Multi-functional high-temperature efficient energy-saving steam oven

A high-efficiency, energy-saving and multi-functional technology, applied in the field of stoves, can solve the problems of inconvenient maintenance, short flame and flue gas stroke, insufficient combustion firepower, etc., to improve steam generation efficiency, improve thermal efficiency utilization rate, and fully utilize fuel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

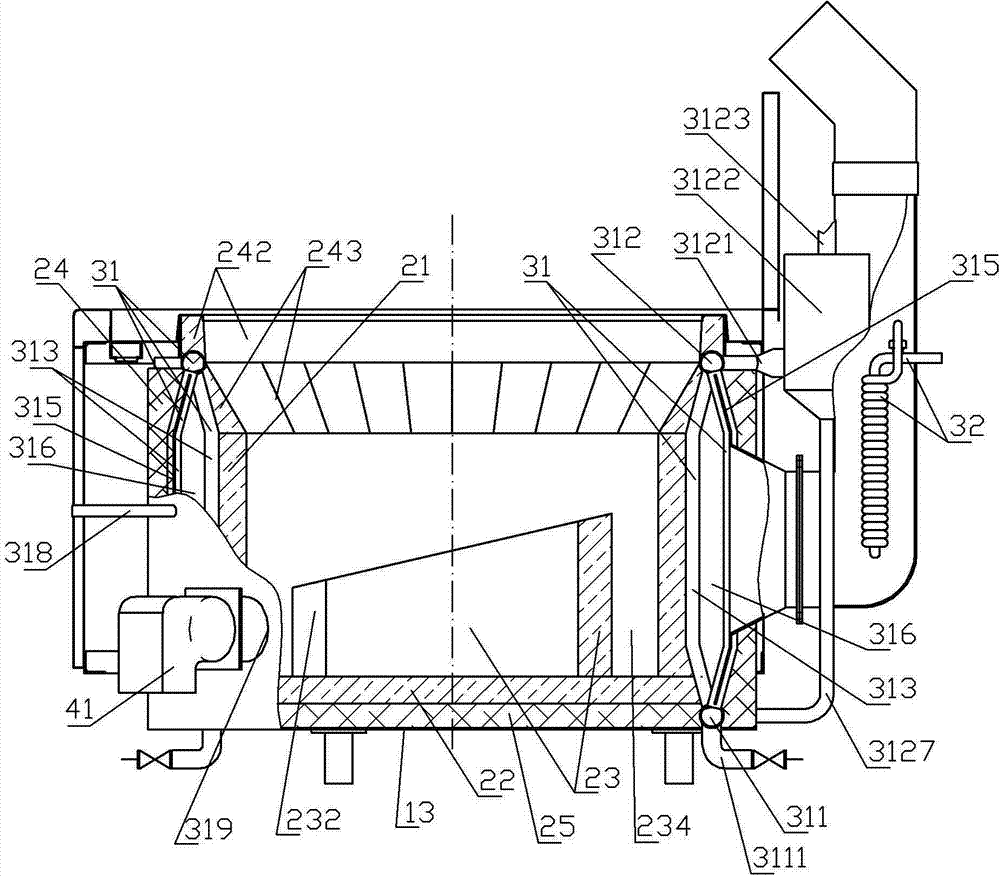

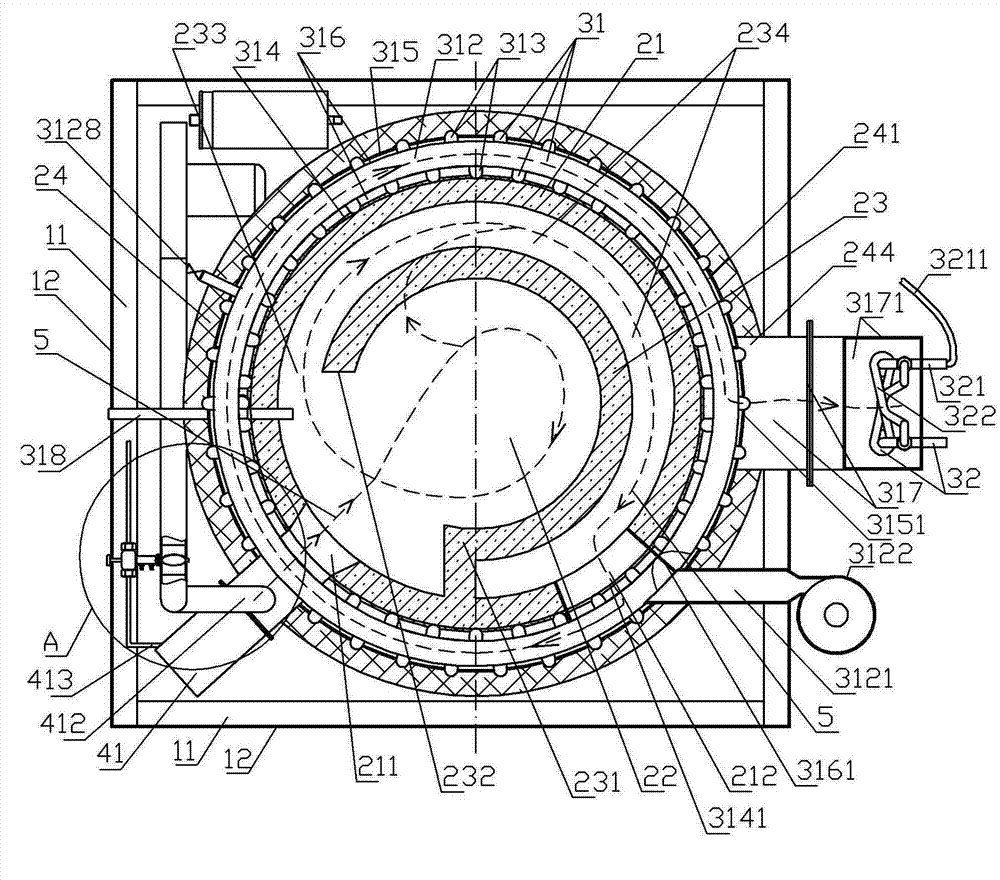

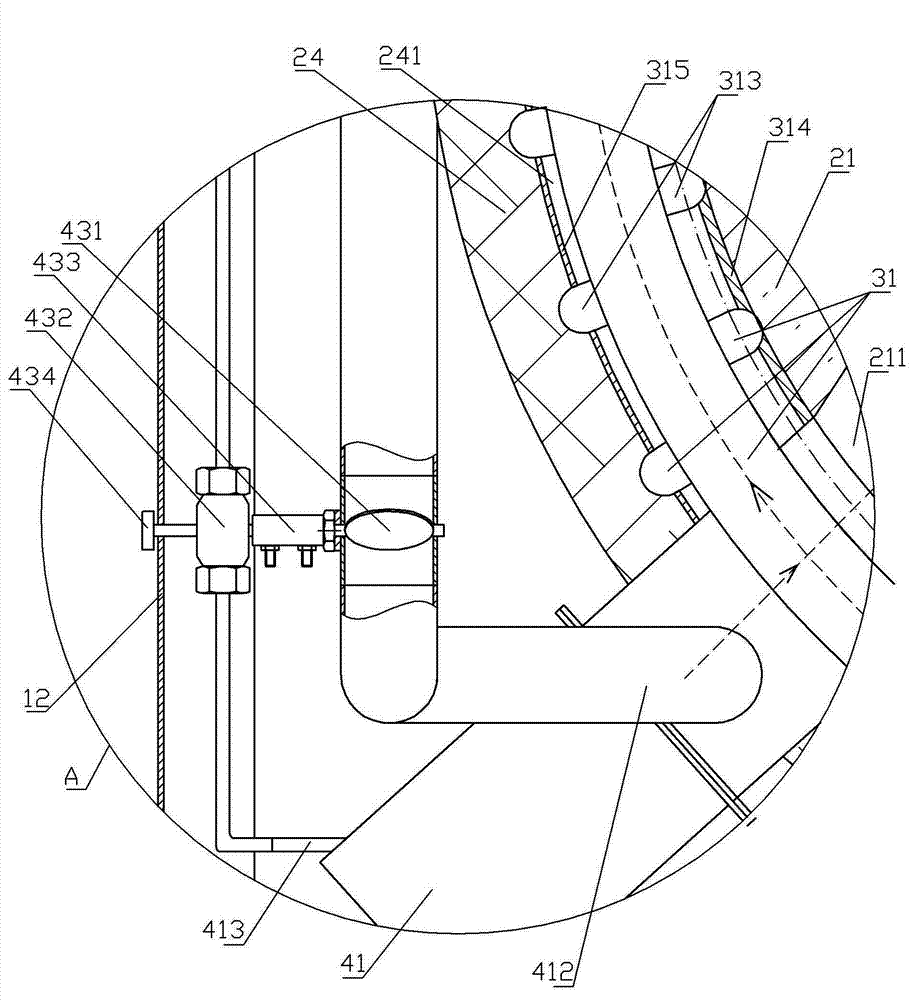

[0027] Such as Figure 1-4 Shown: a multifunctional high-temperature high-efficiency energy-saving steam stove, which includes a stove frame, a stove body, a steam system and a combustion system. The stove frame includes a bracket 11, a panel 12 and a bottom plate 13, and the panel 12 and the bottom plate 13 are installed on the outside of the bracket 11. The stove body is installed on the bracket 11 and located in the panel 12 and the bottom plate 13; the steam system includes a steam generator 31 and a cold water preheating device 32; the combustion system includes a burner 41, a blower 42 and a fuel and air synchronous control device.

[0028] The stove body includes a stove core wall 21, a stove bottom pad 22, a stove core swirl 23, an insulation wall 24 and a bottom insulation layer 25; , the flame inlet 211 is connected to the flame outlet of the burner 41; the bottom pad 22 of the stove is located under the core wall 21 of the stove; On the pad 22, its opening correspo...

Embodiment 2

[0042] Such as Figure 5-6 As shown: a multi-functional high-temperature, high-efficiency and energy-saving steam stove, the main difference between it and Embodiment 1 is that it is also equipped with an explosion-proof device, which includes a sleeve 61, a pressure relief cover 62, a guide rod 63 and a cover spring 64 The sleeve 61 includes a side wall 611 and a bottom plate 612, the side wall 611 of the sleeve 61 is welded to the bottom plate 31 of the stove rack, and the bottom plate 31 of the stove rack and the bottom of the stove body are provided with an explosion-proof opening 614 docked with the sleeve 61 (the bottom plate 31 of the stove rack, the bottom insulation layer 25, and the bottom pad 22 of the stove have corresponding explosion-proof openings respectively), the upper opening of the sleeve 61 is connected with the bottom plate 31 of the stove rack and the explosion-proof opening 614 at the bottom of the stove body, and the sleeve The bottom plate 612 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com