Method for preparing ethanol with ultralow metal ion concentration

A technology of metal ion concentration and ion concentration, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., to achieve the effect of less ethanol impurity content and improved thermodynamic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing ethanol with ultra-low metal ion concentration, according to the following steps:

[0021] 1. Take anhydrous ethanol produced from cassava flour, add potassium sulfate, sodium sulfate, and copper sulfate aqueous solution to prepare an ethanol solution with a potassium, sodium, and copper ion concentration of 20 ppm. It can be considered that the solution contains potassium, sodium, and copper. The ion concentration is at least 20 ppm.

[0022] 2. Use PinAAcle 900T atomic absorption analyzer to test and analyze the exact concentration of potassium, sodium and copper ions in the above solution: potassium ion concentration is 20.70ppm, sodium ion concentration is 21.81ppm, copper ion concentration is 20.42ppm, and the data is recorded.

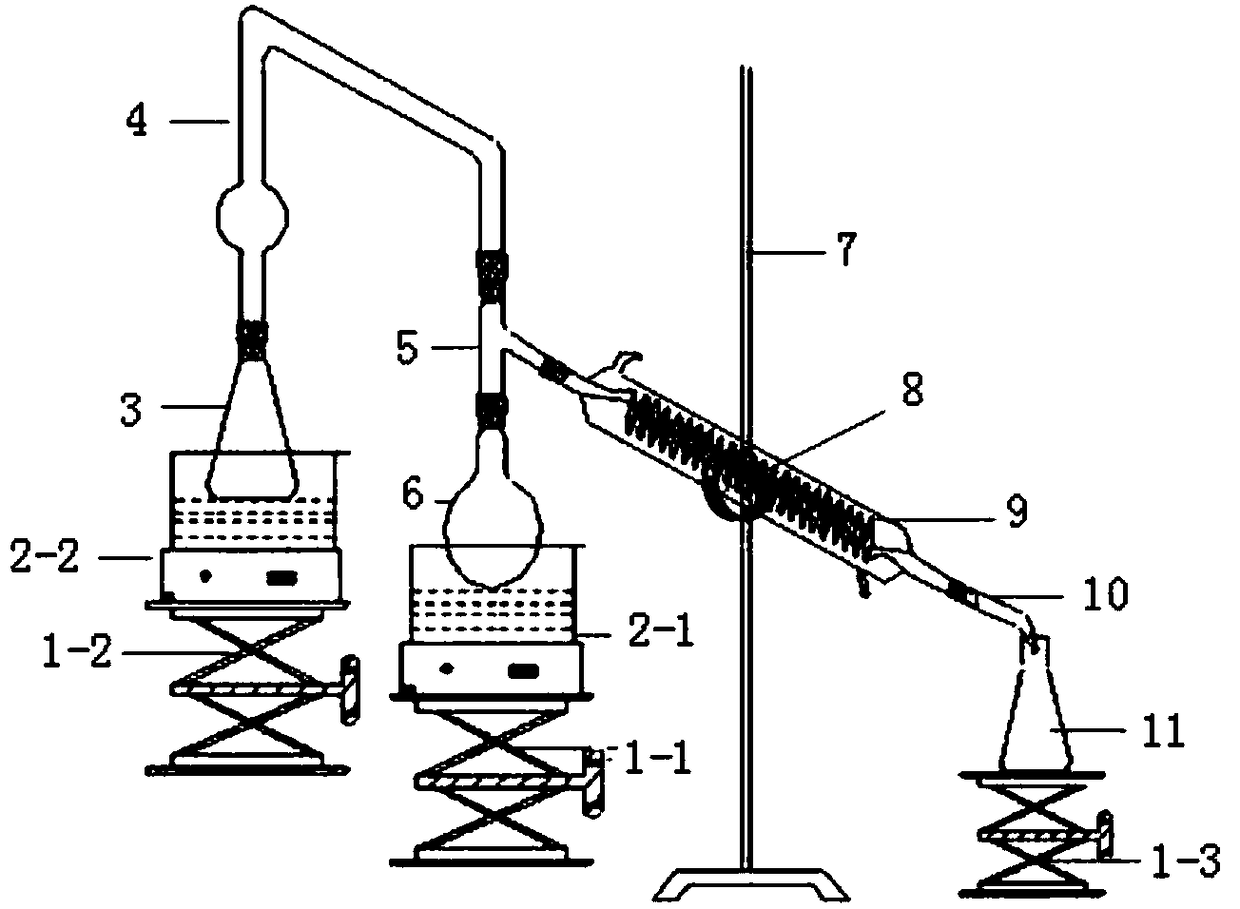

[0023] 3. Install the preparation device: connect one end of the condenser 9 to the T-end of the tee 5, and the other end to the receiving flask 11 through the horn tube 10; one end of the straight tube of the tee 5 is conn...

Embodiment 2

[0028] A method for preparing ethanol with ultra-low metal ion concentration, according to the following steps:

[0029] 1) Take the absolute ethanol produced from cassava flour, add potassium sulfate, sodium sulfate, and copper sulfate aqueous solution to prepare an ethanol solution with a potassium, sodium, and copper ion concentration of 10 ppm. It can be considered that the solution contains potassium, sodium, and copper. The ion concentration is at least 10 ppm.

[0030] 2) Test and analyze the exact concentration of potassium, sodium and copper ions in the above solution with PinAAcle 900T atomic absorption analyzer: potassium ion concentration is 10.34ppm, sodium ion concentration is 11.38ppm, copper ion concentration is 10.74ppm, and the data is recorded.

[0031] 3. Same as Example 1.

[0032] 4. Put the solution described in step 1 in round-bottom flask 6 for distillation, and the distillate is then subjected to sub-boiling distillation in Erlenmeyer flask 3. The distillatio...

Embodiment 3

[0036] A method for preparing ethanol with ultra-low metal ion concentration, according to the following steps:

[0037] 1. Take the distillate sample of Example 1 as the original sample of this example.

[0038] 2. Use PinAAcle 900T atomic absorption analyzer to test and analyze the exact concentration of potassium, sodium and copper ions in the above solution: potassium ion concentration is 0.24ppm, sodium ion concentration is 0.17ppm, copper ion concentration is 0.32ppm, and the data is recorded.

[0039] 3. Same as Example 1.

[0040] 4. Put the solution described in step 1 in round-bottom flask 6 for distillation, and the distillate is then subjected to sub-boiling distillation in Erlenmeyer flask 3. The distillation temperature of round-bottom flask 6 and Erlenmeyer flask 3 is controlled at 76.8±0.2°C. The distilled steam is condensed by the condenser 9 and the condensate is dripped into the receiving bottle 11, and the obtained condensate is ethanol with ultra-low metal ion con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com