Pushing rolling mechanism and walking-vehicle bottom frame

A traveling vehicle and underframe technology, which is applied in the directions of motor vehicles, substructures, vehicle components, etc., can solve the problems of increasing the energy loss of driving vehicles, occupying a large space for traveling vehicles, and driving tank trucks intermittently, and achieves smooth fluctuation and versatility. Strong, low resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

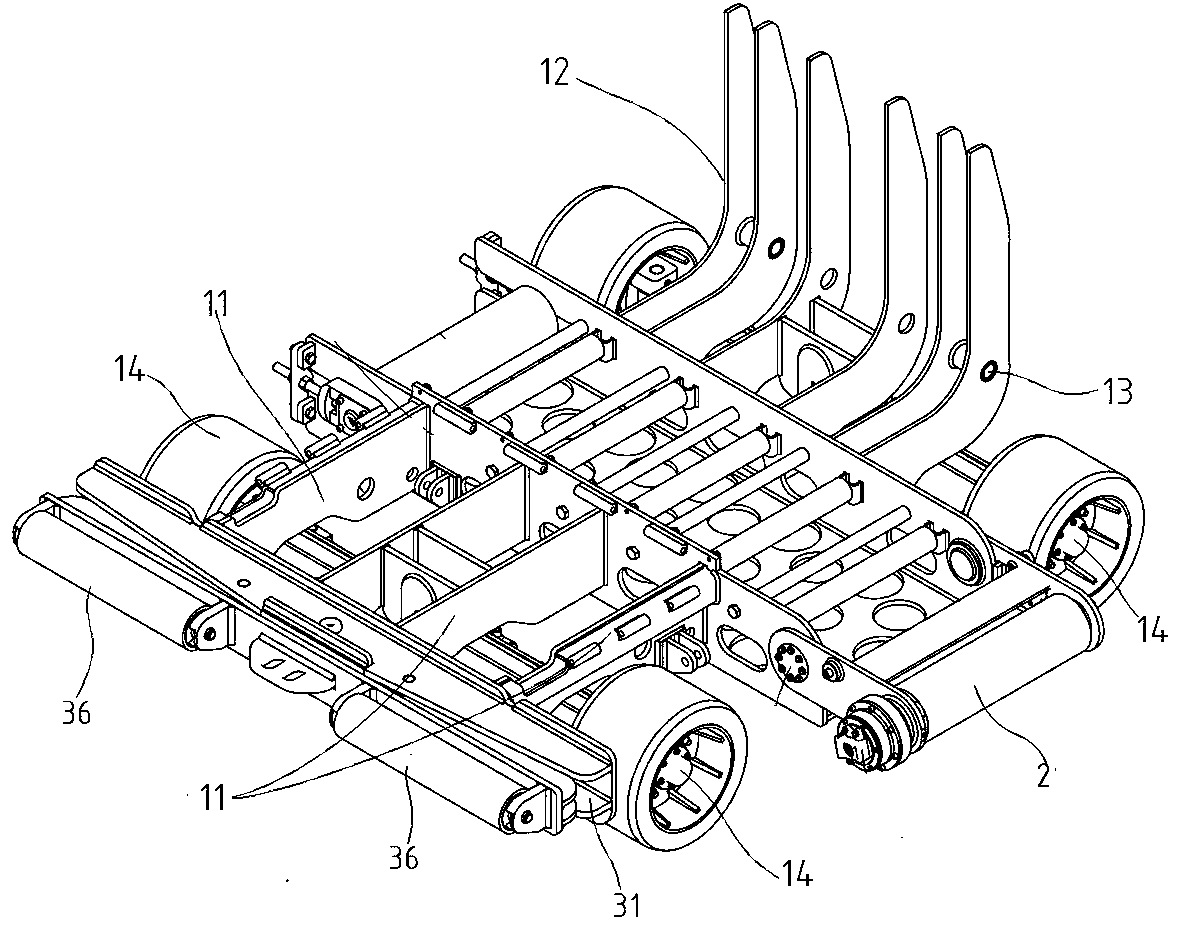

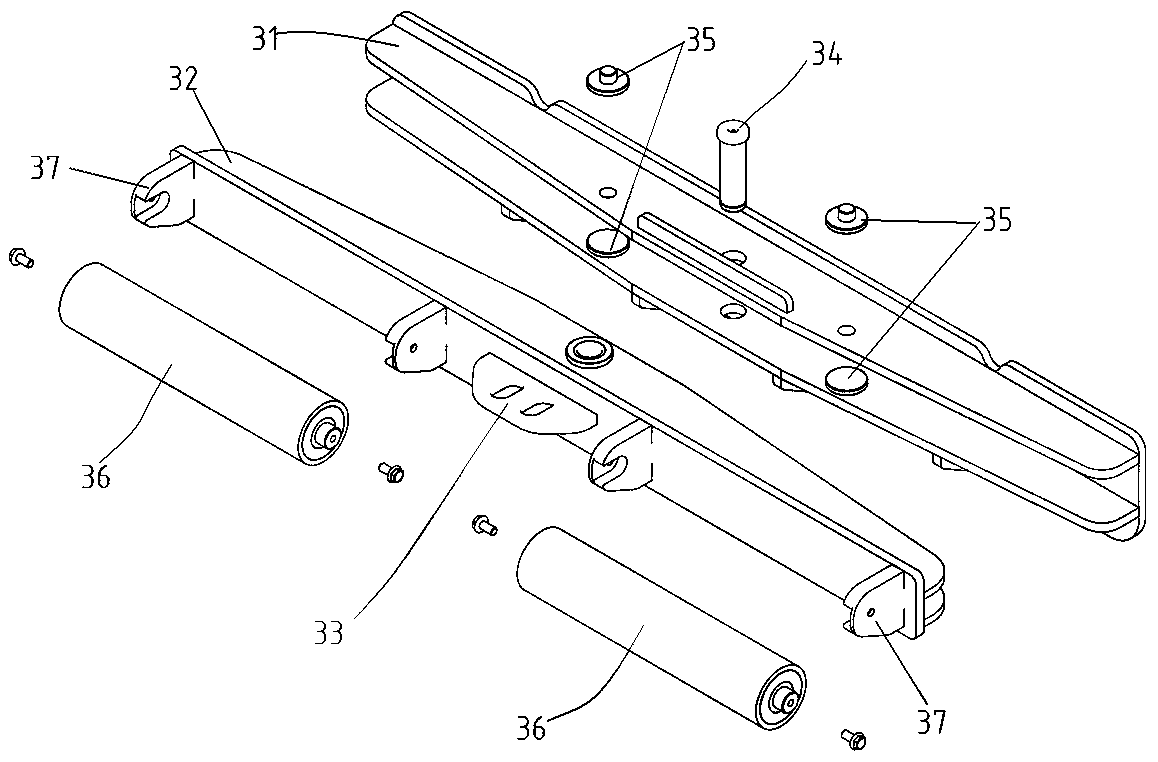

[0028] Embodiment 1, the rolling mechanism 3 is fixedly connected to the bottom frame. The rear end of the pushing and rolling mechanism 3 is provided with an inserting arm 31 connected with the chassis and fixed with a bolt. The above-mentioned underframe of the traveling vehicle also includes several rear beams 12 arranged in parallel, a conveying mechanism 2 is provided between the front beams 11 and the rear beams 12 , and a rear bridge 123 is provided below the rear beams 12 .

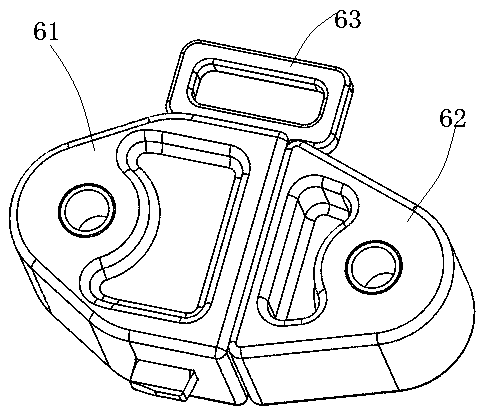

[0029] The above-mentioned trolley underframe, the rear end of the underframe is provided with a pin block to connect the drive car for providing power, the pin block includes a groove pin block 61, a boss pin block 62 and a pin 63, the Groove pin block 61 is hinged at the front end of the driving car, and described boss pin block 62 is hinged at the bottom frame rear end, and is fixed with described pin 63 after groove pin block 61 and boss pin block 62 are inserted and matched.

Embodiment 2

[0030] Embodiment 2. The difference between this embodiment and Embodiment 1 is that the push-rolling mechanism 3 and the bottom frame are connected through an adjustable plug-in connection through the connecting arm 38, and the connecting arm 38 is plugged into the bottom frame through a bolt. , The plugging position can be adjusted as required, and the assembly position of the push-roll mechanism 3 can be adjusted according to the front unloading wheel base under different working conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com