Efficient cooling swivel joint

A cooling, rotating and efficient technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing elements, etc., can solve the problems of rapid cooling of rolls, inability of cooling medium, loss of elasticity of springs, etc., to reduce failures rate, cooling effect increase, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

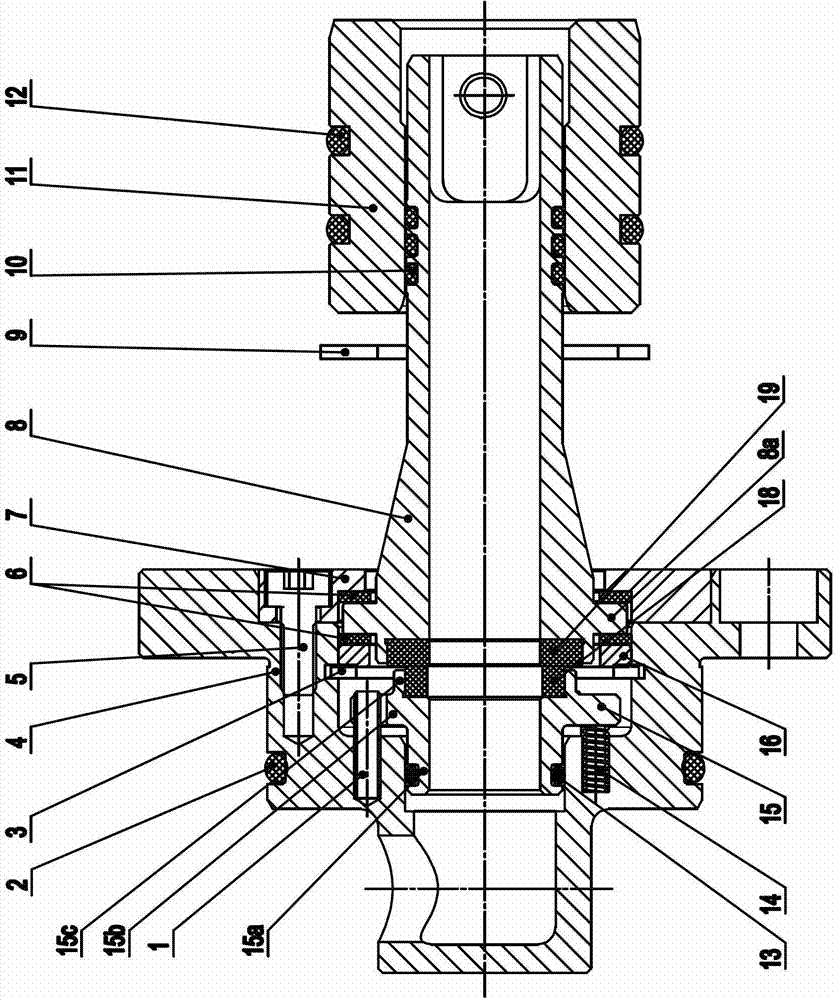

[0022] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0023] As shown in the figure: the high-efficiency cooling rotary joint in the embodiment is mainly composed of the anti-rotation pin 1, the first O-ring 2, the retaining ring 3 for the first hole, the shell 4, the hexagon socket head screw 5, and the wear-resistant gasket 6. Cover 7, outer tube 8, retaining ring for the second hole 9, second O-ring 10, transition sleeve 11, third O-ring 12, fourth O-ring 13, small spring 14, static ring seat 15. Adjusting gasket 16, cylindrical pin 17, static sealing ring 18, dynamic sealing ring 19 and other components.

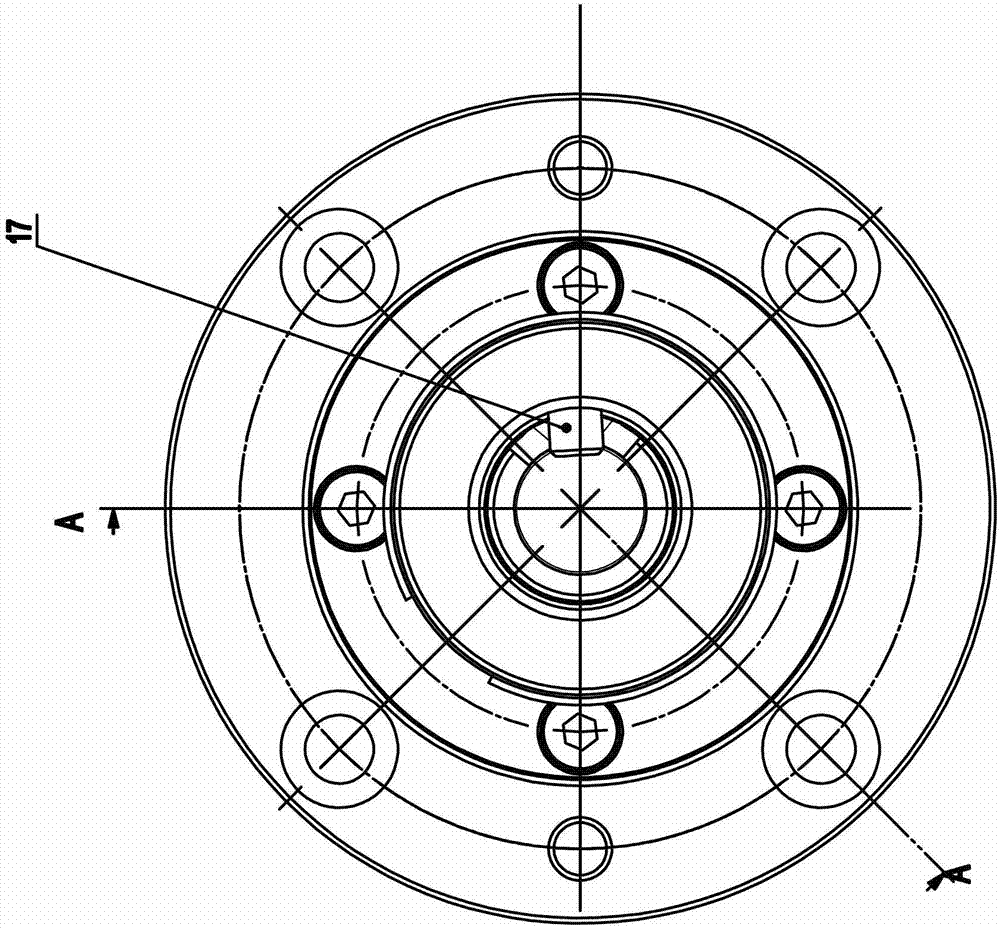

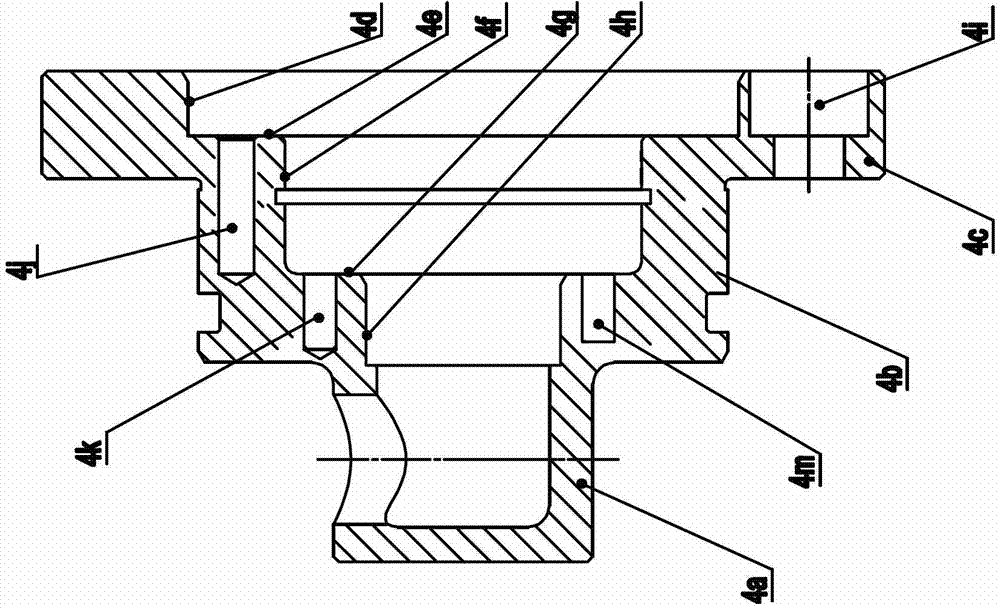

[0024] Such as figure 1 , image 3 As shown, the shell 4 is divided into a shell thin section 4a, a shell middle section 4b and a shell flange section 4c according to different outer diameters. The radial through hole communicates with the inner hole of the casing 4; the thin section 4a of the casing and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com