging control chip is used for controlling the connection of the discharging circuit when an input AC power supply is powered off; the X-capacitor is used for filtering differential mode interference; and the X-capacitor is in parallel connection with the discharging circuit and the filter. By employing the technical scheme mentioned above, the discharging control chip can control the working state of the discharging resistors, so that the standby power consumption is saved, efficient and energy-saving effects are achieved, and the standby control circuit is simple in structure and low in cost.

Owner:GREE ELECTRIC APPLIANCES INC

Efficient booster-type vacuum pump

InactiveCN103899545AGuaranteed to workAchieve high efficiency and energy saving effectPump componentsPump installationsEngineeringDiesel engine

The invention discloses an efficient booster-type vacuum pump. According to the principle of a diesel engine supercharger, action is performed on a turbine directly through stem, and the speed is 80000rpm around; a compressing wheel produces strong suction to form the vacuum environment of the air in equipment. Owing to the ultra high speed, a floating bearing is adopted and drives lubricating oil during operation, and protective oil film is produced on the periphery of the floating bearing; the lubricating oil is delivered to a lubricating system through an arranged electric oil pump to guarantee normal operation; the diameter of the turbine of a steam turbine is smaller than that of the compressing wheel of an air compressing system, so that the compressing wheel is capable of exhausting large quantity of air through small quantity of steam, and efficient energy-saving effect is achieved.

Owner:BEIJING ZHONGTIAN JINGU GRAIN OIL ENG TECH

Energy-saving ship power transmission device

PendingCN113525653AEfficient power generationAchieve high efficiency and energy saving effectPropulsion power plantsHydro energy generationPropellerDrive shaft

The invention discloses an energy-saving ship power transmission device, which relates to the technical field of ship power transmission devices, and aims at solving the problems that an existing solar and wind power generation ship is easily influenced by environment and weather factors, the energy conversion rate is large in floating, and a large space of a ship body is occupied. Two main power motors are installed on the two sides of the rear end of the ship storage battery correspondingly, first transmission shafts are installed at the output ends of the two main power motors correspondingly, one ends of the first transmission shafts are fixedly connected with the output ends of the main power motors through first couplings, A gear reducer is installed at the other end of the first transmission shaft, a second transmission shaft is installed at the output end of the gear reducer, one end of the second transmission shaft is fixedly connected with the output end of the gear reducer through a second coupler, a propeller sleeve is installed at the other end of the second transmission shaft, and a bearing seat is mounted on the second transmission shaft.

Owner:江苏省无锡交通高等职业技术学校

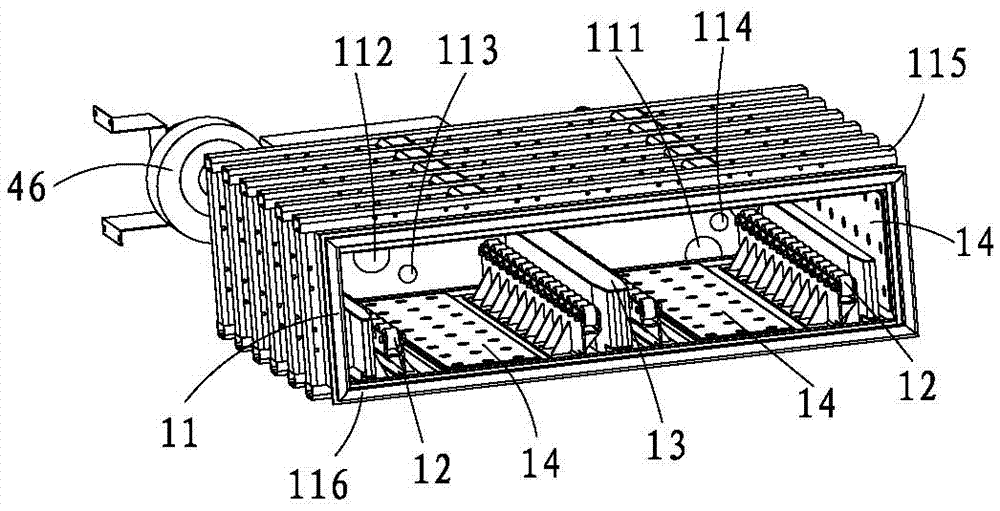

A power battery vacuum drying equipment

ActiveCN104567292BEasy to moveRealize automatic feedingDrying gas arrangementsDrying chambers/containersPower batteryEngineering

The invention belongs to the technical field of drying equipment, and particularly relates to a power battery vacuum drying equipment, which includes a box body, a furnace cavity arranged in the box body, a furnace door mechanism matched with the furnace cavity, and a The air transport system and the control part arranged on the side of the box body, the furnace cavity includes a furnace cavity body, a loading track, a loading tray isolation plate and a mica sheet, and the loading track and the loading tray are isolated Both the plate and the mica sheet are arranged in the furnace cavity body. The invention realizes the automatic charging of electric cores, improves the drying efficiency and drying effect, reduces the power consumption of equipment, and achieves the effect of high efficiency and energy saving.

Owner:DONGGUAN POWERAMP TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com