A power battery vacuum drying equipment

A technology of vacuum drying equipment and power batteries, which is applied in the direction of drying chamber/container, drying gas arrangement, local stirring dryer, etc. It can solve the problems of low drying efficiency, drying effect not meeting the process requirements, low degree of automation, etc., to achieve Effect of reducing power consumption, improving drying efficiency and drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the specific embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

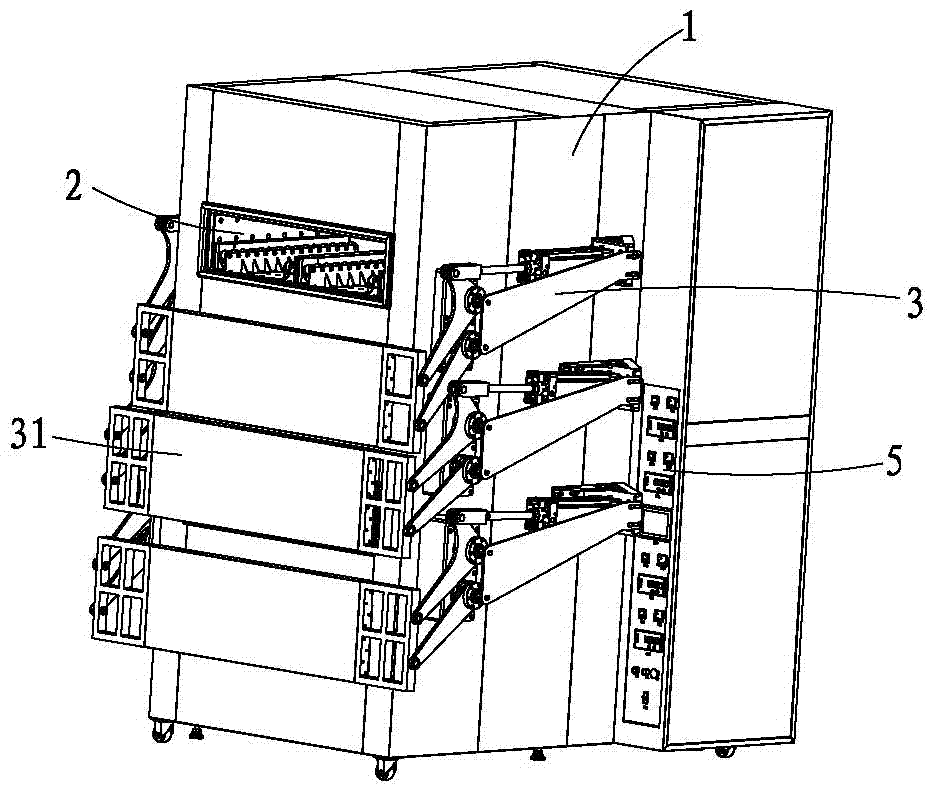

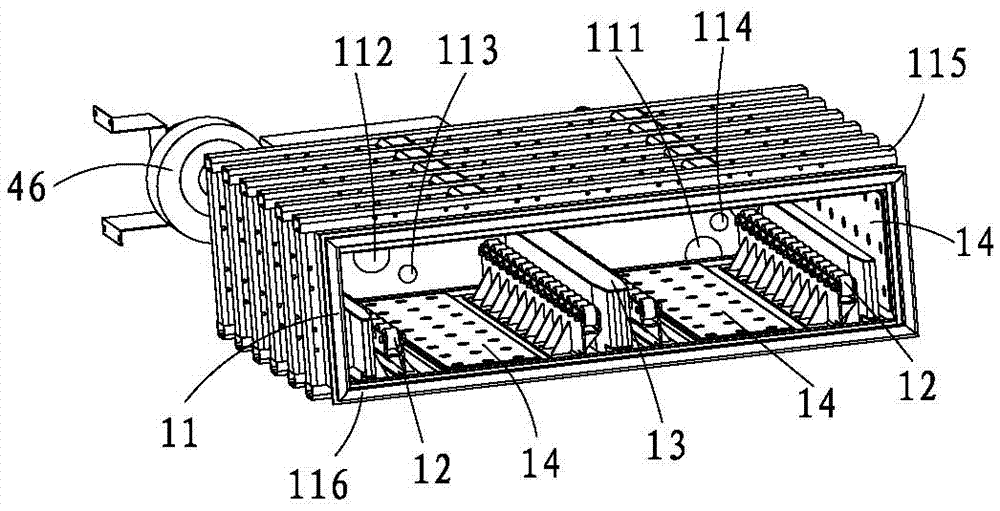

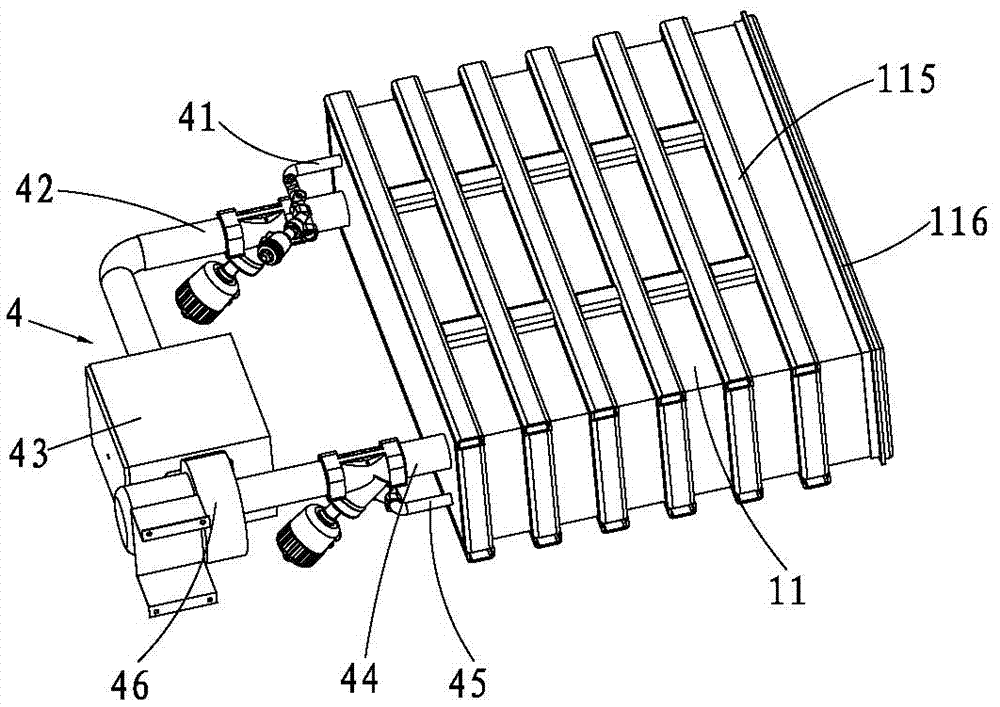

[0022] Such as Figure 1~4 As shown, a power battery vacuum drying equipment includes a box body 1, a furnace cavity 2 arranged in the box body 1, a furnace door mechanism 3 cooperating with the furnace cavity 2, an air delivery system 4 communicated with the furnace cavity 2, and a The control part 5 on the side of the box body 1, the furnace chamber 2 includes a furnace chamber body 11, a loading track 12, a loading tray isolation plate 13 and a mica sheet 14, a loading track 12, a loading tray isolation plate 13 and a mica sheet 14 They are all arranged in the furnace chamber body 11. The furnace chamber body 11 is arranged in a square structure, and there are several mica sheets 14 arranged on the four surfaces of the inner wall of the furnace chamber body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com