Improved lifter used for building panel production

A technology of building boards and elevators, which is applied in the direction of transportation, packaging, rollers, etc., can solve the problems of low demoulding efficiency and affect the production process, and achieve the effects of firm fixation, improved production efficiency, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

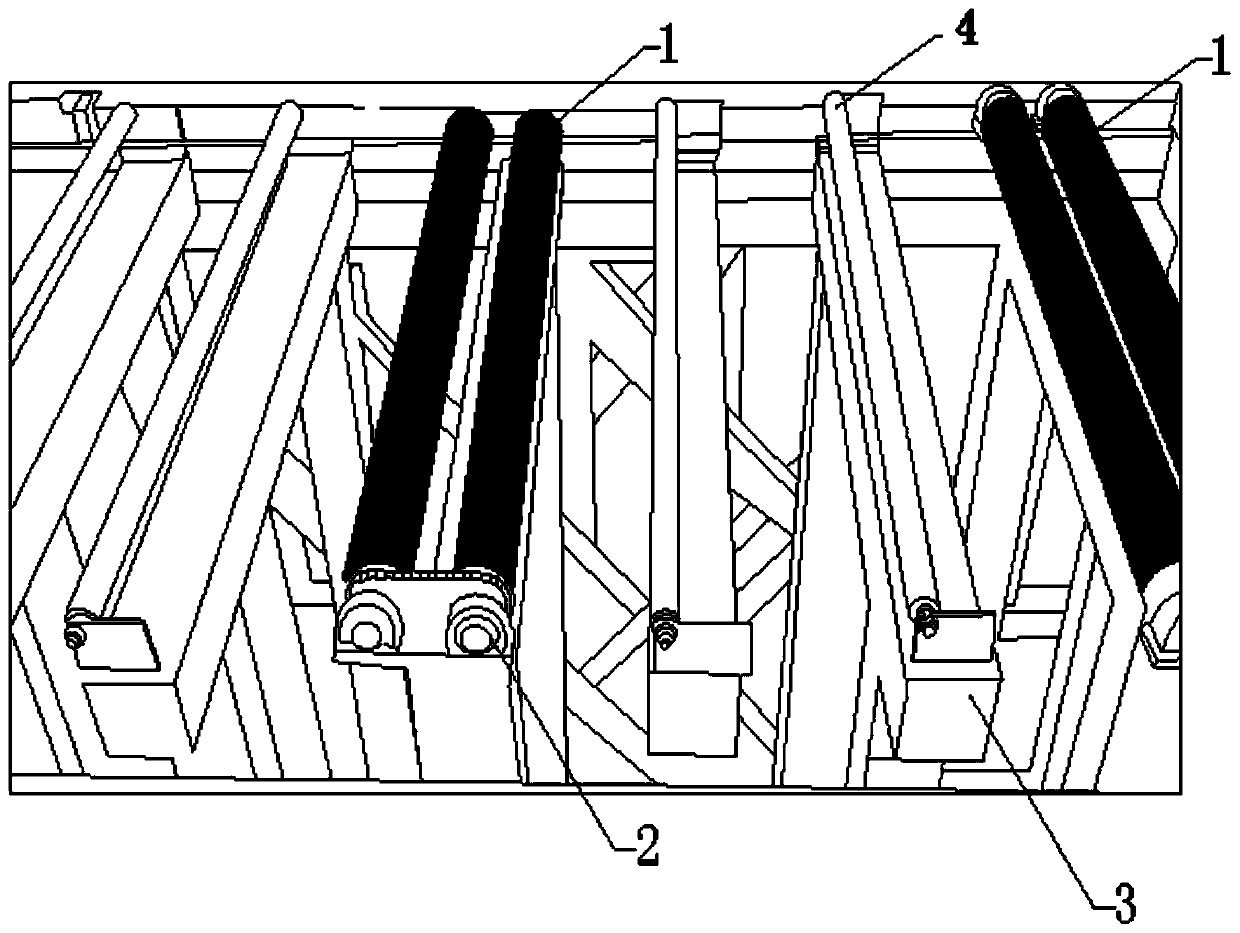

[0026] The improved building board production elevator of the present embodiment, please refer to figure 1 As shown, it includes a bracket in a frame structure, and the bracket includes two first guardrails along the length direction and two second guardrails along the width direction arranged in up and down positions; between the two first guardrails along the two second guardrails The width direction of the two guardrails is provided with several fixed pile foundation structural parts 3, and the several pile foundation structural parts 3 are arranged in parallel with each other at intervals:

[0027] The pile foundation structural member 3 is provided with several connecting rods arranged along the direction of the second guardrail and a roller for transmission: the connecting rod is arranged above the pile foundation structural member through a fixed baffle;

[0028] The rollers include two first rollers 1 and second rollers arranged in parallel at intervals, both ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com