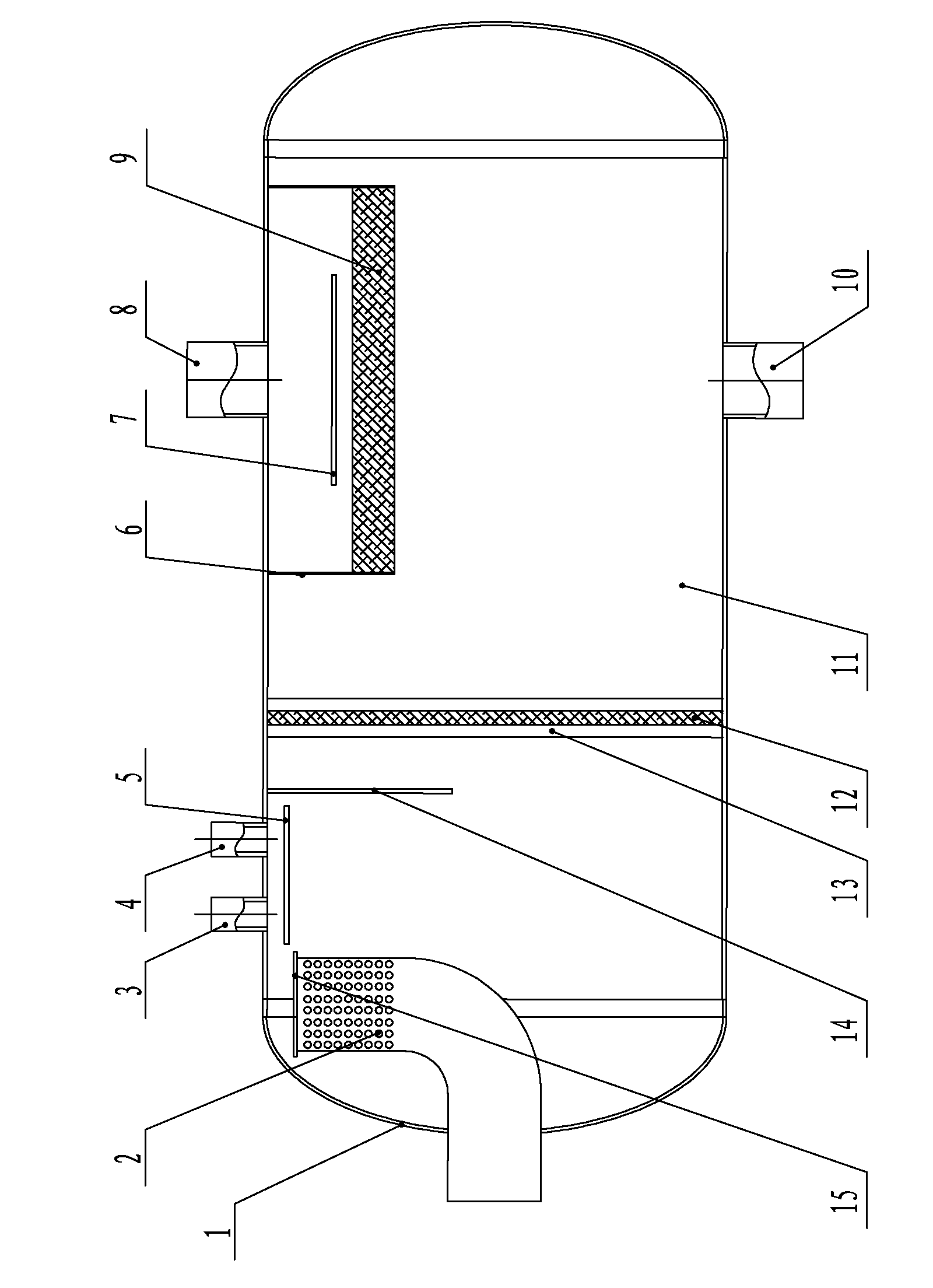

Horizontal flash tank for centrifugal unit

A flash tank and centrifugal technology, which is applied in the internal structure of central air-conditioning centrifugal units, can solve problems such as flash tank liquid level fluctuations and compressor damage, and achieve the effects of increasing energy efficiency ratio, improving cooling capacity, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Such as figure 1 As shown: the inlet pipe 2 and the head 1 are welded deep into the interior, the direction of the inlet pipe 2 is upward, the end of the inlet pipe 2 is drilled, and the drilling area is twice the area of the inlet pipe, and the port is welded with a blocking plate ; The liquid spray return port 3 and the oil cooling liquid return port 4 are welded with the shell 11 in the circumferential direction, and an anti-shock baffle 5 is added to the outlet; a distance from the anti-shock baffle 5 is welded to the right side of the baffle 14; After the plate 13 and the primary filter screen 12 are fixed, they are sealed and welded with the housing 11; the suction baffle 7 and the housing 11 are welded directly below the air outlet 8; The body 11 is sealed and welded, symmetrically installed below the gas outlet 8, the liquid outlet 10 is below the housing 11, and the gas outlet 8 is above the housing 11; the liquid inlet pipe 2, the liquid spray return port 3,...

Embodiment 2

[0021] The area of the hole drilled at the end of the liquid inlet pipe 2 is three times the area of the liquid inlet pipe, and the liquid spray return port 3 and the oil cooling liquid return port 4 are axially welded to the housing 11, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com