Butt joints, prefabricated components and piers

A technology of prefabricated components and connectors, applied in the direction of connecting contact materials, clamping/spring connections, bridges, etc., can solve the problem that lightning protection structures cannot be effectively connected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

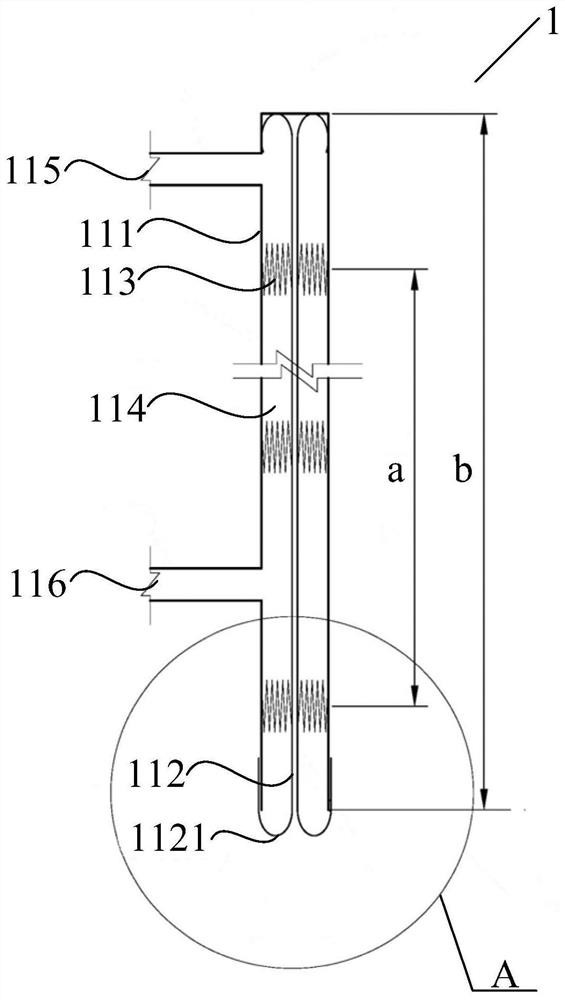

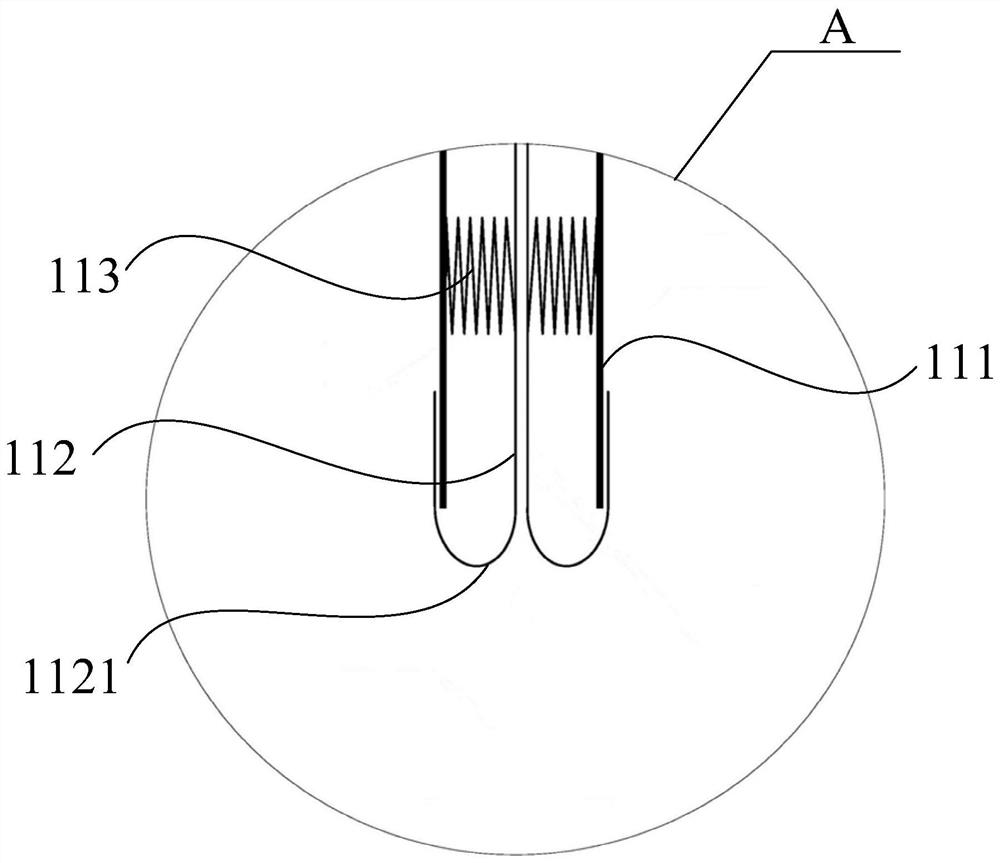

[0045]Such as figure 1 , figure 2 As shown, the embodiment of the present application provides a butt connector 1, the butt connector 1 includes a positioning steel pipe 111, and at least two contact conductive pieces 112 and a plurality of elastic members 113 arranged inside the positioning steel pipe 111;

[0046] The two opposite contact conductive pieces 112 are respectively installed on the inner sidewall of the positioning steel pipe 111 through at least two elastic members 113 arranged along the length direction of the positioning steel pipe 111, and each contact conductive piece 112 is in the direction of the length of the butt joint 1. The edges are respectively bent in directions away from the central axis of the positioning steel pipe 111 .

[0047] Furthermore, using the positioning steel pipe 111 to insert other parts can not only realize the connection with other parts, but also realize the positioning function; the contact conductive pieces 112 are fixed by th...

Embodiment 2

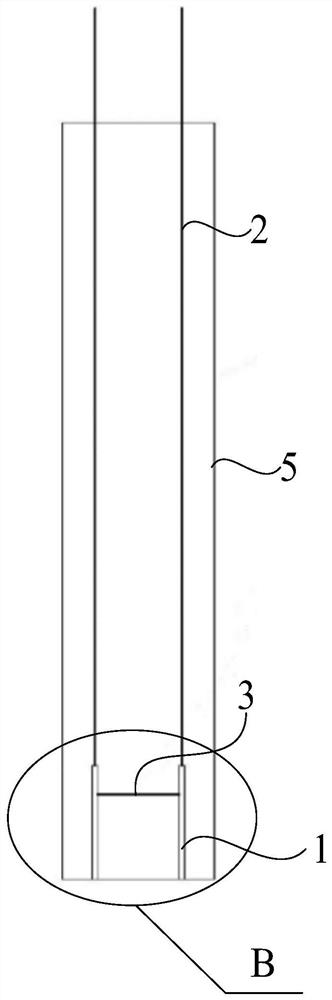

[0055] Such as Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, the embodiment of the present application provides a bridge pier, including the butt connector 1 in the first embodiment, and the down conductors 2 are respectively pre-embedded in the column 5, the cover beam 6 and the cap 7 of the bridge pier;

[0056] One end of the down-conductor 2 protrudes from the surface of the column 5 of the bridge pier, the cover beam 6 and the platform 7 respectively, and the other end of the down-conductor 2 that does not extend out of the surface of the column 5 and the cover beam 6 is connected with the butt joint 1 respectively. One end of the positioning steel pipe 111 is welded and connected, and the surface of the other end of the positioning steel pipe 111 is flush with the other surface of the column 5 and the cover beam 6;

[0057] Among them, the down conductor 2 adopts a specially designed flat steel, and the material and cross-sectional size should ...

Embodiment 3

[0070] Such as image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the embodiment of the present application provides a prefabricated component with lightning protection function, including the butt connector 1 in Embodiment 1, and at least one downconductor 2 that can be inserted into the butt connector 1, the butt connector 1 and the butt connector 1. The down conductors 2 are all arranged in the prefabricated components;

[0071] Wherein, one end of the down conductor 2 protrudes from the surface of the prefabricated component, and the other end is welded to one end of the positioning steel pipe 111 of the butt connector 1, and the surface of the other end of the positioning steel pipe 111 is flush with the other surface of the prefabricated component.

[0072] Specifically, welding connection is adopted between the down conductor 2 pre-embedded in the same component and the positioning steel pipe 111, and a plug connection is used between the down conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com