Method for calculating shear capacity of reinforced concrete flexural beam

A technology of shear bearing capacity and calculation method, which is applied in the field of reinforced concrete beams, can solve the problems that the calculation model is not representative, the parameters of the bearing capacity of the oblique section of RC beams cannot be fully considered, and the number of test pieces is limited, etc., so as to achieve practicability strong, accurate prediction results, and reasonable calculation models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] (1) Selection of test materials

[0068] The cement used in the test is P.Ⅱ42.5R Portland cement, and the water is tap water. Table 1 shows the basic properties of the cement part provided by the manufacturer.

[0069] Table 1 Basic properties of cement

[0070]

[0071] The river sand used in the test is medium sand, and its sieving test conditions and related properties are shown in Table 2 and Table 3, respectively.

[0072] Table 2 Screening results of sand

[0073]

[0074] The fineness modulus of sand (M x ) is calculated according to the following formula:

[0075]

[0076] Table 3 Basic properties of sand

[0077]

[0078] Continuously graded gravel with a nominal particle size of 5-25mm was used in the test, and the screening test conditions and related performances are shown in Table 4 and Table 5, respectively.

[0079] Table 4 Screening results of stones

[0080]

[0081] Table 5 Basic properties of stones

[0082]

[0083] The long...

Embodiment 2

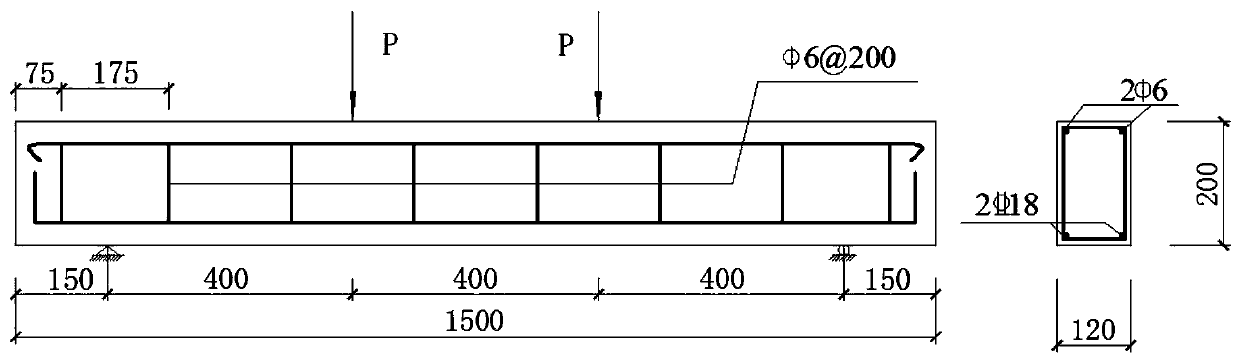

[0164] (1) Test piece design

[0165] 14 beams were designed for the test, and the parameters are shown in Table 10.

[0166] Table 10 Test beam design parameters

[0167]

[0168]

[0169] In general, concrete plays a large role in the shear capacity of reinforced concrete beams. Therefore, in order to clearly reflect the influence of the corrosion of stirrups and longitudinal bars on the shear capacity of reinforced concrete beams, the strength grade of concrete was reduced as much as possible in this test, and the strength grade of concrete was designed according to the requirements of C20. The concrete mix ratio is cement: sand: stone: water = l: 2.5: 3.36: 0.55.

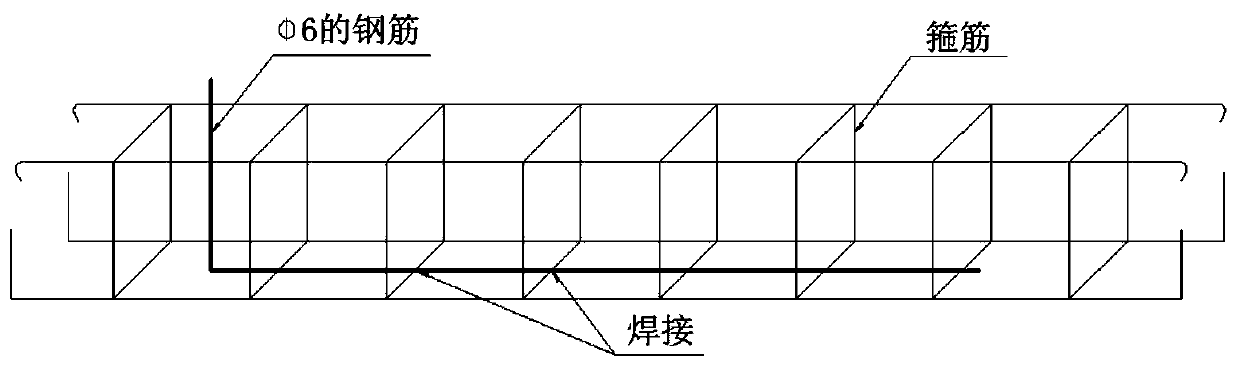

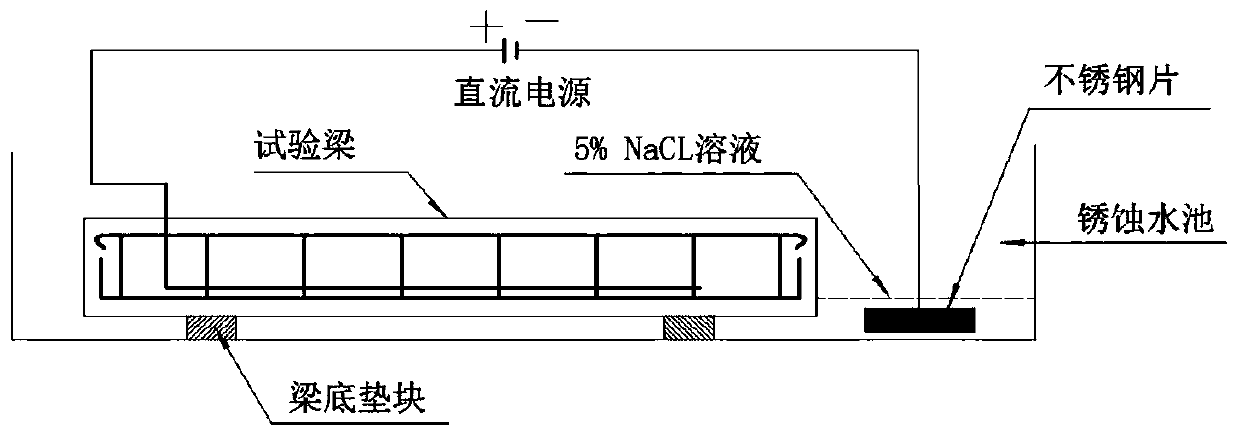

[0170] A total of 14 reinforced concrete simply supported beams were produced, which were divided into three types: 6 beams with corroded stirrups (numbered L1~L6), 6 beams with corroded longitudinal bars and stirrups (numbered LT~L12) and 2 beams with corroded stirrups For non-corroded (numbered L13, L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com